Coal washing is an indispensable process in coal deep processing. The coal mined directly from the mine is called raw coal.The raw coal is mixed with many impurities in the mining process, and the quality of coal is different. Coal with a low intrinsic ash content and coal with a high intrinsic ash content will mix. Coal washing is an industrial technique that removes impurities from raw coal, or classifies high-quality coal from inferior coal.

The products produced after the coal washing process are generally divided into gangue, medium coal, grade B clean coal, and grade A clean coal. The finished coal after the coal washing process is usually called clean coal. Coal washing can reduce the cost of coal transportation and increase the utilization rate of coal. Cleaning coal is generally an energy source that can be used as fuel. Cleaning coal is generally used for coking, which needs to remove sulfur and impurities in industrial processes to meet the standards for coking.

The purpose of removing gangue in coal is to prevent it from melting and forming agglomerates during high-temperature combustion, which can easily block the furnace or other combustion facilities, and it does not burn to reduce the heat of combustion and affect efficiency.

Selection and arrangement of explosion-proof lighting fixtures

The system layout of the coal preparation plant is relatively complicated, and the architectural design such as screening and crushing, the main plant, and the belt conveyor trestle have their own characteristics. Therefore, in its lighting design, it is first necessary to determine the selection of lamps of a certain model and power, and then reasonably determine the arrangement of lamps and the number of lamps.

- Flameproof enclosure type: The raw coal system should use LED explosion-proof lamps.

- Waterproof and dustproof type: Waterproof and dustproof lamps should be used in other workshops.

- Anti-corrosion type: It is necessary to specify that the flotation reagent storehouse should be selected anticorrosive lamps.

- Shock-proof and anti-falling: Shock-proof lamps should be used in places with heavy vibrations such as forging hammers and large bridge cranes, and anti-falling measures should be taken for lamps used in places with large swings.

CESP LED explosion-proof lighting application in coal mine:

CESP high-quality explosion-proof led lamps can be used in Zone 1 and Zone 21, Class I Class 1 and Class 2, and Class II Class 1 and Class 2 hazardous locations. They are very suitable for lighting in coal washing plants.

|

Lamp type |

Lamp picture |

Application area |

|

Trestle roads, on-site roads, unloading dockes, loading docks, etc. |

||

|

Storage yard, belt conveyor corridor, transfer building, shipping dock, etc. |

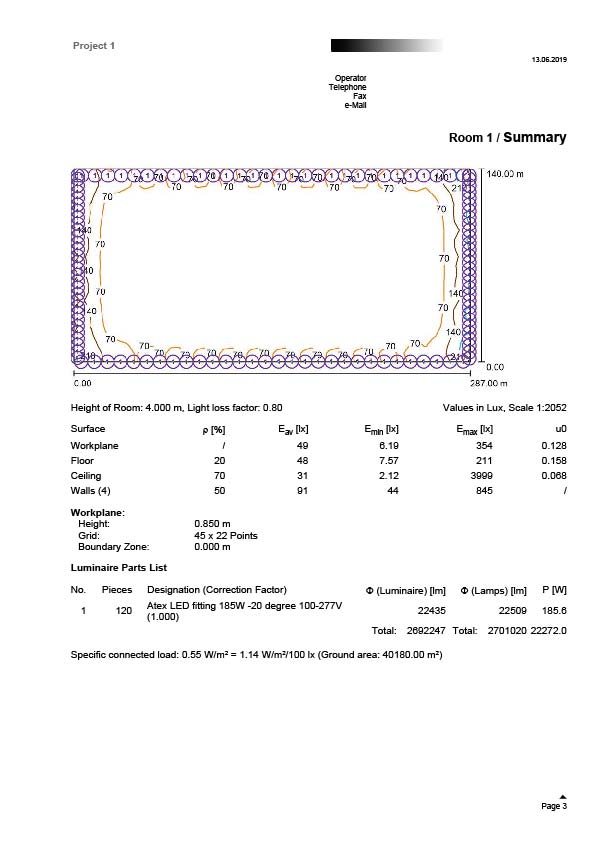

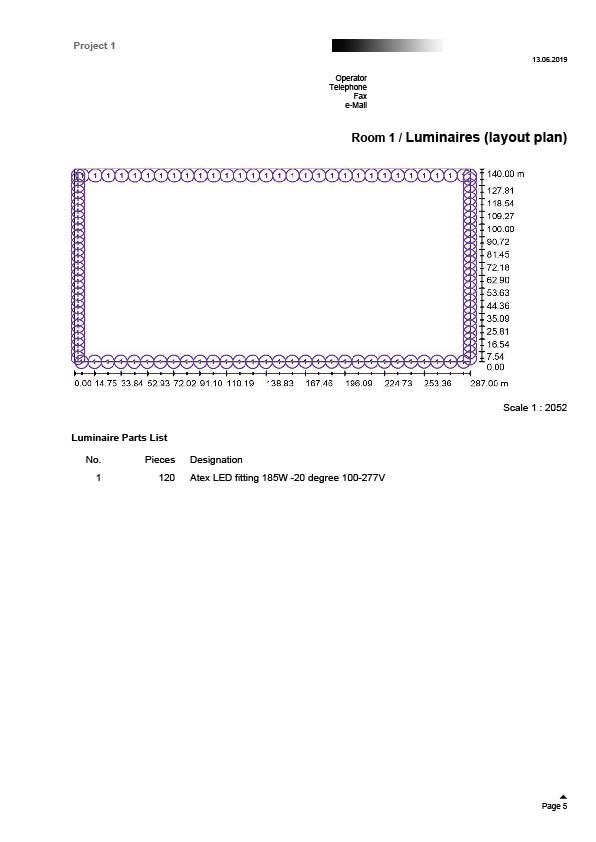

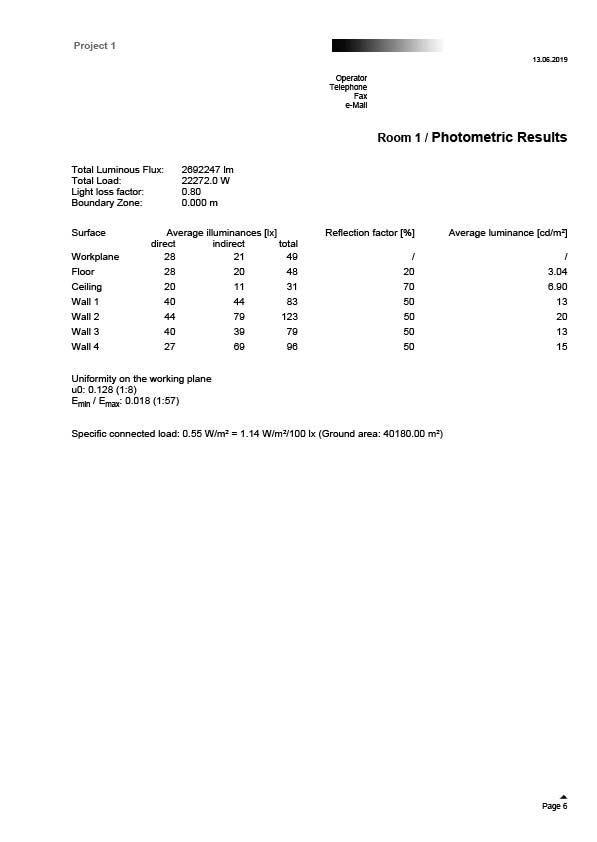

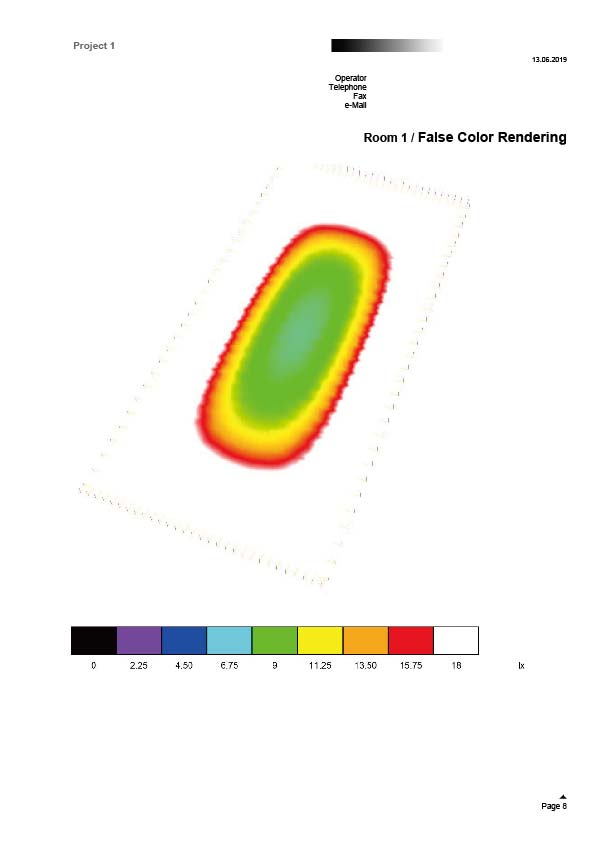

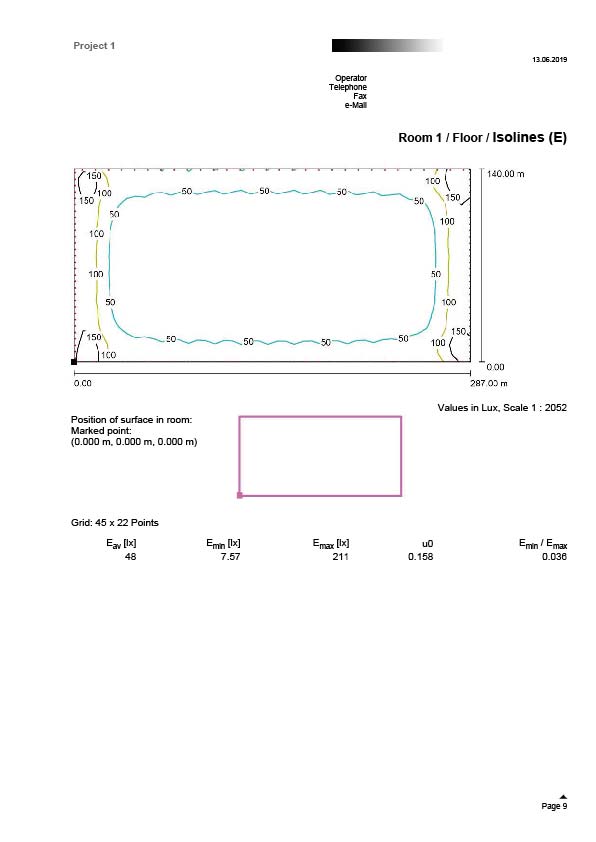

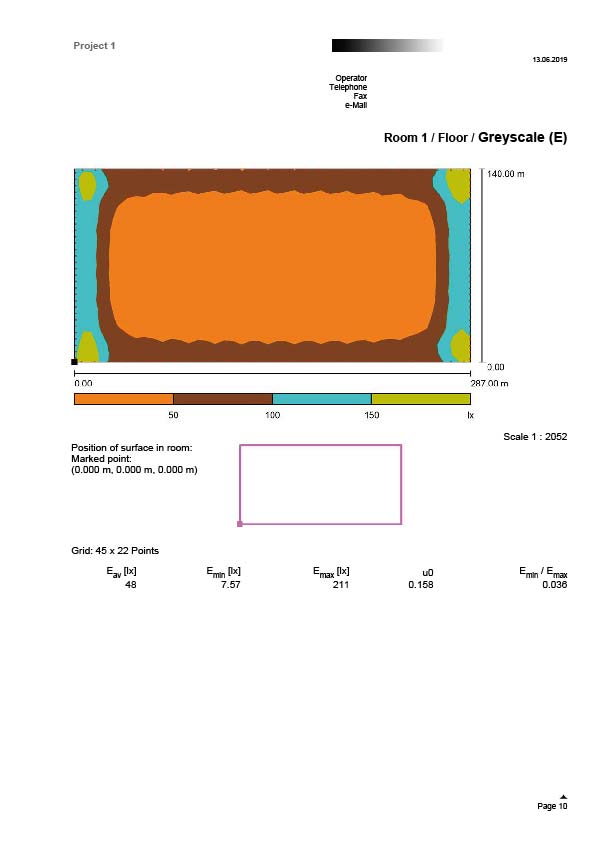

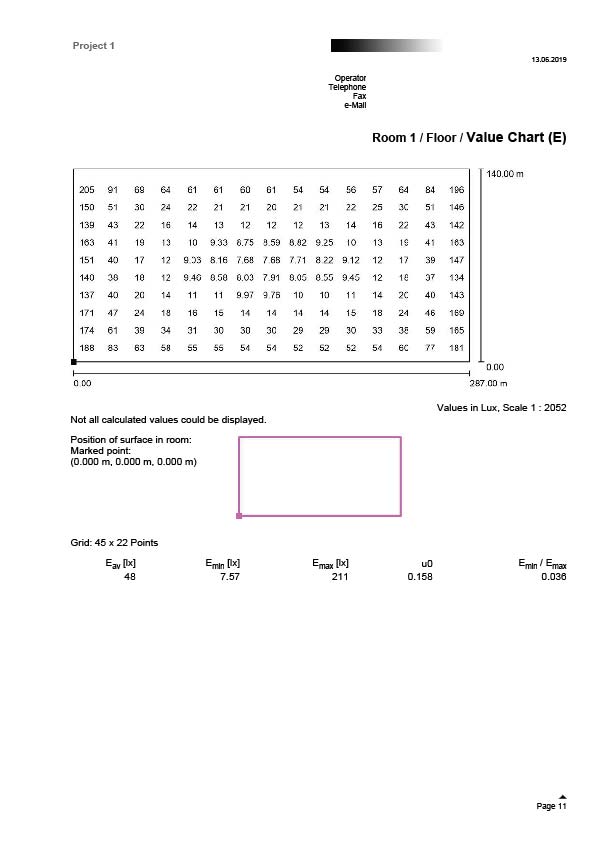

185W LED explosion-proof lighting design reference for coal mine lighting: