In the maintenance of oil tank area, we need to pay attention to some matters to ensure the safety of maintenance personnel and the smooth maintenance work.

- The storage tanks storing flammable gas and flammable liquid should be equipped with necessary fire fighting equipment. Smoking, lighting and heating with open flame are strictly prohibited in the tanks, and the ignition source is prohibited to be brought into the tank area.

- For storage tanks with inflammable, explosive, toxic, corrosive and other media, the relevant regulations of dangerous goods management shall be strictly implemented.

- Before the inspection and repair of the storage tank, the power supply of the electrical equipment related to the storage tank must be cut off, and the equipment handover procedures must be completed.

- After the internal media of the storage tank is drained, the inlet and outlet valve should be closed or the blind plate should be added to cut off the pipeline and equipment connected with it, and there is an obvious partition sign.

- For storage tanks containing flammable, corrosive, toxic, or asphyxiating media, they must be replaced, neutralized, disinfected, cleaned, etc., and analyzed and inspected after treatment. The analysis results should meet the provisions of relevant specifications and standards. It is strictly prohibited to use air replacement with flammable medium.

- 30 minutes before entering the tank operation to sample analysis, its oxygen content is between 18-23%(volume ratio).

- When entering the tank to clean up toxic and corrosive residue, wear personal protective equipment.

- Need to build the scaffold and lifting device, must be firm and reliable, in the operation is strictly prohibited to throw material tools inside and outside, in order to ensure safe operation.

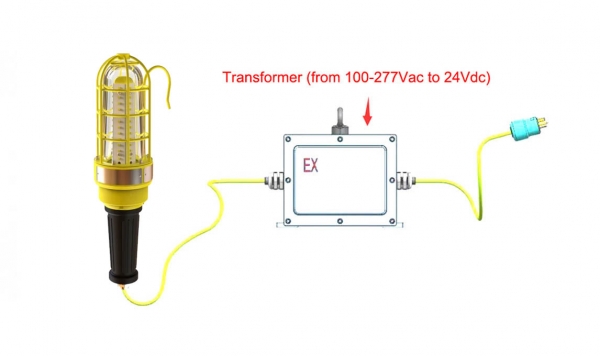

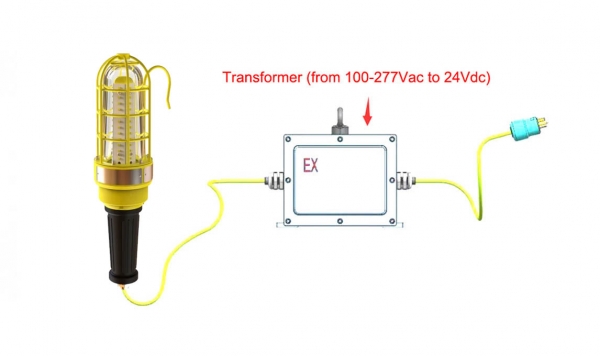

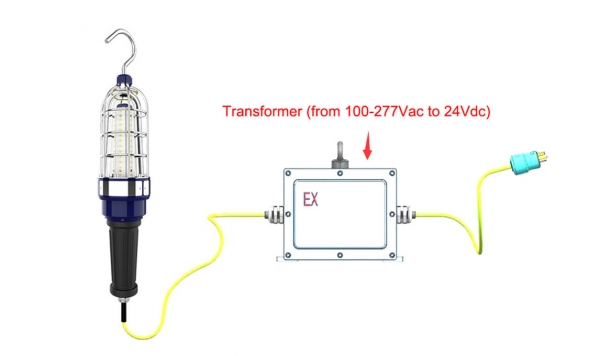

- The tank lighting should use the voltage is not more than 24Vexplosion-proof lamps.

CESP SC-series explosion proof led hand lamp is suitable for the inspection working in the hazardous location. ATEX IECEX Zone 1 Zone 21 and UL844-Class 1 Division 1 approved.

- Tank operations must have guardians, and reliable contact measures.

- At the time of completion, maintenance personnel and guardianship personnel jointly check the inside and outside of the tank. After it is confirmed, the guardian can close the manholes only after signing the operation certificate in the tank.