For Zone 1 Zone 2, Zone 21 Zone 22 hazardous area led lighting, 20W - 200W, 130lm/W,aluminum alloy + 8mm tempered glass, multi-installation for different projects, such as light tower, canopy light, marine grade.

Flameproof enclosure, Ex db op is IIC T6 Gb, Zone 1 & Zone 21 with explosive gas atmosphere, Zone 21 and Zone22 with explosive dust atmosphere, 10mm temered glass, 7J impact resistance,up to 26000lm.

Flameproof enclosure, Ex db op is IIC T6 Gb, IP68 protection grade, tempered glass 10mm, withstand impacts up to 10J, 2 foot and 4 foot Length, 50Watt- 240Watt, 130lm/W light efficacy.

Zone 1 & Zone 21, 1ft, 2ft, 3ft, 4ft length can be selected, replace the traditional explosion-proof three-proof lamp, explosion-proof fluorescent tube, anti-corrosion, anti-glare, anti-drop, competitive price.

Flameproof LED hand lamp for Zone 1 & Zone 21 hazardous areas, 10mm tempered glass, pass the multi-angle drop test, 10W, 20W, 30W Power, can be connected to the cable, emergency power box.

The CES-EX-SF series explosion-proof ceiling lamp has a strong shell, with features such as impact resistance, vibration resistance, and corrosion resistance. It can be used in hazardous environments of Zone 1&21, Zone 2&22.

CES-EX-JX Series is your go-to solution for illuminating hazardous Zone 1 and Zone 21 areas. With ATEX approval, these Explosion-proof LED Flood Lights offer unbeatable safety standards.

Discover the pinnacle of safety and illumination with our CES-EX-GBX Series Explosion-proof LED High Bay Lights. Designed for hazardous Zone 1 and Zone 21 areas, these lights boast ATEX approval, ensuring the highest safety standards.

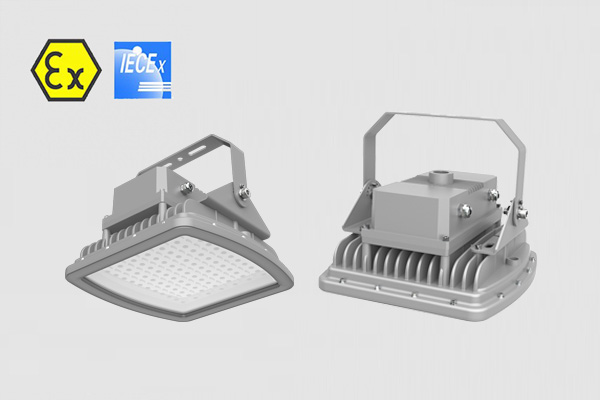

GB-02 explosion-proof lights are made of alloy aluminum and tempered glass, with shock resistance and anti-vibration performance. The luminaires have passed the ATEX IECEx standards test, from 30W to 80W for hazardous area lighting.

LN-02 explosion-proof lights obtained an IECEx ATEX certificate, it's safe for the Zone 1 and Zone 2 hazardous locations. The copper-free aluminum alloy body is powder-coated to increase durability and beautiful appearance, are able to withstand violent shaking and shock resistance.

an innovative line of LED hazardous area lighting products, specifically designed for use in potentially explosive atmospheres (Zone 1/21 & 2/22) within harsh industrial settings such as coal mines and oil & gas facilities.

Explosion-proof safety exit lamps are for personnel evacuation, and fire operations to provide lighting fire emergency lamps! It usually uses an external power supply, when the power automatically switches to the battery power state!

This project in the Thailand, a Ink plant, use 120W CESP LED explosion proof flood light, up to 13800 lumen flux, very perfect to replace the traditional lamp.

This project in the Thailand, a Ink plant, use 120W CESP LED explosion proof flood light, up to 13800 lumen flux, very perfect to replace the traditional lamp.

CESP LED Explosion Proof Light appliction in MT Gas Station, it was replace to the tradiional gas station light, high lumen high brightness, help to energy saving.

The coking plant is generally composed of a coal preparation plant, a coking plant, a recycling plant,

a tar processing plant, a benzene processing plant, a desulfurization plant, and a waste water treatment plant.

Coking plant basement, high temperature, average annual temperature of 20-25 °C, slight vibration, dust, but not strong, daily build sanitation, there will be dust flying phenomenon, to maintain lighting.

Metallurgical industry lighting solutions must consider reducing the safety issues in the metallurgical industry due to lighting in all regions and each worker safe, improve the productivity, and reduce the probability of accidents.

Delayed coking is the secondary processing of petroleum coke, gasoline, diesel oil, wax oil, and gas by thermal destruction of residual oil under high temperature conditions. The coking process is a comprehensive process of thermal decomposition and condensation. The device belongs to high temperature (up to a maximum temperature of 1000°C, medium temperature up to 500°C), high pressure (maximum pressure up to 3.8MPa), flammable and explosive devices. The raw materials used in the device are atmospheric and vacuum decompressed residual oils, the auto-ignition temperature is 230-240°C, and the operating temperature of the device is more than 300°C. Once the leakage is easy to occur, the dry gas produced and the boiling point and flash point of gasoline are produced. They are very low and can form explosive mixtures with air. Their explosion limits are 1.5% to 15% (V/V) and 1.4% to 7.6% (V/V), respectively. At the same time, because the autoignition point of diesel and wax oils of their products are all lower than the operating temperature of the device, fire is easily occurred and there is a great danger.

Leakage is a common cause of flammable (explosive) mixtures. Leakage of flammable gases, flammable liquids, and liquids whose temperature exceeds the flash point will produce a flammable (explosive) mixture in the leaked area or on the leaked liquid surface.

Many facilities of coking plants are equipped with discharge pipes, equipment for processing or storing flammable and flammable materials, or storage tanks. The gas (gas) bodies released by the discharge pipes are themselves flammable (explosive) mixtures, or they are released from the air. Mix into a combustible (explosive) mixture.

Therefore, coke plant as a CLASS I hazardous locanti, all fire and explosion protection measures are to prevent the production of flammable (explosive) mixtures or prevent the generation and isolation of sufficient strength of the activation energy, in order to avoid the ignition of combustible mixture combustion, explosion.

Therefore, coke plant as a CLASS I hazardous locanti, all fire and explosion protection measures are to prevent the production of flammable (explosive) mixtures or prevent the generation and isolation of sufficient strength of the activation energy, in order to avoid the ignition of combustible mixture combustion, explosion.

CESP LED Explosion-proof led flood lights and LED Explosion proof high bay lights special for Class I Div 1, Div 2, Class II Div 1, Div 2 hazardous lighting, can meet your high-level explosion-proof requirements.

The aviation base is an important national base. The rocket fuel plus liquid hydrogen and booster workshop is an area that..

absolutely needs to work in an explosion-proof environment, including anti-static electricity.

.jpg)

These places need a lot of explosion-proof products, including explosion-proof lighting, explosion-proof switches, and these products are also a high standard and strict requirements. Explosion-proof products in these places generally have international military standard requirements and ISO9001 series of guarantees, and even other special requirements.

.jpg)

The main production areas of the Oil Field United Station are pump rooms, valve rooms, metering rooms, drug-adding rooms, water injection rooms, and other areas. These areas are closed environments and there are long-term flammable and explosive gases.

All electrical appliances used must meet the explosion-proof requirements, and the production area has high lighting requirements. Traditional gas discharge lamps consume large amounts of electricity and suffer from severe light failure, which can easily cause insufficient on-site lighting and affect production operations.

.jpg)

In addition, in addition to the explosion-proof requirements for electrical appliances in the external area of the Oil Field United Station, the external lighting area is very large, the installation height of the lamps is high, the power is large, and the environment is in a wind and rain for a long time.

.jpg)

CESP explosion-proof infield lighting solutions can provide customers with energy-efficient LED lighting products, uniform illumination, low light attenuation, and long life, providing safe, green lighting services for explosion-proof in-field areas.

CESP explosion-proof field lighting solutions not only through professional lighting design, in the optical design, high luminous efficiency, light decay, uniform light, so that the best lighting effects in the field. Second, the use of lamps and lanterns also passed the international explosion-proof certification, shell protection are more th IP65. Long lifespan and long-term maintenance-free help to save cost.

The oil drilling offshore belongs to a special operating environment, which is significantly different from conventional lighting requirements. For example, in terms of uniformity of light distribution, color rendering index and color temperature of the light source, the requirements are not very strict.However, there are special requirements for the quality of lighting fixtures, vibration resistance, resistance to harsh environments, and explosion-proof safety. Recently, gas discharge light sources such as fluorescent lamps and metal halide lamps are mainly used for the lighting of oil drilling offshore. When this kind of light source is used as commercial and home lighting, it has incomparable superiority. However, when this type of light source is used in the petroleum cobalt drilling, its disadvantages are obvious, such as poor vibration resistance and poor low temperature resistance. Therefore, it is necessary to find a new type of light source to solve these problems from the light-emitting principle and lamp structure. LED technology is a kind of solid light source. Compared with traditional lamps, the explosion-proof lights developed and produced by it are fundamentally different in structure, electricity, light distribution and explosion-proof.

The lighting environment of the oil drilling offshore has its particularity, mainly including the following 4 points:

(1) Explosive. In case of fire, electric spark, high temperature and other ignition sources, it may cause combustion or even explosion. To ensure safety, the electrical appliances (including lighting fixtures) installed and used should be safe and explosion-proof.

(2) The vibration is large. During drilling, especially during relocation, the equipment vibrates greatly. Therefore, the electrical equipment installed and used should have good anti-vibration performance.

(3)High-risk, continuous operation, difficult to replace and maintain. Therefore, lighting fixtures should have a long life and less maintenance.

(4) The climatic conditions are harsh, so the lamps should have high environmental adaptability.

At present, most of the lamps for drilling lighting are fluorescent lamps or metal halide lamps. This kind of lamps has mature technology and comfortable vision. It is widely used in indoor and general lighting, and its disadvantages are obvious when used in the drilling environment.

① Poor vibration resistance and easy to damage. The equipment at the drilling is highly vibrating, especially during the relocation process. The lamp tubes made of glass are often damaged and need to be replaced in large quantities, resulting in a lot of manpower and material loss, and mercury vapor and broken glass are also causing the environment harm;

② There are many faults and maintenance is difficult, especially for high-risk equipment parts such as derricks. Once the lamps are damaged, they cannot be repaired in time, which will seriously affect the safety of night production;

③ The safety factor is low, especially for gas discharge lamps such as metal halide lamps. The temperature of the lamps is high during operation, which is likely to become a hidden danger of safety accidents;

④ The environmental adaptability is poor, and it often fails to work normally in a low temperature environment.

(1)LED light source

LED (Light Emitting Diode) is a kind of solid-state semiconductor device, which can directly convert electricity into light.

Since the discovery of the electroluminescence (LED) phenomenon in 1907, it has traveled more than 100 years. Since the 1990s, LED technology has continuously made breakthroughs. The technology in the fields of display, indication, and medium and large-size backlights has become increasingly mature. The field of application continues to expand. In the field of functional lighting, although LED technology is in its infancy, it is developing rapidly. At present, white LEDs with luminous efficiency above 120Lm/W have been mass-produced.It has become the fourth generation of electric light sources after incandescent lamps, fluorescent lamps, and high-pressure metal gas discharge lamps, and is called the ultimate form of electric light sources.

The LED, determined by the light-emitting principle, is the electric light source with the longest lifespan and the highest energy-saving benefit so far. It does not contain harmful substances, is environmentally friendly and has no pollution, is resistant to vibration, and has the advantages of shock resistance unmatched by other traditional light sources.

|

light source |

Principle of luminescence |

End of life |

|

Incandescent lamp |

When the electric current passes through the spiral tungsten filament in the incandescent lamp, a thermal effect occurs, so that the incandescent lamp radiates visible light and infrared light. |

The evaporation loss of the tungsten filament causes the filament to fuse. |

|

Fluorescent lamp |

The ballast supplies pulse voltage to preheat the filament and activate the electron emission material on the filament (cathode). The electrons collide with the mercury atoms inside the tube to generate ultraviolet light, and the ultraviolet light is refracted by the phosphor coated on the tube wall to reflect the visible light. |

The emitting material on the electrode is exhausted and can no longer emit electrons. |

|

High-intensity gas discharge lamp |

The collision of electrons, atoms, and ions in the discharge tube. |

The emission material is exhausted, so that the arc cannot be triggered. |

|

LED |

The recombination of electrons and holes in the PN junction emits light. |

The light attenuation is too large, or the PN junction is broken down. |

|

light source |

|

End of life |

LED lighting

LED lighting is another revolution in lighting sources after incandescent lamps and fluorescent lamps. It is recognized by all countries as the most promising high-efficiency lighting industry. At present, as a new generation of light source technology, LED is being widely recognized and recognized by people. More and more LED lighting products appear in roads, squares, vehicles, docks and urban landscapes. In some places, there are high requirements for energy saving and longevity. Inconvenient uninterrupted lighting places, such as tunnels, underground parking lots, etc., LED has obvious advantages and significant benefits.

The explosion-proof lamps developed and produced with LED light sources have the following special advantages when applied to drilling offshore lighting.

(1)Excellent safety and explosion-proof performance. LEDs driven by DC low voltage (≤36V), due to high luminous efficiency and low heat generation, operate under safe voltage and low temperature (T6≤85℃), which not only improves the explosion-proof performance of the lamp itself, but also reduces it from the source Accidents caused by lamps have improved the safety protection level of the drilling offshore.

Due to the low power of LED lamps and low input current, the tendency of cable overheating and aging is reduced and the safety of power supply lines is improved.

(2) Excellent anti-vibration performance. LED is a solid-state light source, and its excellent anti-vibration and impact resistance are unmatched by any traditional light source. It is used for drilling lighting to fundamentally overcome the disadvantages of vibration intolerance and extremely easy damage caused by the glass lamp tube, which can save manpower and material resources, reduce maintenance costs, and reduce environmental hazards.

(3) Long service life. LED directly converts electricity into light, and there is no mechanical damage when working. The effective life of the light source can reach 50000-100000 hours. It is the electric light source with the longest service life so far, which will greatly reduce the frequency of maintenance of lamps and lanterns and play a positive role in guaranteeing production.

(4) Super strong environmental adaptability. The low temperature resistance of LED is much better than that of traditional light sources. After necessary treatment, it can be lit and work normally in the environment of -45℃ and below. This provides an effective solution to the problem of wellsite lighting under low temperature conditions.

(5) High efficiency and energy saving. Compared with traditional light sources, LED energy-saving is more than 60%, and its use in drilling lighting means saving expensive fuel. For the increasingly popular grid-powered drilling, the energy-saving benefits are more direct and significant. Used for emergency lighting, the battery with the same capacity can extend the lighting time exponentially due to its high efficiency (without circuit inverter).

(2)Power supply

① Using constant current drive, the output current stability accuracy is ≤±25%;

② Used for explosion-proof power supply output voltage ≤ DC 36V;

③ Wide voltage and wide frequency input, adapt to the power requirements of different countries and regions;

④ Power factor ≥90%;

⑤ There should be short circuit, overvoltage, and overheat protection inside the power supply.

(3)Lamp material and structure

(4)Protection and explosion-proof performance

① The protection level of outdoor lamps should not be less than IP65;

② Anti-corrosion performance: indoor lamps should not be lower than F1, outdoor lamps should not be lower than WF1;

③ Explosion-proof performance The performance of explosion-proof LED lamps should meet the requirements of GB3836-2010《Explosive Environment》and pass the inspection of the national authority.

(5)Low temperature lights

It shall meet the requirements specified in GE/T 2423.1-2008《Environmental Testing of Electrical and Electronic Products Part 2: Test Method Test A: Low Temperature》, and pass the inspection by the national authority.

①The emergency time is not less than 60min;

②Emergency response time≤1s;

③The number of battery charging and discharging cycles is ≥500 times;

④Equipped with photosensitive control switch and working status indicator.

When choosing and using LED explosion-proof lamps, you need to pay attention to the following two aspects.

(1) Under the current conditions, LEDs from internationally renowned brands should be used to ensure the reliability of the quality of the lamps and the comfort of the lighting.

(2) Ensure a good heat dissipation system. As LED is a semiconductor component, the temperature of the chip directly affects its life during operation, so the heat dissipation of the lamp should be fully considered when using it.

CESP is a state-level high-tech enterprise and a contract energy management company that has been filed by the three ministries and commissions. CESP strive to high quality patent product in military & industry areas, is the Top OEM & ODM supplier for explosion proof lighting solution of China and the 1st Company in China to be certify for hazardous location led lighting fixture by UL & CUL. In December 2020, CSA Group issued UL844 and CSA 137 standard explosion proof certificate (Division 1) for CES-SC series, that means that CESP has made another big progress in the field of explosion-proof lighting.

CES-EX-GB-02 Was Designed In 2019 And Obtained UL Certification. It Can Be Used In Hazardous Environments Such As Class I, Division 2, Groups A, B, C And D; Class II, Division 2, Groups F And G; Class III Under Use.

Explosion Proof Led High Bay Lamp Body Is Made Of ADC12 Aluminum Alloy. The Industrial Designer Designs The Lamp Body Heat Dissipation Structure, Which Has A Sufficient Heat Dissipation Area. At The Same Time, The Lamp Body Is Coated And Colored, Which Not Only Improves The Durability And Makes The Lamp More Beautiful. The Shell Glass Adopts High-Strength Tempered Glass, Which Has Been Tested By Internal Pressure And Hydraulic Pressure. The Anti-Corrosion Grade Is WF2. The Power Supply Adopts The Well-Known Brand MEAN WELL HLG Series Power Supply. The Voltage Is In The International Common AC Input Range (Up To 305VAC, Efficiency Can Be As High As 94%, And Conforms To The World Lighting Equipment Safety Specification, IP Grade Is IP67, Can Withstand 4J Pressure, Indoor And Outdoor Installation Can Be Used, Can Be Applied To 40°C ~ 40/45/50°C Dry/Moisture/Rain Environment, And CESP Promises 5-Year Shelf Life. The Explosion Proof Light Beads Use High-Quality LM80 Certified Chips, And The Luminous Efficiency Is As High As 142LM\W. For Example, A 30W Explosion-Proof LED Work Light Can Produce 3600LM And A 115° Beam Angle. In General, The LED Explosion-Proof Patio Light Is Beautiful In Appearance, Simple And Convenient To Operate, And Can Be Installed In Ceiling, Pole-Mounted, Wall-Mounted Lighting And Other Methods, With High Structural Strength. It Is Suitable For General Area Lighting In Wastewater Treatment, Oil And Gas Refineries, Drilling Rigs, Petrochemical Facilities, Food And Beverage Facilities, Tunnels, Outdoor Wall And Stanchion Mounted General Area Lighting, And Where Flammable Vapors, Gases, Ignitable Dusts, Fibers Or Flyings Are Present.

If you want to know more details of this lamp, you can click here to view it. The following are some simple parameters of Ex-proof High bay light.

|

Model |

Power (W) |

Input voltage: AC100-277V; Frequency: 50/60Hz; |

|||||

|

CCT:3000K~6500K |

|||||||

|

Power factor:0.97 |

|||||||

|

Luminous flux (LM) |

Light efficiency (Lm/W) |

LEDs Chip |

LEDs Type (3V) |

Power Model |

Weights (kg) |

||

|

CES-EX-GB-02-30 |

30 |

3600 |

120 |

84PCS |

2835 |

HBG-60-1400P |

3.0/3.6 |

|

CES-EX-GB-02-40 |

40 |

4800 |

120 |

84PCS |

2835 |

||

|

CES-EX-GB-02-60 |

60 |

7200 |

120 |

120Pcs |

2835 |

HBG-100P-36A |

7.0/8.2 |

|

CES-EX-GB-02-80 |

80 |

9600 |

120 |

120Pcs |

2835 |

||

|

CES-EX-GB-02-100 |

100 |

12000 |

120 |

252Pcs |

2835 |

HLG-185H-36A |

14.3 |

|

CES-EX-GB-02-120 |

120 |

14400 |

120 |

252Pcs |

2835 |

||

|

CES-EX-GB-02-150 |

150 |

18000 |

120 |

252Pcs |

2835 |

||

|

CES-EX-GB-02-185 |

185 |

22200 |

120 |

252Pcs |

2835 |

||

|

CES-EX-GB-02-200 |

200 |

24000 |

120 |

252Pcs |

2835 |

||

If you want to know more details of this lamp, you can click here to view it. The following are some simple parameters of Ex-proof High bay light. Offshore drilling platforms are important production bases for petroleum products and natural gas. The main component of natural gas is methane. People and equipment are transported by helicopters in these off-shore offshore market bases. The concentration of oil and gas generated during drilling is constantly changing. These locations must use CLASS I explosion-proof products. Similarly, in factories that use these oil and gas products as raw materials, for example, chemical plants that use pentane to further chemically react with ether groups, chemical fertilizer factories, and so on, all need to work under safe and non-hazardous conditions. These places must be absolutely flame retardant. Explosion-proof lamps and other explosion-proof switchgear equipment developed by CESP are dedicated to these CLASS I hazardous environments.

The gas station is a highly standardized place. Because of the explosion hazard and toxicity of motor fuel,

it is not easy to control the gas station in case of accident, and the gas station has many points, so the safe operation of the gas station greatly affects the people. The safety of life and property.

The gas station is a highly standardized place. Because of the explosion hazard and toxicity of motor fuel,

The gas station is a highly standardized place. Because of the explosion hazard and toxicity of motor fuel, it is not easy to control the gas station in case of accident, and the gas station has many points, so the safe operation of the gas station greatly affects the people. The safety of life and property.

In nowadays, the lamps commonly used in regulated gas stations are led explosion-proof light. The level of the luminaires should reach the basic explosion-proof level, and the EX explosion-proof mark can be clearly seen on the lamp housing.

Lighting fixtures outside the explosion hazardours area of the refueling station can be of non-explosion-proof light. but luminaires in non-explosive hazardous areas under the awning, lighting fixtures with a degree of protection not less than IP44 should be used.

Of course, different countries have different standards, and according to relevant standards, select explosion-proof lamps that require high requirements.

In addition, the task of gas station lighting design is to first establish a customer's sense of security and trust to attract customers, and secondly, a happy consumer experience will ensure that customers come again. Good customer service begins when the customer enters the gas station, and comfort is the first element of pleasing the customer. The general illumination is greater than 100 lx. But, CESP design recommendation is higher than 300 lx.