- Cold storage building and thermal insulation characteristics

Cold storage: a warehouse that uses cooling facilities to create suitable humidity and low temperature conditions. Also known as cold storage. It is a place for processing and storing products. It can overcome the influence of climate, prolong the storage period of various products, and regulate market supply.

Cold storage is a storage building group with artificial cooling and cooling functions, including warehouse, refrigeration room, power transformation and distribution room, etc. In order to ensure that the temperature in the cold storage room is maintained within the specified range, the building envelope is often set with a certain thickness of the thermal insulation layer according to the storage temperature requirements. The good flame retardant performance of thermal insulation materials is one of the important factors to decrease the fire accident of cold storage. Before the 1980s, the commonly used thermal insulation materials in cold storage were cork and rice husks. Because of its high moisture absorption, easy decay after pyrolysis, and easy decomposition and combustion at high temperature, it was gradually superseded by EPS,PU and XPS.

According to the different building structures, cold storage can be divided into civil cold storage, combined cold storage, mixed cold storage, etc. The civil cold storage adopts reinforced concrete as the support structure of the warehouse, and its enclosure structure is brick concrete material with additional thermal insulation material. The combined cold storage adopts light steel structure as the supporting structure of the building, and the insulation material (combined cold storage insulation board) with a certain thickness of steel plate attached on both sides is the enclosure structure of the warehouse. The hybrid cold storage is usually a multi-layer cold storage, its structure body is reinforced concrete, and the box body is made of composite cold storage insulation board.

- Problems in cold storage

- Most warehouses use old-fashioned civil structures without beams

- Cold storage hall, platform design for open type

- Configuration of cold storage equipment

- Poor overall management of cold storage facilities

- Storage facilities backward

- Insufficient number of new combined cold stores

- Common accidents in cold storage

- Fire accident

In recent years, there have been frequent fires in the freezing storage industry, especially in an explosion-proof cold storage last year, which caused a great number of casualties and caused great losses to the safety of people's lives and property.

- Refrigeration system accident

Nowadays, most refrigerators utilize freon refrigeration. Freon belongs to grade IV mild toxic substances. Now most refrigerators use freon refrigeration. Freon belongs to grade IV toxic substances. However, the content of freon in the air reaches a certain degree, which can cause asphyxia. When the concentration of ammonia in the air is between 16% and 25%, explosion accidents may occur in case of open fire . Due to the frequent occurrence of quality accidents in cold storage systems, compressor damage and refrigerant leakage, many losses have been caused to enterprises.

- Cause analysis of common accidents

- Cause of fire accident

Combustibles, fire sources and combustion supporting materials are the three inevitable factors that cause the combustion of combustibles in a fire. As combustion supporting gas exists in the atmosphere, the causes of cold storage fire can only be analyzed from two aspects of combustible materials and fire source.

The thermal insulation materials for the pipes of cold storage buildings and equipment are the worst combustibles in the warehouse. Among the building materials used in the existing cold storage, the thermal insulation material of the cold storage has the highest combustion performance. Some common cases, such as Fengfeng poultry Co., Ltd. and Food Co., Ltd., are all caused by the burning of thermal insulation materials. In addition, in the early 1990s, the welding operation outside a prefabricated cold storage warehouse in a city caused a fire of the insulation material of the refrigeration pipeline, which rapidly expanded to the insulation wall of the cold storage along the insulation pipe, causing the cold storage fire and the steel structure of the cold storage collapsed. The main body of combustibles is the insulator.

The main causes of fire accidents in cold storage are electric gas welding, cutting operations, short circuits of cable, illegal use of open fire and so on. In 2015, there were 54 cold storage fire accidents, of which 65% were caused by electrical welding, cutting and other operations ;6% were caused by illegal use of open fire ;29% were caused by short circuit of electrical lines ;29% were caused by strong concealment; and 6% were caused by carelessness.

- Failure of refrigeration system

The cause of failure of refrigeration unit can be divided into refrigeration system without reasonable maintenance, often small work, running with disease, after the construction of cold storage, must not ignore, resulting in equipment annual inspection is not up to standard, aging accelerated, Thus occurs the refrigeration system ammonia refrigerant exposure phenomenon. Secondly, the cold storage design project is not perfect, unlicensed design, no professional technology installation construction, some cold storage cost is low, some cold storage construction enterprises choose a large number of defective or second-hand materials, so that the safety of cold storage can not be effectively guaranteed.

Normal use of cold storage fires, insufficient air, inadequate combustion, high carbon monoxide content. The acute lethal concentration of carbon monoxide is only 0.5, colorless and tasteless, and the activity is very strong. If the personal protection of firefighters is not in place, acute poisoning easily occurs. Accordingly, the equipment and facilities of the cold storage should select some mechanical products that meet the requirements of safety certification, such as UL、CSA、ETL、IECEx-CB certification, so as to avoid accidents caused by fire, poisoning and other auxiliary equipment caused by the equipment itself.

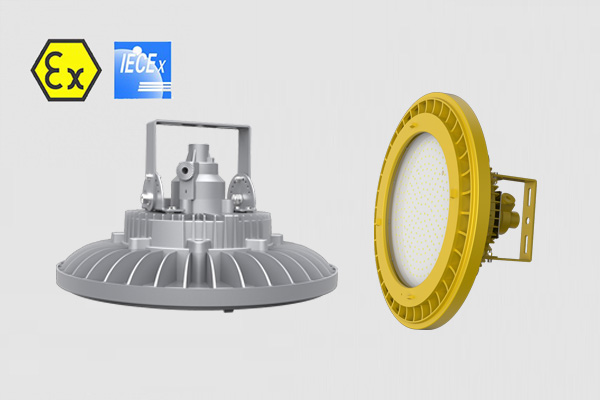

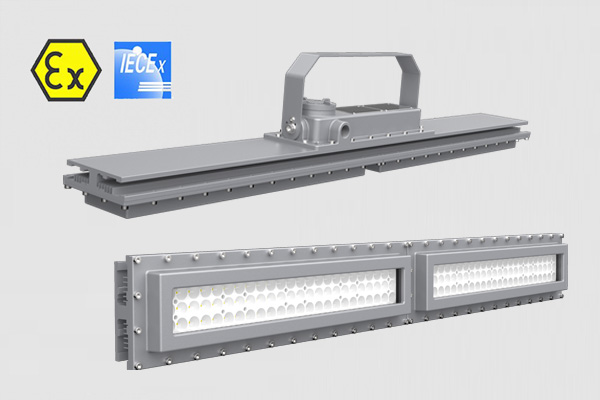

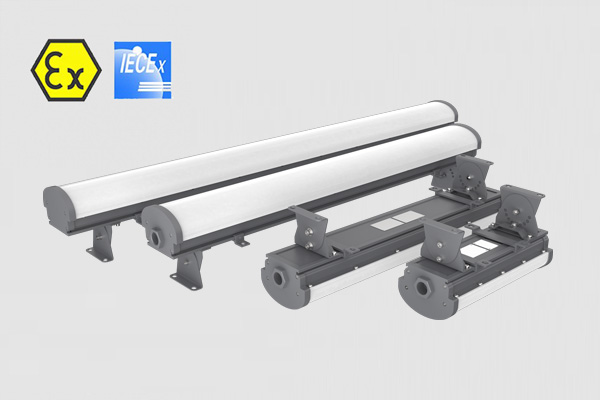

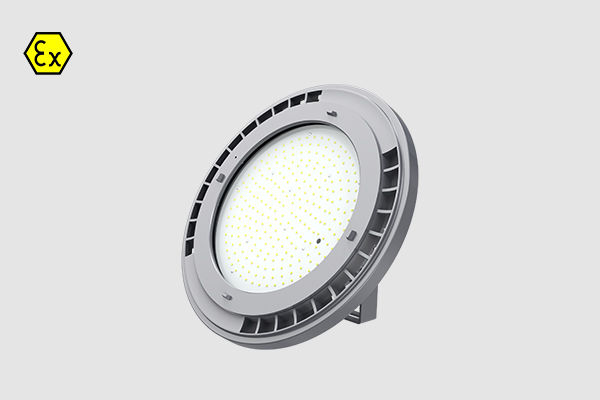

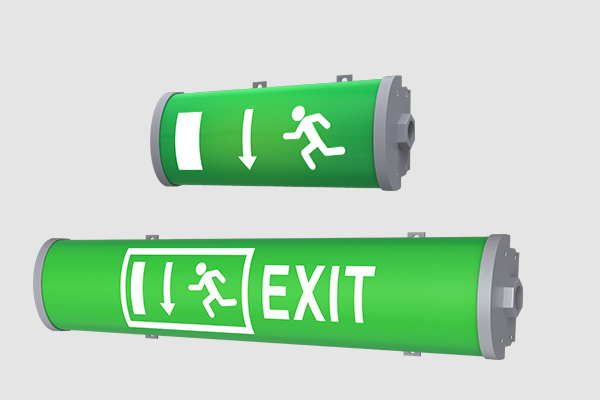

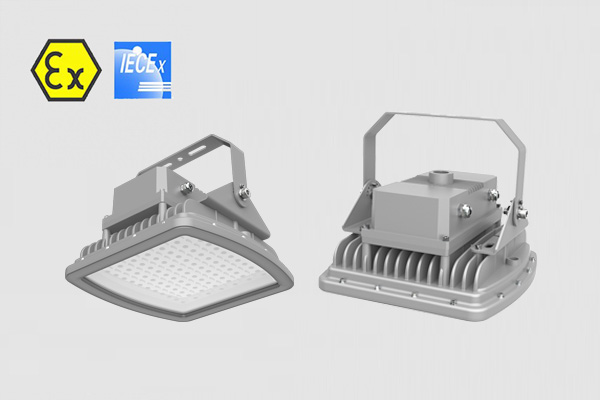

CESP explosion-proof linear lamp obtained ATEX/IECEx/UL certification, suitable for Zone1&21,Zone2&22 hazardous areas, can fully meet your advanced explosion-proof requirements. Die cast aluminum shell made of high technology core pulling system is used in the shell. At the same time, the engineer has carried out a special design to improve the heat dissipation effect and make the life of explosion-proof lamps longer, which can reach more than 50000 HRS. Linear explosion-proof light also uses high-quality LEDlm80 lamp beads, while saving energy and environmental protection, but also has strong light-effect lighting. Light reflection cup design, folding 120 degrees.

With the increase of cold storage demand, the requirements for safety are gradually increasing. CESP focuses on the research and development, manufacture and sale of high-quality military patented products, it is a famous manufacturer OEM/ODM explosion-proof lamps in China and a supplier of lighting solutions in hazardous areas.

Description:With the continuous development of the cold chain logistics industry, the number of users who need to build cold storage is increasing. Once anything develops too fast, all kinds of malpractice will gradually emerge. Only in this way can the normal use of cold storage and the personal safety of employees be guaranteed.

Compact 20 Watt Led Tube Lamps T8 Explosion Proof For Cold Storage Food Factory for sale, China LED Tri Proof Lights wholesaler, China LED Tri Proof Lights manufacturer, China LED Tri Proof Lights exporter, China LED Tri Proof Lights company认证