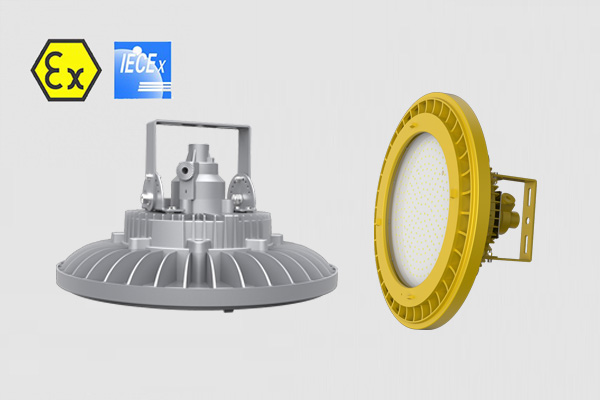

IECEx ATEX Certified Explosion proof LED Lights - Zone 1 Zone 2 Hazardous Area Lighting

For Zone 1 Zone 2, Zone 21 Zone 22 hazardous area led lighting, 20W - 200W, 130lm/W,aluminum alloy + 8mm tempered glass, multi-installation for different projects, such as light tower, canopy light, marine grade.

Flameproof enclosure, Ex db op is IIC T6 Gb, Zone 1 & Zone 21 with explosive gas atmosphere, Zone 21 and Zone22 with explosive dust atmosphere, 10mm temered glass, 7J impact resistance,up to 26000lm.

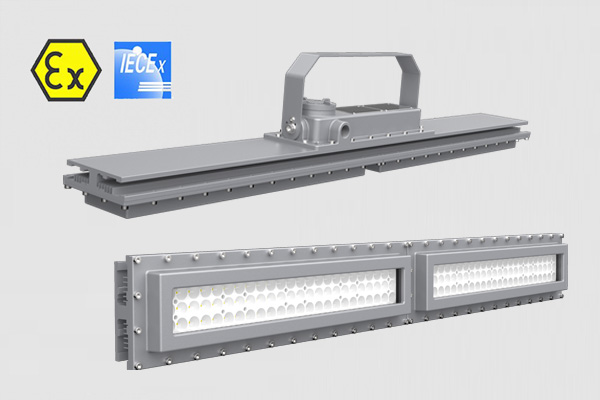

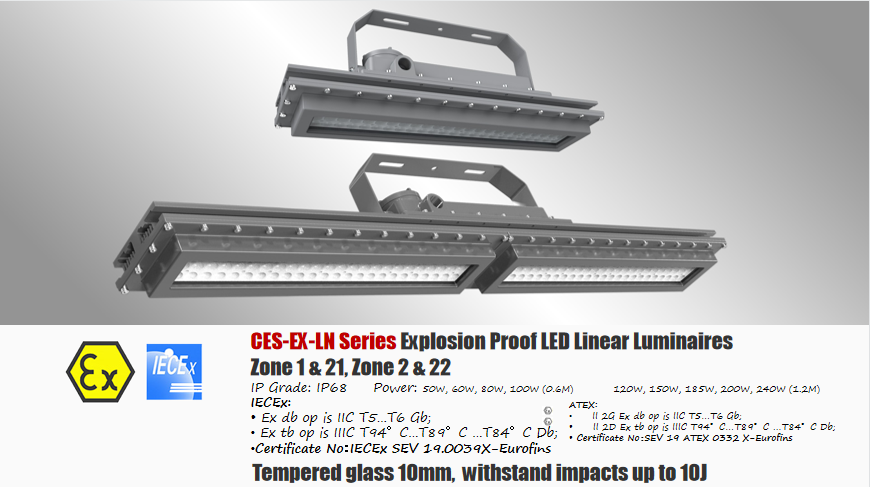

Flameproof enclosure, Ex db op is IIC T6 Gb, IP68 protection grade, tempered glass 10mm, withstand impacts up to 10J, 2 foot and 4 foot Length, 50Watt- 240Watt, 130lm/W light efficacy.

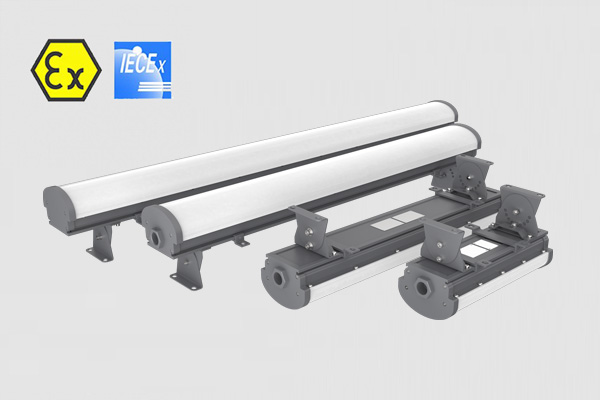

Zone 1 & Zone 21, 1ft, 2ft, 3ft, 4ft length can be selected, replace the traditional explosion-proof three-proof lamp, explosion-proof fluorescent tube, anti-corrosion, anti-glare, anti-drop, competitive price.

Flameproof LED hand lamp for Zone 1 & Zone 21 hazardous areas, 10mm tempered glass, pass the multi-angle drop test, 10W, 20W, 30W Power, can be connected to the cable, emergency power box.

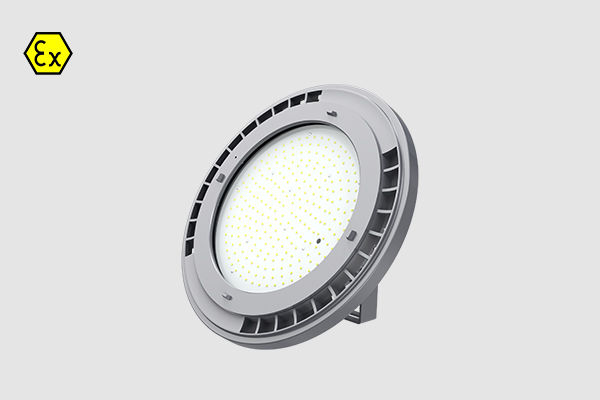

The CES-EX-SF series explosion-proof ceiling lamp has a strong shell, with features such as impact resistance, vibration resistance, and corrosion resistance. It can be used in hazardous environments of Zone 1&21, Zone 2&22.

CES-EX-JX Series is your go-to solution for illuminating hazardous Zone 1 and Zone 21 areas. With ATEX approval, these Explosion-proof LED Flood Lights offer unbeatable safety standards.

Discover the pinnacle of safety and illumination with our CES-EX-GBX Series Explosion-proof LED High Bay Lights. Designed for hazardous Zone 1 and Zone 21 areas, these lights boast ATEX approval, ensuring the highest safety standards.

GB-02 explosion-proof lights are made of alloy aluminum and tempered glass, with shock resistance and anti-vibration performance. The luminaires have passed the ATEX IECEx standards test, from 30W to 80W for hazardous area lighting.

LN-02 explosion-proof lights obtained an IECEx ATEX certificate, it's safe for the Zone 1 and Zone 2 hazardous locations. The copper-free aluminum alloy body is powder-coated to increase durability and beautiful appearance, are able to withstand violent shaking and shock resistance.

an innovative line of LED hazardous area lighting products, specifically designed for use in potentially explosive atmospheres (Zone 1/21 & 2/22) within harsh industrial settings such as coal mines and oil & gas facilities.

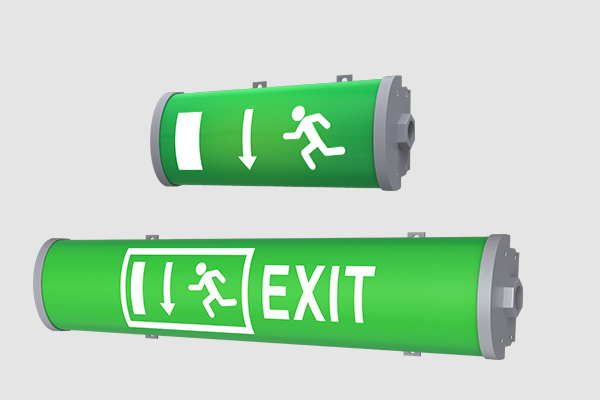

Explosion-proof safety exit lamps are for personnel evacuation, and fire operations to provide lighting fire emergency lamps! It usually uses an external power supply, when the power automatically switches to the battery power state!

Food Grade LED High Bay (NFS) CES-HB6

UFO LED High Bay Light Fixture CES-HB5

UFO LED High Bay CES-HB4

UFO LED High Bay Light CES-HB3

UFO LED High Bay Lighting CES-HB2

UFO LED High Bay CES-HB1

petrochemical enterprises Lighting solutions

- Characteristics and needs of petrochemical enterprises

Since the 21st century, especially in recent years, petrochemical companies have gradually appeared in people's vision, and people's thinking has gradually changed and more and more attention has been paid to sustainable development. All areas of society are constantly developing and progressing, and the production of petrochemical industry is a high-risk industry. Once a fire or explosion accident occurs, it will often cause greater casualties or property losses. From a safety perspective, petrochemical companies are different from industries such as metallurgy, machinery manufacturing, infrastructure, textiles, and transportation. The materials of petrochemical enterprises are dangerous, as are the processes and media. Their safety characteristics determine higher requirements for petrochemical enterprises. For petrochemical companies, lighting is also a very important link.

- Standard value of lighting for petrochemical equipment

|

Site name |

Reference plane And its height |

Horizontal illuminance Standard value/lx |

Horizontal illuminance Evenness |

UGR |

Ra |

|

|

Give birth Produce Attire Set Area |

Pump area, valve, main pipe under pipe rack |

Ground |

50 |

0.4 |

— |

20 |

|

Control panel, operation station |

Working surface |

150 |

0.4 |

— |

20 |

|

|

Heat exchanger |

On the plane |

30 |

0.25 |

— |

20 |

|

|

General platform |

On the plane |

10 |

0.25 |

— |

20 |

|

|

Operating platform |

On the plane |

s0 |

0.4 |

— |

20 |

|

|

cooling tower |

Ground |

30 |

0.25 |

— |

20 |

|

|

General ladders, stairs |

On the plane |

10 |

0.25 |

— |

20 |

|

|

Commonly used ladders and stairs |

On the plane |

50 |

0.4 |

— |

20 |

|

|

Indicating dial |

Working surface |

50 |

0.4 |

— |

60 |

|

|

Instrumentation |

Working surface |

50 |

0.4 |

— |

20 |

|

|

Compressor plant |

On the plane |

100 |

0.4 |

— |

20 |

|

|

Industrial furnace |

On the plane |

30 |

0.4 |

— |

20 |

|

|

splitter |

Dam crest |

50 |

0.4 |

— |

20 |

|

|

General area |

Ground |

10 |

0.25 |

— |

20 |

|

|

Electric stove |

Ground |

50 |

0.25 |

— |

20 |

|

|

Conveyor belt |

On the plane |

20 |

0.25 |

— |

20 |

|

|

Transfer point |

On the plane |

50 |

0.25 |

— |

20 |

|

|

Extrusion mixer |

On the plane |

200 |

0.25 |

— |

20 |

|

|

Air separation air compressor |

Ground |

50 |

0.4 |

— |

20 |

|

|

Site name |

Reference plane And its height |

Horizontal illuminance Standard value/lx |

Horizontal illuminance Evenness |

UGR |

Ra |

||

|

Non Give birth Produce Attire Set Area |

Tank farm |

General area |

Ground |

10 |

0.25 |

— |

20 |

|

Climbing ladders, stairs |

On the plane |

5 |

— |

— |

20 |

||

|

Monitoring area |

Ground |

10 |

0.25 |

— |

20 |

||

|

Into the hole |

On the plane |

5 |

— |

— |

20 |

||

|

Circulating water field |

Ground |

10 |

0.25 |

— |

20 |

||

|

Sewage treatment plant |

Ground |

10 |

0.25 |

— |

20 |

||

|

Wastewater tank, rainwater |

Ground |

10 |

0.25 |

— |

20 |

||

|

General area |

Ground |

50 |

0.25 |

— |

20 |

||

|

Tank trucks, loading and unloading points |

Working surface |

100 |

0.4 |

— |

20 |

||

|

main road |

Ground |

10 |

0.4 |

— |

20 |

||

|

Secondary road |

Ground |

5 |

0.25 |

— |

20 |

||

|

Building |

Change Electricity |

Outdoor power distribution device |

Working surface |

20 |

0.4 |

— |

|

|

Indoor power distribution device |

0.75m horizontal plane |

200 |

0.5 |

— |

80 |

||

|

Cable room |

Ground |

50 |

0.4 |

— |

60 |

||

|

Electrical control room |

0.75m horizontal plane |

300 |

0.5 |

22 |

80 |

||

|

Transformer room |

Oil pillow |

50 |

0.4 |

20 |

|||

|

Control room |

General control room |

0.75m horizontal plane |

300 |

0.5 |

22 |

80 |

|

|

Instrument cabinet |

1.5m horizontal plane |

300 |

0.5 |

— |

80 |

||

|

Back of the cabinet |

1.5m horizontal plane |

100 |

0.5 |

— |

80 |

||

|

Engineer station |

0.75m horizontal plane |

300 |

0.5 |

22 |

80 |

||

|

Central control room |

5.75m horizontal plane |

500 |

0.6 |

19 |

80 |

||

|

Instrument cabinet |

1.5m horizontal plane |

500 |

0.6 |

— |

80 |

||

|

Back of the cabinet |

1.5m horizontal plane |

100 |

0.6 |

— |

80 |

||

|

Engineer station |

0.75m horizontal plane |

500 |

0.6 |

19 |

80 |

||

|

Analysis Laboratory |

Research, laboratory |

0.75m horizontal plane |

500 |

0.6 |

22 |

80 |

|

|

General analysis room |

0.75m horizontal plane |

300 |

0.6 |

22 |

80 |

||

|

Office building |

Continuous complex workplace |

0.75m horizontal plane |

1000 |

0.6 |

19 |

80 |

|

|

Complex workplace (accounting, statistics, etc.) |

0.75m horizontal plane |

750 |

0.6 |

19 |

8o |

||

|

General office |

0.75m horizontal plane |

500 |

0.6 |

22 |

80 |

||

|

Reception rooms, stairs, corridors, aisles |

Ground |

50 |

0.4 |

25 |

60 |

||

|

Hall |

Ground |

100 |

0.4 |

— |

60 |

||

|

Toilet, bathroom |

Ground |

75 |

0.4 |

— |

60 |

||

|

Electromechanical Repair |

Equipment maintenance room General area |

Ground, |

150 |

— 0.6 |

— 25 |

80 60 |

|

|

Warehouse |

1.0m horizontal plane |

100 |

0.6 |

— |

60 |

||

|

Other |

Trestle |

Bridge deck |

10 |

0.4 |

— |

||

- Selection and installation of lighting fixtures

- The selection and installation of lighting fixtures should ensure safety under normal conditions, and should not cause danger to people and the environment.

- High-efficiency lamps should be selected to meet the glare restrictions and light distribution requirements

- The selection of lamps should comply with the following principles:

- In general outdoor venues, the protection level should not be lower than IP54;

- Outdoor covered venues; the protection level should not be lower than IP44;

- When the environmental pollution is serious; the protection level should not be lower than IP65;

- Anti-corrosion: Corrosive environment should use lamps with corresponding anti-corrosion grade;

- Anti-vibration: Lamps and lanterns used in a vibrating and swinging environment should have anti-vibration and anti-falling measures;

- Dustproof: lamps used in explosive gas, dust or fire hazard areas.

CESP high-quality explosion-proof led lights can be used in Zone 1 and Zone 21, Class I Class 1 and Class 2, and Class II Class 1 and Class 2 hazardous locations. They are very suitable for lighting in pharmaceutical factories.

|

Lamp type |

Lamp picture |

Application area |

|

This explosion proof led floodlight adopts a sealed structure design, waterproof grade IP66, anti-corrosion grade WF2, and meets UL1598A marine grade certification, And it has stronger anti-vibration and impact resistance, and can be used in hazardous areas where combustible or explosive substances may exist in the normal environment. |

||

|

This explosion-proof patio lamp is equipped with a corrosion-resistant high-strength aluminum alloy shell, IP66 waterproof rating and WF2 anti-corrosion rating, which is very suitable for salt water and corrosive environments. The anti-shock and vibration pattern tempered glass lampshade design can reduce glare, and is suitable for use in hazardous environments where combustible or explosive substances are continuously or frequently present in normal environments. |

||

|

|

This explosion proof led drop light is durable and corrosion-resistant. It has undergone extreme water pressure and heavy pressure tests and can withstand 7J pressure and 3M underwater operations. The IP66 waterproof rating and the WF2 anti-corrosion rating enable the portable hand lamp with vibration resistance and impact resistance to be used as inspection lights and explosion-proof work lights in dangerous areas where flammable or explosive substances may exist in the normal environment. |

Cigarette factory lighting solutions

Lighting design should fully consider the characteristics of continuity, automation, high speed, high taxes and benefits of cigarette production, as well as local dusty, humid, and high-temperature environmental conditions to ensure reliable lighting and good vision, pay attention to safety protection, and prevent electric shock and electrical Fire etc.

- The choice of lighting method

- According to the various layout and use requirements of the craft, under the principle of satisfying the visual requirements and energy saving, the general lighting partitions, general lighting or mixed lighting, etc. shall be used respectively, but the local lighting shall not be used alone.

- The lighting methods used in major production sites are as follows:

- General lighting should be adopted in the rolling package and filter rod forming workshop; when the lamps are arranged along the production line and the installation and commissioning are low, the general lighting of the partition is declared.

- Divisional general lighting should be adopted in the workshops of threshing and redrying, silk making, tobacco flakes, and tobacco expansion.

- Some areas of the leaf threshing and redrying and silk making workshops, such as the leaf distribution table, the leaf selection table, the exit of the cutting machine, and the exit of the drying machine, should adopt mixed lighting.

- Lighting standard value (Friendly reminder: this standard value is for reference only)

Standard value of illuminance of working surface in production and workplace

|

Production and workplace |

Standard value of illumination (1x) |

Note |

||

|

primary |

intermediate |

advanced |

||

|

Tobacco grading and batching room |

100 |

150 |

200 |

|

|

Threshing and redrying workshop |

100 |

150 |

200 |

|

|

Vacuum regaining section |

100 |

150 |

200 |

|

|

Point-cutting section |

100 |

150 |

200 |

|

|

Leaf base and tip selection section |

100 |

150 |

200 |

|

|

Leaf base and tip selection table |

150 |

200 |

300 |

|

|

Leaf and stem separation section |

100 |

150 |

200 |

|

|

Leaf redrying section, tobacco stem redrying section |

100 |

150 |

200 |

|

|

Blade packing section, tobacco stem packing section, broken leaf processing section |

100 100 |

150 150 |

200 200 |

|

|

Dust removal room |

30 |

50 |

75 |

|

|

Workshop sample room |

150 |

200 |

300 |

|

|

Packing material room |

30 |

50 |

75 |

|

|

Online control panel |

75 |

100 |

100 |

Screen vertical |

|

Silk workshop |

100 |

150 |

200 |

|

|

On-line control panel for the outlet of shredder (cut leaf shreds, cut stem shreds), silk dryer, and shredder shredder export |

150 75 |

200 100 |

300 150 |

Screen vertical |

|

Leaf storage cabinet, stem storage cabinet |

50 |

75 |

100 |

|

|

Wire storage cabinet, stalk storage cabinet |

50 |

75 |

100 |

|

|

Spice and sugar preparation room |

100 |

150 |

200 |

|

|

Dust removal, smoke and dust treatment room |

30 |

50 |

75 |

|

|

Rolling and wrapping workshop |

75 |

100 |

150 |

|

|

Roll-up package, packing section |

150 |

200 |

300 |

If it is a windowless factory, the illuminance will be increased by one level |

|

Finished product conveying corridor |

30 |

50 |

75 |

|

|

Cigarette temporary storage room |

50 |

75 |

100 |

|

|

Temporary storage room for auxiliary materials |

50 |

75 |

100 |

|

|

Finished product turnover warehouse |

50 |

75 |

100 |

|

|

Residual smoke treatment room |

75 |

100 |

150 |

|

|

Glue room |

75 |

100 |

150 |

|

|

Dust removal, smoke and dust treatment room |

30 |

50 |

75 |

|

|

Vacuum pump room |

30 |

50 |

75 |

|

|

Auxiliary room of threshing and redrying, silk making, and wrapping workshop |

||||

|

Workshop inspection room |

150 |

200 |

300 |

|

|

Workshop control room |

100 |

150 |

200 |

|

|

Mechanical and electrical maintenance room |

300 |

500 |

750 |

|

|

Spare parts room |

30 |

50 |

75 |

|

|

Forklift charging room |

30 |

50 |

75 |

|

|

Lubricant Room |

20 |

30 |

50 |

|

|

Filter rod forming workshop |

||||

|

Temporary storage room for tow and auxiliary materials |

50 |

75 |

100 |

|

|

Filter rod forming and launching section |

100 |

150 |

200 |

|

|

Triacetin temporary storage room |

30 |

50 |

75 |

|

|

Tobacco sheet workshop |

||||

|

Forming section |

100 |

150 |

200 |

|

|

Flake and flake wire storage room |

100 |

150 |

200 |

|

|

Tobacco expansion workshop |

100 |

150 |

200 |

|

|

Dry ice method tobacco expansion section |

100 |

150 |

200 |

|

|

Carbon dioxide storage room |

30 |

50 |

75 |

|

|

Quality control room |

100 |

150 |

200 |

|

|

Central control room |

100 |

150 |

200 |

|

|

Near looser |

150 |

200 |

300 |

|

|

Hot and cold end control panel |

75 |

100 |

150 |

Screen vertical |

|

Pump House |

30 |

50 |

75 |

|

|

Freon method tobacco expansion room |

100 |

150 |

200 |

|

|

Puffing treatment room |

100 |

150 |

200 |

|

|

Expanded tobacco storage room |

30 |

50 |

75 |

|

|

Central laboratory and tobacco testing station |

||||

|

Laboratory |

150 |

200 |

300 |

|

|

Cigarette Evaluation Room |

150 |

200 |

300 |

|

|

Auxiliary room |

75 |

100 |

150 |

|

|

storehouse |

||||

|

Original Tobacco Bank |

20 |

30 |

50 |

|

|

Finished product library |

30 |

50 |

75 |

|

|

Finished product turnover warehouse |

30 |

50 |

75 |

|

|

Tobacco Bank |

30 |

50 |

75 |

|

|

Tobacco turnover bank |

30 |

50 |

75 |

|

|

Tow library |

30 |

50 |

75 |

|

|

Paper Material Library |

30 |

50 |

75 |

|

|

Hardware spare parts library |

30 |

50 |

75 |

|

|

Flammable goods warehouse |

20 |

30 |

50 |

|

|

Scrap library |

20 |

30 |

50 |

|

|

Liquefied Petroleum Gas Storage |

20 |

30 |

50 |

|

|

Diesel depot |

20 |

30 |

50 |

|

Standard value of illuminance in auxiliary room

|

Room name |

Height of working surface from ground (m) |

Standard value of illuminance (1x) |

Note |

||

|

primary |

intermediate |

advanced |

|||

|

Office, data room, accounting room, file room, reception room |

0.75 |

100 |

150 |

200 |

|

|

Design room, drawing room, craft room |

0.75 |

150 |

200 |

300 |

|

|

Product showroom |

0.75 |

150 |

200 |

300 |

|

|

Reading room |

0.75 |

100 |

150 |

200 |

|

|

Typing room |

0.75 |

150 |

200 |

300 |

|

|

Binding room, copy room, printing room |

0.75 |

75 |

100 |

150 |

|

|

Infirmary |

0.75 |

75 |

100 |

150 |

|

|

Workshop lounge |

ground |

50 |

75 |

100 |

|

|

Canteen |

0.75 |

50 |

75 |

100 |

|

|

kitchen |

0.75 |

75 |

100 |

150 |

|

|

Bathroom, changing room |

ground |

20 |

30 |

50 |

|

|

Toilet |

ground |

10 |

15 |

20 |

|

|

bathroom |

0.75 |

20 |

30 |

50 |

|

|

hall |

ground |

30 |

50 |

75 |

|

|

Corridor, stairwell |

ground |

15 |

20 |

30 |

|

Standard value of illuminance in open spaces and roads

|

Place name |

Determine the plane of illuminance |

Standard value of illuminance (1x) |

Note |

|||

|

Open space |

Tobacco yard |

ground |

2 |

3 |

5 |

|

|

Coal yard |

ground |

0.5 |

1 |

2 |

||

|

cooling tower |

Water tower platform |

2 |

3 |

5 |

||

|

Factory front area |

ground |

10 |

15 |

20 |

||

|

Factory road |

Main road |

ground |

3 |

5 |

10 |

|

|

Secondary road |

ground |

1 |

2 |

3 |

||

- Lighting requirements for cigarette factories

The system layout of the cigarette factory is more complicated. Therefore, in its lighting design, first determine the choice of lamps of a certain model and power, then reasonably determine the arrangement of lamps and lanterns and lamps number.

Lamp selection:

- Flameproof lamp

- Waterproof and dustproof lamps

- Anticorrosive lamps

- Shock-resistant and impact-resistant lamps

Application of CESP LED explosion-proof lighting in cigarette factories:

CESP high-quality explosion-proof led lamps can be used in Zone 1 and Zone 21, Class I Class 1 and Class 2, and Class II Class 1 and Class 2 hazardous locations. They are very suitable for lighting At the cigarette factory.

|

Lamp type |

Lamp picture |

Application area |

|

Trestle roads, on-site roads, unloading dockes, loading docks, etc. |

||

|

Storage yard, belt conveyor corridor, transfer building, shipping dock, etc. |

||

|

|

Such as oil refineries, offshore production, drilling platforms, fuel depots, chemical plants, cigarette factories |

coal washing plants lighting solution

Coal washing is an indispensable process in coal deep processing. The coal mined directly from the mine is called raw coal.The raw coal is mixed with many impurities in the mining process, and the quality of coal is different. Coal with a low intrinsic ash content and coal with a high intrinsic ash content will mix. Coal washing is an industrial technique that removes impurities from raw coal, or classifies high-quality coal from inferior coal.

The products produced after the coal washing process are generally divided into gangue, medium coal, grade B clean coal, and grade A clean coal. The finished coal after the coal washing process is usually called clean coal. Coal washing can reduce the cost of coal transportation and increase the utilization rate of coal. Cleaning coal is generally an energy source that can be used as fuel. Cleaning coal is generally used for coking, which needs to remove sulfur and impurities in industrial processes to meet the standards for coking.

The purpose of removing gangue in coal is to prevent it from melting and forming agglomerates during high-temperature combustion, which can easily block the furnace or other combustion facilities, and it does not burn to reduce the heat of combustion and affect efficiency.

Selection and arrangement of explosion-proof lighting fixtures

The system layout of the coal preparation plant is relatively complicated, and the architectural design such as screening and crushing, the main plant, and the belt conveyor trestle have their own characteristics. Therefore, in its lighting design, it is first necessary to determine the selection of lamps of a certain model and power, and then reasonably determine the arrangement of lamps and the number of lamps.

- Flameproof enclosure type: The raw coal system should use LED explosion-proof lamps.

- Waterproof and dustproof type: Waterproof and dustproof lamps should be used in other workshops.

- Anti-corrosion type: It is necessary to specify that the flotation reagent storehouse should be selected anticorrosive lamps.

- Shock-proof and anti-falling: Shock-proof lamps should be used in places with heavy vibrations such as forging hammers and large bridge cranes, and anti-falling measures should be taken for lamps used in places with large swings.

CESP LED explosion-proof lighting application in coal mine:

CESP high-quality explosion-proof led lamps can be used in Zone 1 and Zone 21, Class I Class 1 and Class 2, and Class II Class 1 and Class 2 hazardous locations. They are very suitable for lighting in coal washing plants.

|

Lamp type |

Lamp picture |

Application area |

|

Trestle roads, on-site roads, unloading dockes, loading docks, etc. |

||

|

Storage yard, belt conveyor corridor, transfer building, shipping dock, etc. |

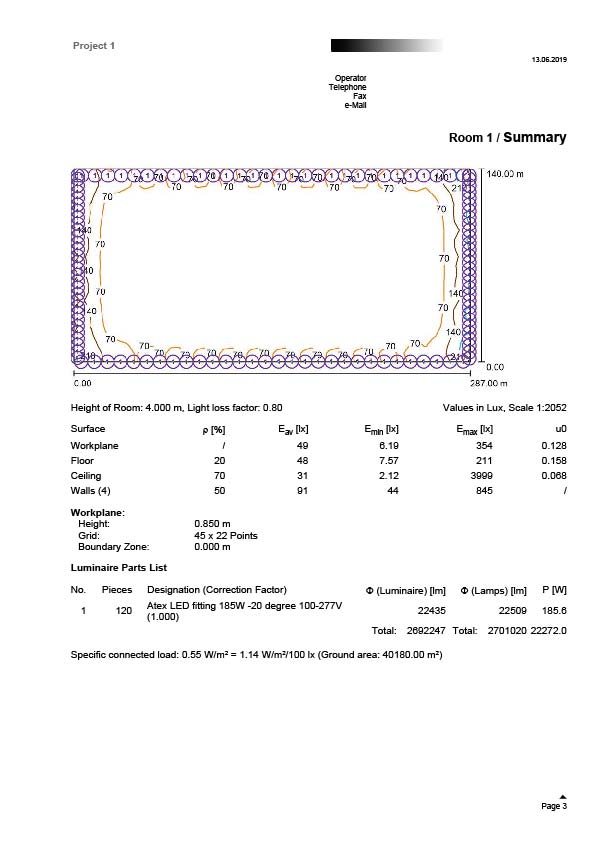

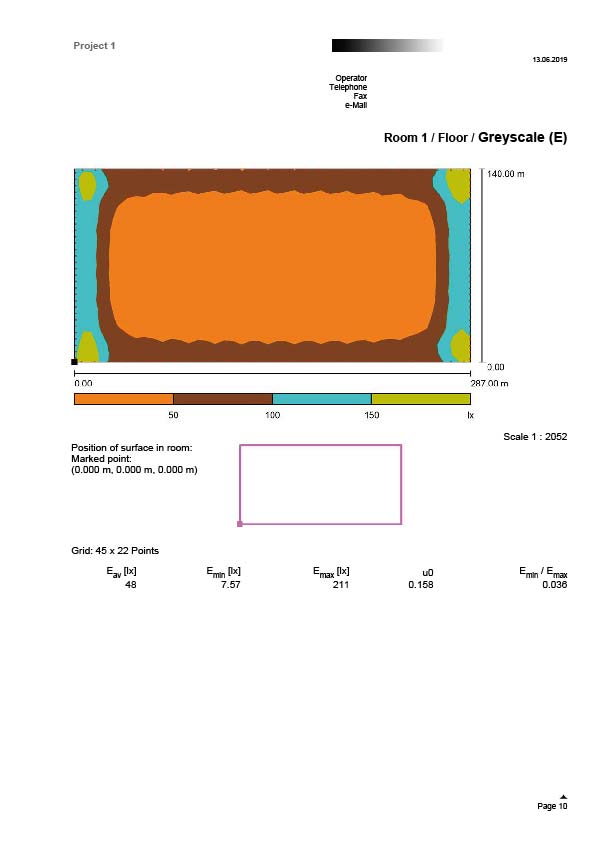

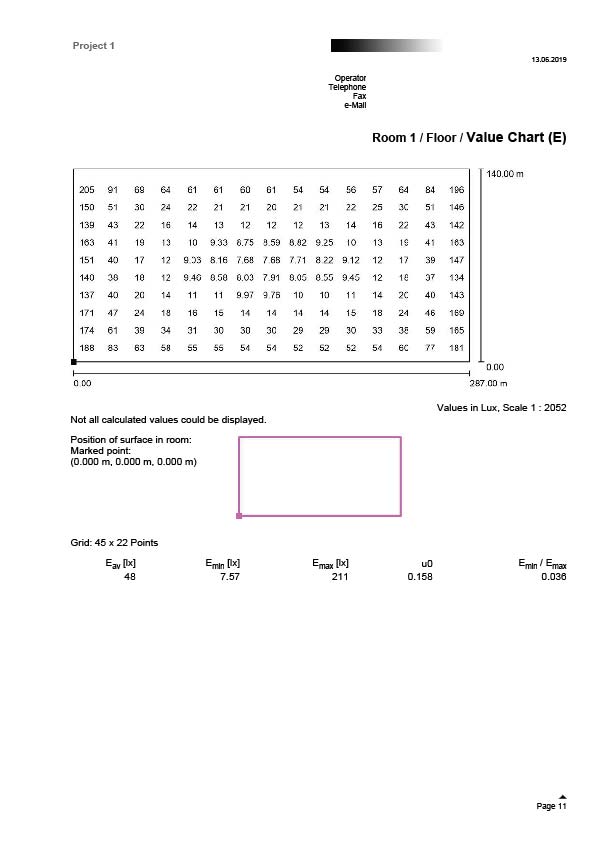

185W LED explosion-proof lighting design reference for coal mine lighting:

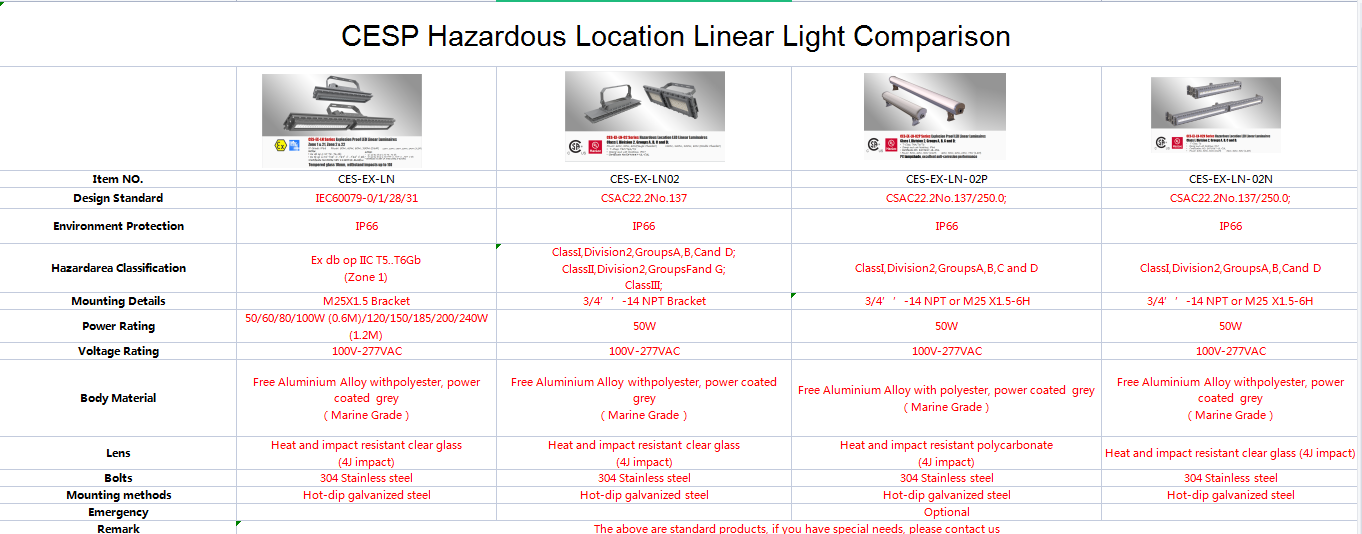

How to choose the CESP LN series explosion-proof linear lamp

CESP is a state-level high-tech enterprise and a contract energy management company that has been filed by the three ministries and commissions. CESP strive to high quality patent product in military & industry areas, is the Top OEM & ODM supplier for explosion proof lighting solution of China and the 1st Company in China to be certify for hazardous location led lighting fixture by UL & CUL.

Due to different market certification standards, CESP divides the line lights into CES-EX-LN, CES-EX-LN02, CES-EX-LN-O2P and CES-EX-LN-02N in order to meet the demand of the whole market, which are Zone System and Division System respectively.

- Basic product parameters

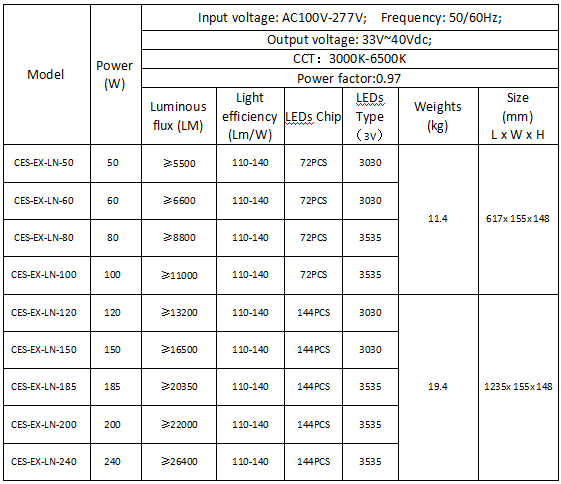

CES-EX-LN (Zone Explosion proof LED Linear Light)

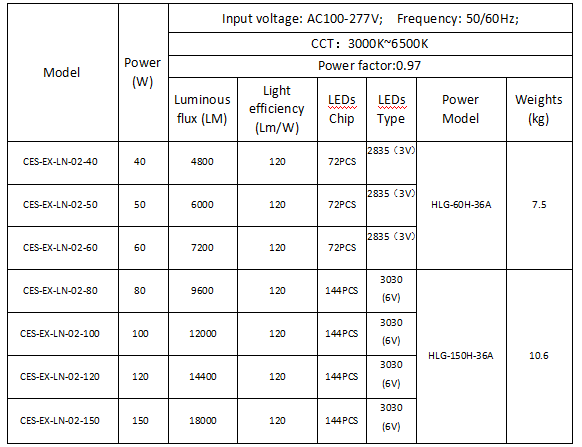

CES-EX-LN02(Division Hazardous Location LED Linear Lamp)

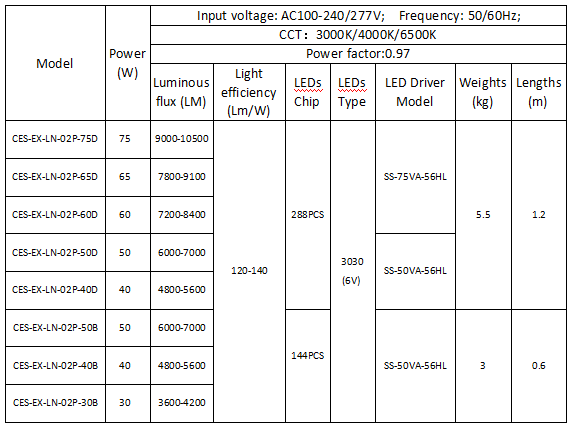

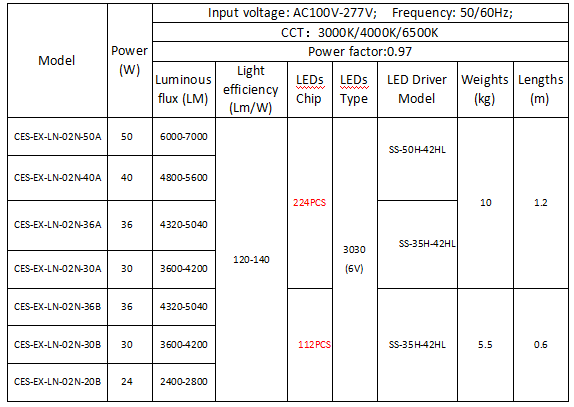

CES-EX-LN-02P(Zone and Division Hazardous Location LED Linear Light)

CES-EX-LN-02N(Division Hazardous Location LED Linear Light)

- Competing goods analysis

Most of the explosion-proof lamps and explosion-proof tri-proof lamps on the market are made of incandescent lamps, fluorescent lamps, high pressure metal gas discharge lamps and other lamps. This kind of lamps has mature technology and comfortable vision, and is widely used in indoor and general lighting, outdoor work lighting, but its disadvantages are obvious when working lighting.

- Poor environmental adaptability, it often fails to work normally in a low temperature environment;

- The safety factor is low, especially for gas discharge lamps such as metal halide lamps. The temperature of the lamps is high during operation, which is easy to become a hidden danger of safety accidents;

- There are many faults and maintenance is difficult. Once the lamp is damaged, it cannot be repaired in time, which will seriously affect the safety of night production;

- Poor vibration resistance and easy to damage. For example, the drilling offshore equipment has strong vibration, especially during the relocation process. The lamp tubes made of glass are often damaged and need to be replaced in large quantities, resulting in a lot of manpower and material loss, and mercury vapor and broken glass are returned to the environment. Cause harm;

With the continuous development of social productivity, LED technology continues to make breakthroughs. At present, white LEDs with luminous efficiency above 120Lm/W have been mass-produced. It has become the fourth generation of electric light sources after incandescent lamps, fluorescent lamps, and high-pressure metal gas discharge lamps, and is called the ultimate form of electric light sources.

The lamp beads used in the CESP explosion proof LED linear lamp LN series are high-quality LM80 certified chips, with a color temperature of 6000K and a color rendering index greater than 70. It can present colors and details more accurately than high-pressure sodium lamps or mercury vapor lamps. The luminous efficiency is as high as 140LM\W. such as the 50W hazard-area LED Linear light can produce 5500LM, 90° or 120° beam angle, which can meet the requirements of industrial lighting.

The copper-free aluminum alloy lamp body is powder-coated, which not only increases the strength and durability of the shell, but also improves the beautiful appearance. The combination of special heat dissipation design and LED technology helps the line lamp achieve an excellent rated life of 50,000 hours and an environmental adaptability of -40-+55°C.

The shell glass is made of high-strength tempered glass, which has been tested by internal pressure and hydraulic pressure. The anti-corrosion grade is WF2 and the IP grade is IP66. And this series of hazardous environment linear lights have multiple voltage capabilities and can work under 100-277 VAC, 50/60Hz without any special ballasts.

In general, this series of LED explosion-proof lights fixture are beautiful in appearance and powerful in function. They can accept ceiling, hoisting, pole mounting, wall mounting and other installation methods. They are very suitable for wastewater treatment, oil and gas refineries, drilling rigs, petrochemical facilities, food and beverage facilities, tunnels, outdoor wall and stanchion mounted general area lighting, and where flammable vapors, gases, ignitable dusts, fibers or flyings are presen.

- Product Performance Analysis

For the needs of the global market, the features of the four lamps of the CESP linear lamp LN series are different.

CES-EX-LN series is a zone system with ATEX/IECEX certification flameproof enclosure explosion-proof linear lights, can be used in Zone 1&21, Zone 2&22 and other hazardous environments. Its power supply cavity and light source cavity are independent sub-cavities. The explosion-proof performance is reliable. The toughened glass is designed for impact resistance, and the thickness of 10mm can withstand an impact of 7J. And after the hydraulic test, the Zone 1 lamp has superior sealing performance, and can be suitable for working under water (3 meters).

CES-EX-LN-02 is an explosion-proof linear lights with UL certification for Division system, which can be used in Class I, Division 2, Groups A, B, C and D; Class II, Division 2, Groups F and G; Class Used in hazardous environments such as III, the toughened glass is designed for impact resistance, 6mm thickness can withstand 4J impact, super strong structural strength, with optional emergency functions, suitable for general area lighting for tunnels, outdoor walls and pillars installation. The first choice to replace traditional fluorescent lamps.

CES-EX-LN-02P is a explosion proof tri-proof lamp with UL certification for Division system and ATEX/IECEX certification for Zone system. It can be used in hazardous environments such as Class I, Division 2, Groups A, B, C and D. , And used in hazardous environments such as Zone 1&21, Zone 2&22, it is the only explosion-proof lamp in the line lamp series with North American and European standards. It is the most cost-effective linear lamp in CESP. Its mask can withstand 4J impact. The upper temperature limit can reach 130°C. It has better corrosion resistance and is suitable for lighting with lower installation heights. It is the first choice to replace traditional fluorescent lamps.

CES-EX-LN-02N is a Division system with UL certification of explosion-proof linear lighting, which can be used in hazardous areas such as Class I, Division 2, Groups A, B, C and D; although the appearance is the most in the LN series a compact linear lamps, but still strong, the design of toughened glass is impact resistant, and the thickness of 6mm can withstand the impact of 4J. It is very suitable for lighting with lower installation heights, and it is an alternative to traditional fluorescent lamps, incandescent lamps and other lamps. The product of choice.

The following is a comparison of explosion-proof signs and parameters of different systems of LN series linear lights.

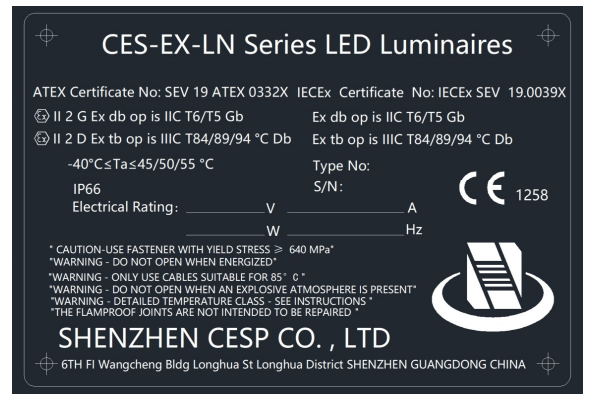

- Product appearance and naming analysis

CESP's explosion-proof lights are mainly gray in appearance. From the appearance, gray explosion-proof lamps are more beautiful and atmospheric, and adapt to the lighting environment of industrial areas, and meet the needs of target consumers for appearance colors. The name of the LN series is also simplified from the word Linear. The following is the naming connotation and nameplate analysis of each lamp.

- CES-EX-LN-W-A-B-C-D-E

CES - SHENZHEN CESP ;

EX - Hazardous Locations;

LN – Linear ;

W - Power;

A – Configuration, 01: Linear ;

B – CCT, 01:3000K; 02: 4000K; 03: 6500K ; 04: 5000K; 05: 5700K…

C- Mounting, 01:Ceiling Mounting; 02: U- bracket;

D-Color, 01: Yellow; 02: Gray…;

E-other, Commercial purpose

- CES-EX-LN-02-W-A-B-C-D

CES - SHENZHEN CESP ;

EX - Hazardous Locations;

LN - Linear;

02 - Division 2 ;

W - Power;

A – Configuration, 01:Line;

B – CCT, 01:3000K; 02: 4000K; 03: 6500K ; 04: 5000K; 05: 5700K…

C- Mounting, 01:Ceiling mount ; 02: U- bracket,;

D-other, Commercial purpose

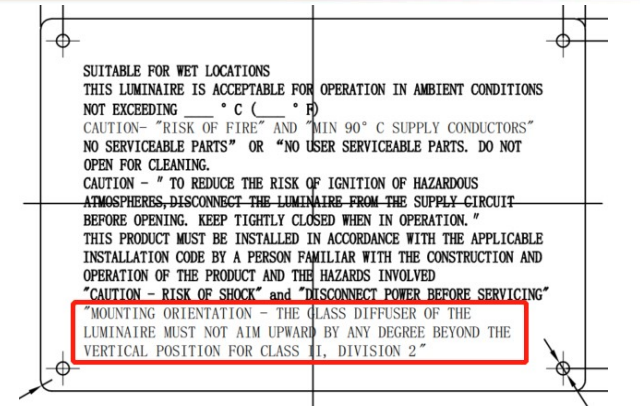

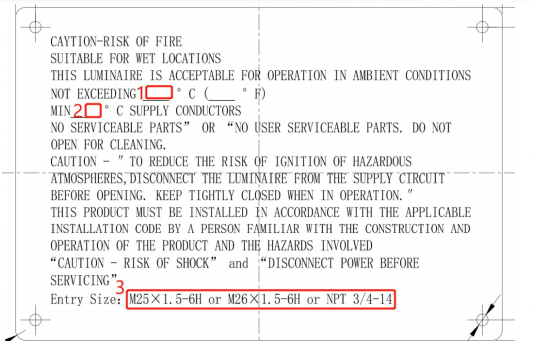

Note 1: Use the maximum value of the ambient temperature Ta 40/45/50°C (optional according to customer requirements) and write Fahrenheit at the same time;

Note 2: The red box is only marked in the case of double cavities, and the single cavity does not need to be marked;

- CES-EX-LN-02P-WX-A-B-C-D

CES - SHENZHEN CESP ;

EX - Hazardous Locations;

LN - Linear ;

02 - Division 2 ;

P - Design features, Polycarbonate;

W - Power;

X - Size, B: 0.6m, D: 1.2m;

A – Configuration, 01:Line;

B – CCT, 01:3000K; 02: 4000K; 03: 6500K ; 04: 5000K; 05: 5700K…

C- Mounting, 01: Drop mount; 02: Ceiling mount ; 03: Wire colour; 04:Pole Mounting;

D-other, Commercial purpose

Note 1: The maximum value of the ambient temperature Ta is 45/50/55°C (optional according to customer requirements);

Note 2: The unified default is 90°C;

Note 3: Choose according to customer requirements, default NPT3/4-14;

- CES-EX-LN-02N-WX-A-B-C-D

CES - SHENZHEN CESP ;

EX - Hazardous Locations ;

LN - Linear ;

02 - Division 2 ;

N - Design features:Narrow;

W - Power;

X - Size, A: 1.2m, B: 0.6m;

A – Configuration, 01:Line;

B – CCT, 01:3000K; 02: 4000K; 03: 6500K ; 04: 5000K; 05: 5700K…

C- Mounting, 01:Ceiling mount ; 02:U- bracket;

D-other, Commercial purpose

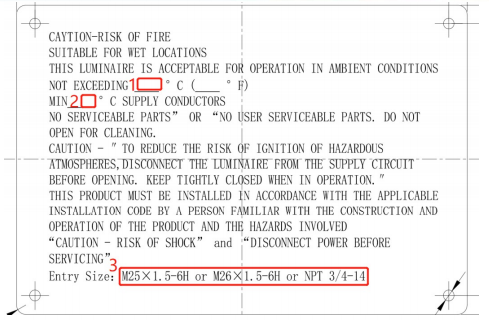

Note 1: The maximum value of the ambient temperature Ta is 45/50/55°C (optional according to customer requirements);

Note 2: The unified default is 90°C;

Note 3: Choose according to customer requirements, default NPT3/4-14;

- other aspects of analysis

In terms of parts procurement and supply chain, while implementing localization, it actively promotes the globalization of the domestic parts industry. The parts of explosion-proof lamps are completely purchased by manufacturers in global model factories, and the parts are guaranteed to be of high quality. During the design and production, the power supply cavity and the light source cavity were adjusted according to the explosion-proof certification requirements of different regions, and the heat dissipation system specially designed by industrial designers was used to enhance the safety performance of the explosion-proof linear lamp.

And with the continuous research and development of products, LN series explosion-proof lamps have also derived derivative products. If the customer needs the emergency function of the strip light, and wants to not affect the original installation method, you can choose CES-EX-LN-02P, built-in emergency power supply, this explosion-proof linear light neither installs nor affects the appearance, and The emergency time is around 90min,If the customer has no specific requirements for the installation method, you can also choose CES-EX-LN-02N series lamps or CES-EX-LN series explosion-proof lamps, add an independent emergency power cavity to place emergency drives and batteries, and the minimum can be used for 90 minutes, with emergency power 12W; Or customers who want better wiring and cost-saving, they can also choose CES-EX-LN-02P, which can output the wires at the same time, which perfectly solves the customer's customized needs.