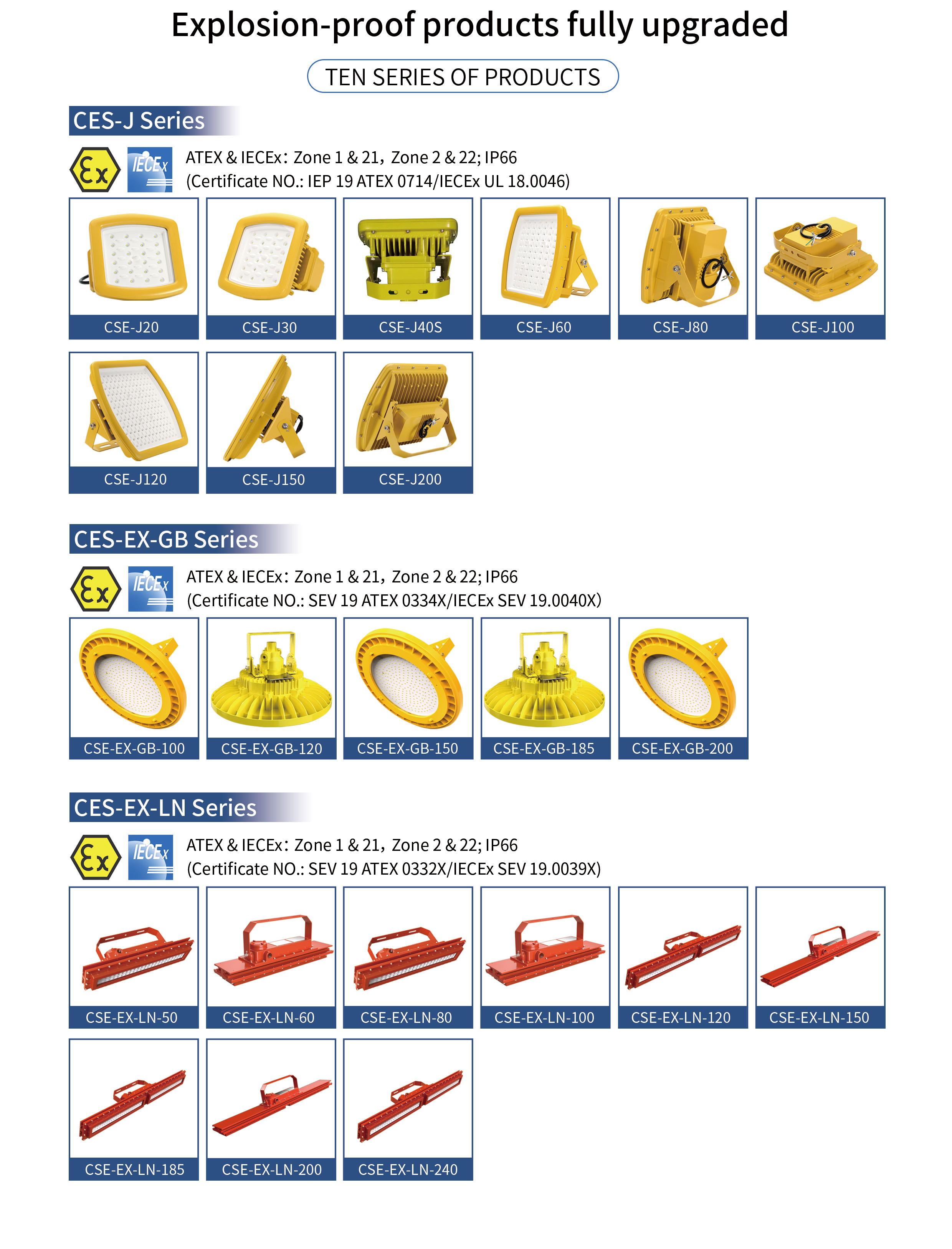

IECEx ATEX Certified Explosion proof LED Lights - Zone 1 Zone 2 Hazardous Area Lighting

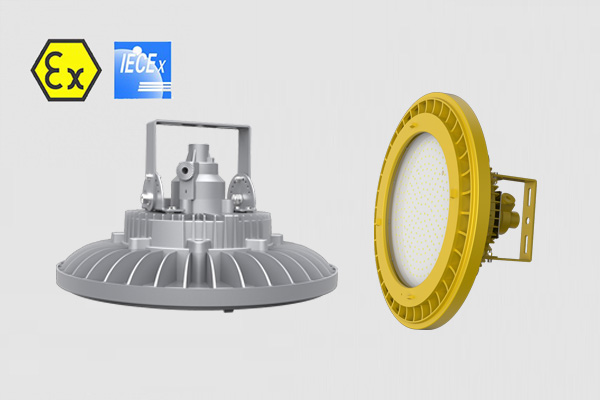

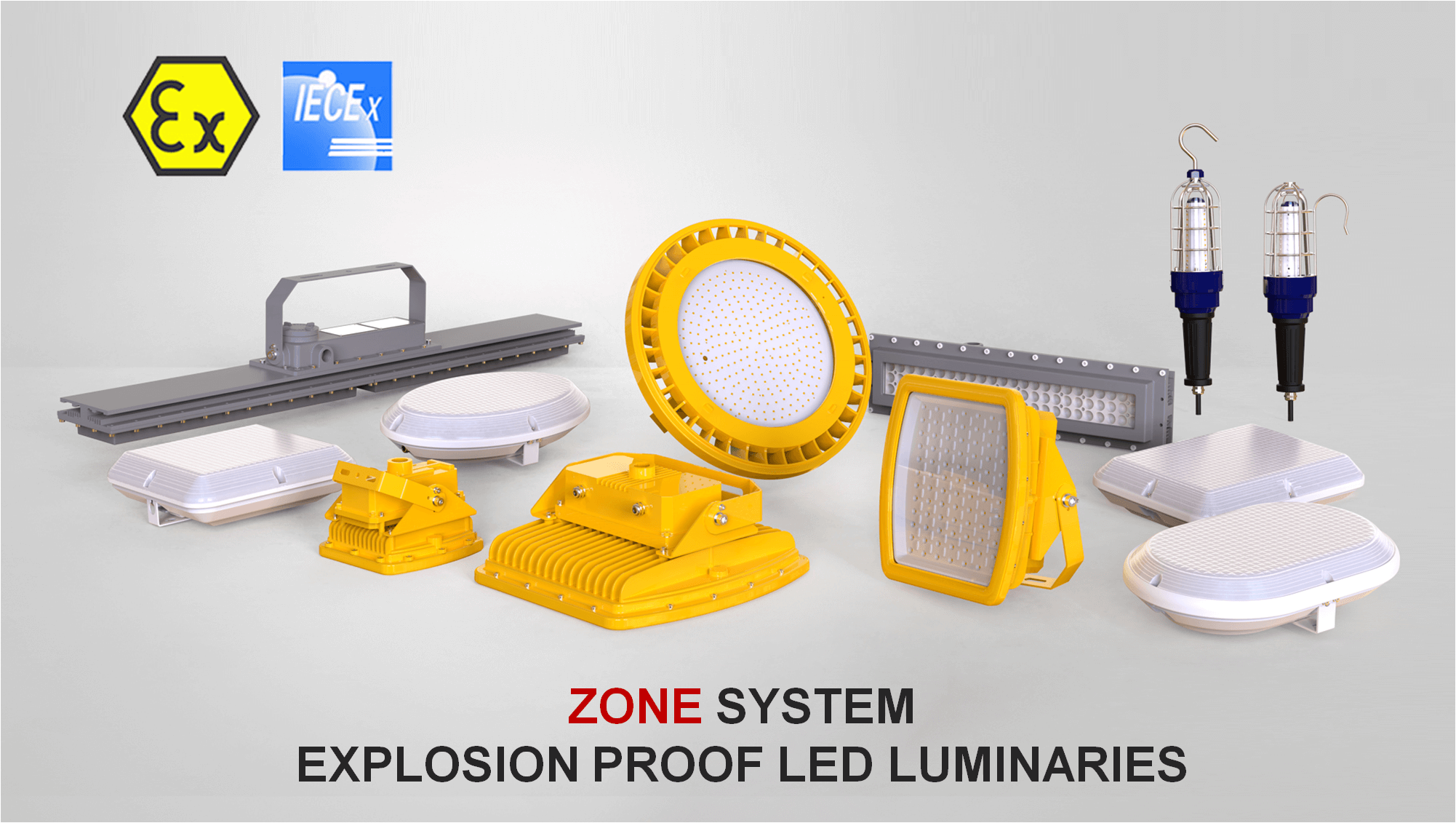

For Zone 1 Zone 2, Zone 21 Zone 22 hazardous area led lighting, 20W - 200W, 130lm/W,aluminum alloy + 8mm tempered glass, multi-installation for different projects, such as light tower, canopy light, marine grade.

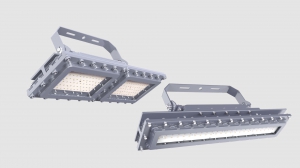

Flameproof enclosure, Ex db op is IIC T6 Gb, Zone 1 & Zone 21 with explosive gas atmosphere, Zone 21 and Zone22 with explosive dust atmosphere, 10mm temered glass, 7J impact resistance,up to 26000lm.

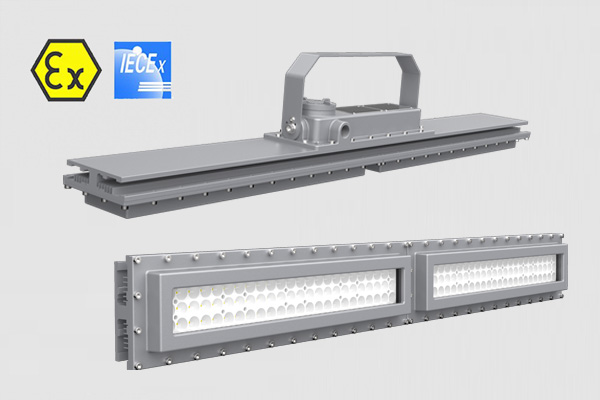

Flameproof enclosure, Ex db op is IIC T6 Gb, IP68 protection grade, tempered glass 10mm, withstand impacts up to 10J, 2 foot and 4 foot Length, 50Watt- 240Watt, 130lm/W light efficacy.

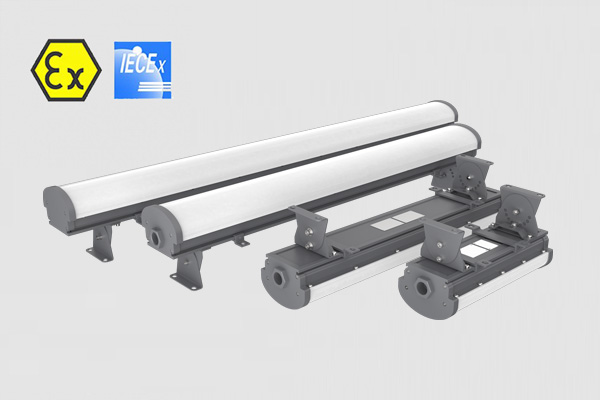

Zone 1 & Zone 21, 1ft, 2ft, 3ft, 4ft length can be selected, replace the traditional explosion-proof three-proof lamp, explosion-proof fluorescent tube, anti-corrosion, anti-glare, anti-drop, competitive price.

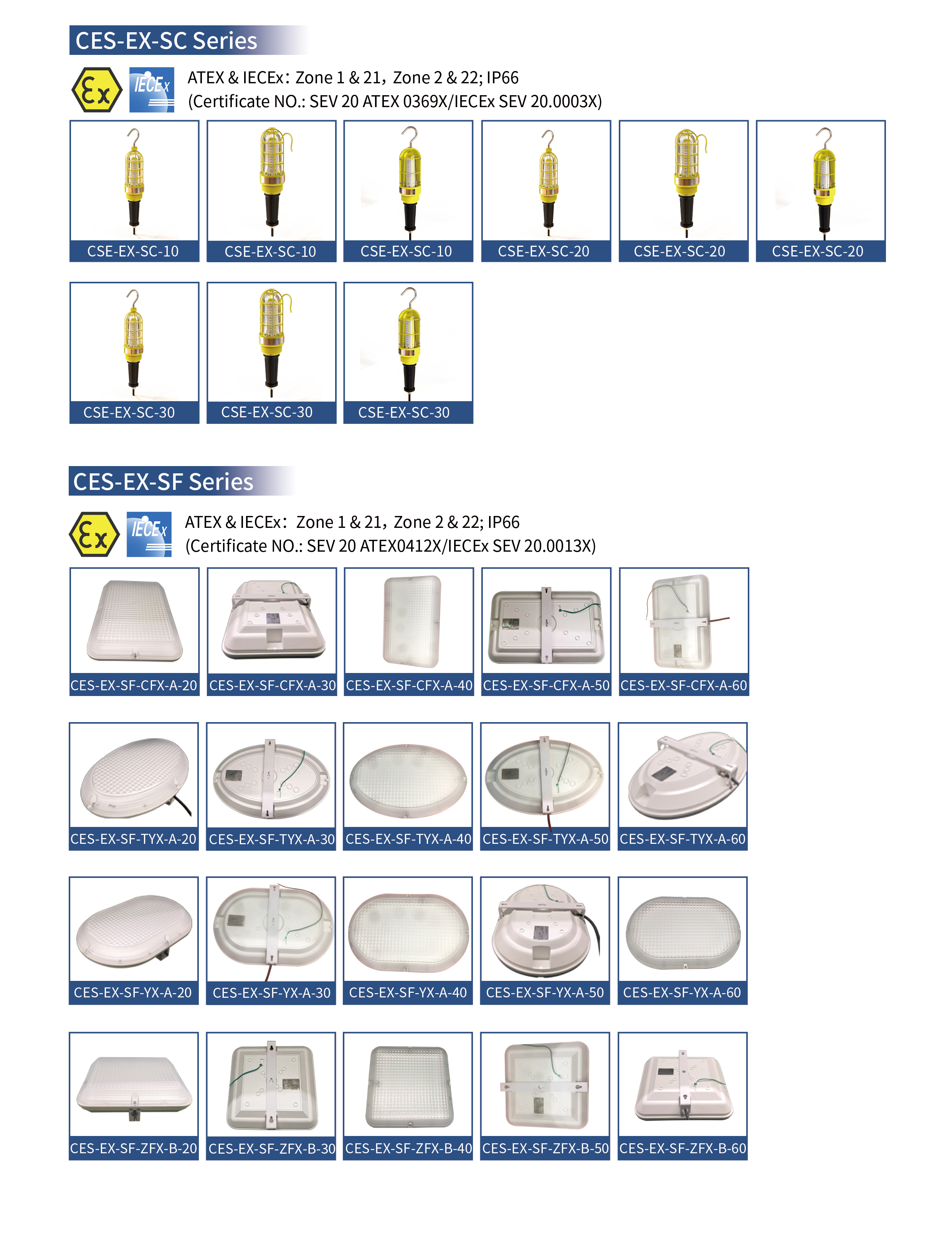

Flameproof LED hand lamp for Zone 1 & Zone 21 hazardous areas, 10mm tempered glass, pass the multi-angle drop test, 10W, 20W, 30W Power, can be connected to the cable, emergency power box.

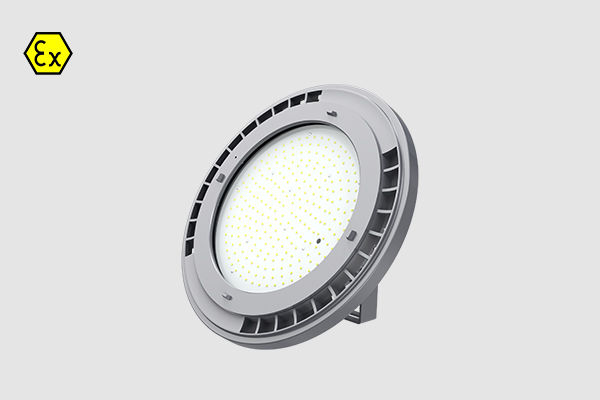

The CES-EX-SF series explosion-proof ceiling lamp has a strong shell, with features such as impact resistance, vibration resistance, and corrosion resistance. It can be used in hazardous environments of Zone 1&21, Zone 2&22.

CES-EX-JX Series is your go-to solution for illuminating hazardous Zone 1 and Zone 21 areas. With ATEX approval, these Explosion-proof LED Flood Lights offer unbeatable safety standards.

Discover the pinnacle of safety and illumination with our CES-EX-GBX Series Explosion-proof LED High Bay Lights. Designed for hazardous Zone 1 and Zone 21 areas, these lights boast ATEX approval, ensuring the highest safety standards.

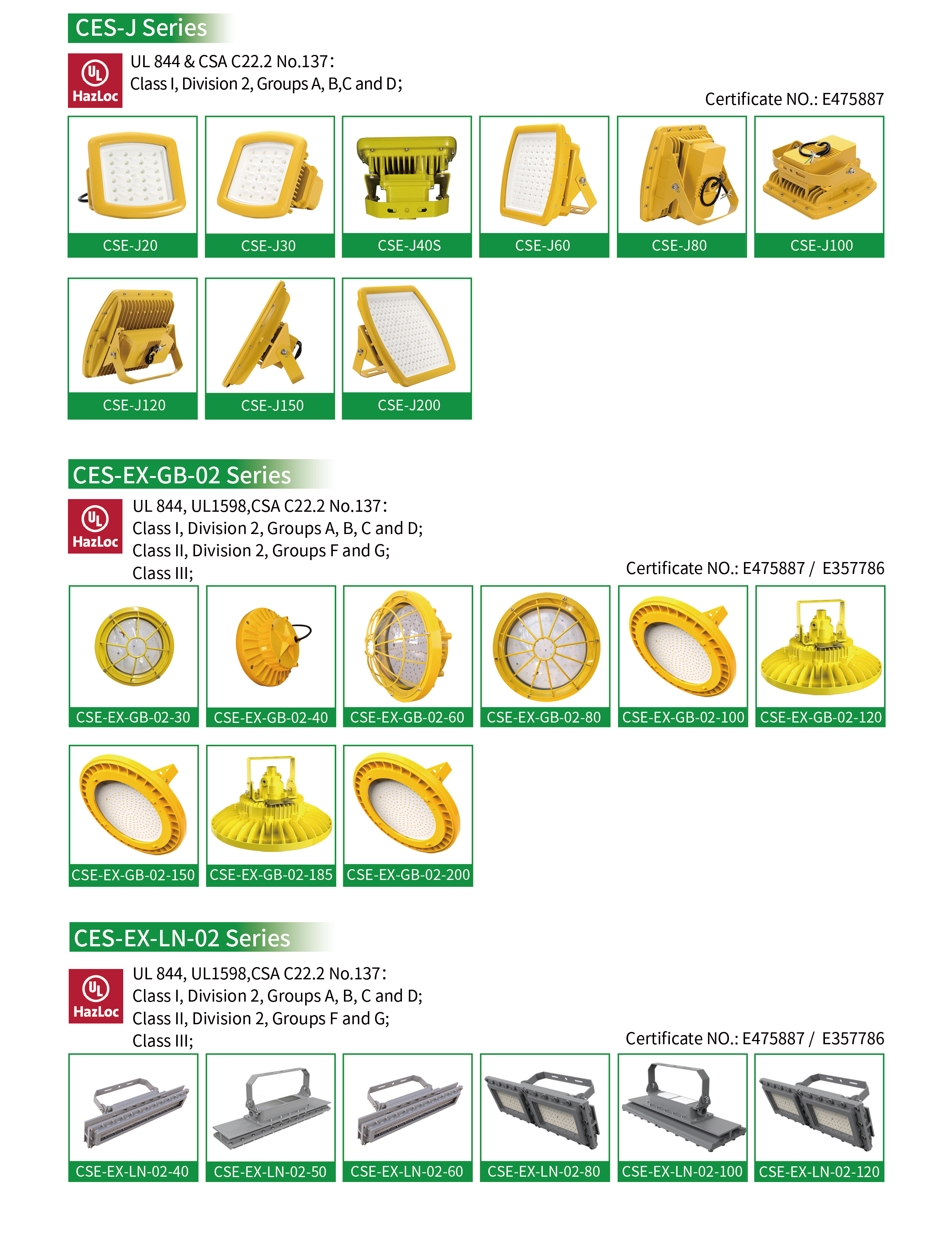

GB-02 explosion-proof lights are made of alloy aluminum and tempered glass, with shock resistance and anti-vibration performance. The luminaires have passed the ATEX IECEx standards test, from 30W to 80W for hazardous area lighting.

LN-02 explosion-proof lights obtained an IECEx ATEX certificate, it's safe for the Zone 1 and Zone 2 hazardous locations. The copper-free aluminum alloy body is powder-coated to increase durability and beautiful appearance, are able to withstand violent shaking and shock resistance.

an innovative line of LED hazardous area lighting products, specifically designed for use in potentially explosive atmospheres (Zone 1/21 & 2/22) within harsh industrial settings such as coal mines and oil & gas facilities.

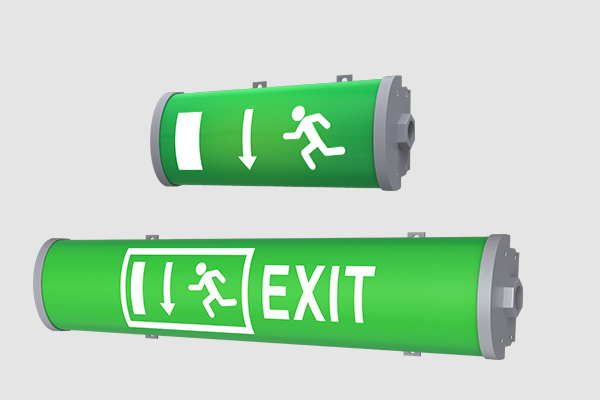

Explosion-proof safety exit lamps are for personnel evacuation, and fire operations to provide lighting fire emergency lamps! It usually uses an external power supply, when the power automatically switches to the battery power state!

Spray Paint Booth Lighting Solution

Spray Paint Booth is a flammable and explosive environment. The electrical appliances, circuits, and lighting fixtures used must all have electrical regulations of different countries.

Part 1. Common Spray Paint Booth is divided into the following categories

A. Dry Spray Paint Booth

Dry spray paint booths

In each spray booth, the arrangement of the paint mist filter holes will produce a cyclone effect, forcing paint particles to fall on the bottom of the booth, and the airflow will be discharged from the filter, which effectively removes paint mist particles. From this cyclone effect. Depending on the nature of the spray paint product, the filtration rate reaches 96%. Even with the kind of high-performance paint, the surface is rarely blocked. Dry paint mist filter can block every tiny particle.

Features of Dry Paint Booth

- Dry spray booths are the development trend of spray painting operations with low output (limited to working environments with small spray volume)

- The dry spray booth first uses paint mist filter cotton and then uses an activated carbon purifier to filter, and some add a paint mist filter cotton before the activated carbon to extend the life of the activated carbon;

- The simple dry spray booth is very simple to use activated carbon filter;

- The paint mist filter cotton can be reused, and the time is determined by the specific working conditions of the manufacturer;

- Under normal operation, there are no more fire hazards than families;

- The investment is less than that of the wet type, and the operating cost is not high.

B. Water curtain Spray Paint Booth

The characteristic of water curtain Spray Paint Booth is to use the flowing curtain-like water layer to collect and take away the paint mist. The exhaust device ensures that the paint mist does not escape and maintains a good working environment in the workshop. Water curtain Paint Booth is mainly composed of chamber body, tank body, water curtain board, water circulation system, spray system, steam water separation system, slag removal system, exhaust system, etc.

Features of Water curtain Paint Booth as follow,

- Purification efficiency reaches the standard-spray paint mist removal rate ≥90%. The removal rate of hydrophilic dust above 5μm is ≥96%

- Reliable work and operation-safety explosion-proof centrifugal fan is assembled as exhaust device and water circulation power device. Parts that are not prone to failure and frequent maintenance, so the equipment is very reliable.

- Simple operation and maintenance-the basic operation is to start and stop the fan (press a button);

- Convenient and flexible installation-all are modular design, which can be easily combined according to the painting workpiece and process requirements. No special installation foundation and civil construction are required. It is more suitable for the environmental protection equipment installed in the renovation plant.

- Various types of front rooms-suitable front room types and specifications can be selected according to the user's plant conditions and process characteristics.

- No waste water gas discharge-the discharged waste gas is purified by circulating water (special flocculant is added to the water), and the water will evaporate naturally. Therefore, no waste water is discharged. The paint slag remaining in the circulating water can be removed regularly.

- Convenient maintenance in later period-easy maintenance, reliable equipment performance, not easy to malfunction, and easy to use;

- Excellent purification efficiency-due to the air containing paint mist, through the water curtain, water curtain, and the strong mixing and stirring of the water mist in the air-water channel, a multi-stage purification process is formed, which improves the purification efficiency;

- Easy to clean up residues-adding flocculant to the water solves the trouble of paint fog sticking to the equipment, and is easy to clean up to ensure the ventilation effect.

C. Water Spinner Paint Booth

The hydrocyclone type Spray Paint Booth is generally a top-feeding-down exhaust type, and a hydrocyclone structure is used to remove paint mist. It is mainly composed of chamber body, air supply system, paint mist filter system, exhaust system, water circulation system, hydrocyclone, etc. The main principle is: according to the atomization principle of the gas-liquid two-phase mixture, if the speed of water and air is very different, the water can be atomized well in the air, and then fully contact and condense with the paint mist, and finally the water and air The paint is left in the water, and then the water is reprocessed. Water spinner Paint Booth is a large-scale Paint Booth that is currently used more frequently.

Features of Water Spinning Paint Booth as follow,

- The indoor air flow is stable and the paint mist does not scatter.

- Simple structure and quick construction.

- High-efficiency paint mist purification, purification efficiency ≥98%.

- Automatic constant temperature air supply during winter painting

Part 2. The reason why Spray Paint Booth is flammable and explosive

- There is no independent paint spraying room and paint mixing room. Many spray booths generally adopt an open layout, and the surroundings and ceilings are not effectively isolated or closed, and do not meet the national standards for spray booths; some companies have simple job sites, and the paint mixing process is carried out directly in the spray job site. The barrel is left open at will, which is extremely dangerous.

- There is no dedicated hazardous chemical warehouse. Some companies mix paint, thinner, and other items in a warehouse, and some companies even place them directly at the spraying site. Once they encounter an open flame, the fire will spread quickly, with disastrous consequences.

- Insufficient fire separation distance between spray booths. In some companies, the safety distance between the spray booth and the drying operation facility, and the electric welding and gas welding operation site is seriously inadequate.

- The electrical facilities do not meet the requirements. The electrical facilities of many companies' spraying workplaces, such as lighting fixtures, exhaust fans, etc., are general electrical appliances, and no explosion-proof measures have been taken. Temporary wiring, disordered wiring, and the use of ordinary sockets are more common.

- The ventilation effect of the spray booth is poor, and the exhaust air system cannot meet the process safety requirements. During the spraying process, paints and thinners will volatilize a large amount of flammable and explosive mixed gas. The poor ventilation effect directly leads to the accumulation of dust and coating mist, and it is easy to reach the explosion limit of the gas, and encounter sparks generated by open flames or static electricity. , There will be an explosion in an instant.

- On-site management is generally poor. There was a lot of paint waste in the spray booth, and they could not be cleaned up in time.

- The production equipment lacks necessary safety devices and effective measures to eliminate static electricity. Pneumatic spraying operation spray guns and other spraying equipment are not grounded statically, and it is easy to form static electricity accumulation and discharge.

- Insufficient fire-fighting equipment in spraying workplaces and warehouses, and no safety signs and safety cordon lines have been hung.

- The fire-fighting passage in the spraying work site is not smooth. The overall layout of the spraying workplace is unreasonable, and raw materials, semi-finished products, finished products and other materials are stacked at will, causing serious blockage of the fire-fighting passage.

- Anti-static work clothes, protective glasses, conductive shoes and other protective products are not equipped in accordance with the specifications or used correctly during spraying operations.

- Business owners don't pay enough attention to safety production, lack of specialized safety production management personnel, safety production rules and regulations are not sound, enterprise safety production investment is insufficient, and safety investment is too much in debt.

- Business owners and practitioners lack the proper understanding and understanding of the dangers of paints, coatings, and thinners used in spraying operations.

Part 3. Spray Paint Booth lighting requirements

For Paint Booth, the appropriate light source illuminance is a very important indicator. Its importance is reflected in the fact that for some workpieces with a relatively flat painted surface and a relatively simple structure, a slight lack of illuminance is acceptable, but for some workpieces with complex structures, it is very important if the illuminance of the light source is insufficient. It may cause a series of painting problems such as excessive thickness, thinness, leakage, flow, etc. in some parts of the spray paint. At this time, it is necessary to use special lamps for hazardous locations.

Illumination: The brightness of Paint Booth needs to reach 800-1000lux, and it needs to be close to D65.

At the same time, the inner wall of Paint Booth should be matte white. When using partitions made of transparent materials such as glass for lighting, fixed luminaires should be used as light sources, and partitions should be used to separate the area where the luminaires are installed from the electrostatic paint area. The installation gaps should be reliably sealed. The material of the partitions is It is non-flammable and not easy to break, and the thickness of the deposit on the partition shall not affect the specified illuminance.

Enclosed explosion-proof is required: Paint is a flammable chemical. When the paint reaches a certain concentration in the air, it will burn and explode when it encounters a high-temperature open flame. And Paint Booth is a place where paint does not exist all the time, and explosion proof led lights can meet this point of explosion and safety.

The fire hazard of the Paint Booth workshop is related to the type of paint used, the method and amount of Paint Booth used, and the conditions of the Paint Booth site. When flammable coatings and organic solvents are used, there is a greater risk of explosion and fire. Explosion and fire accidents will cause serious loss of life and property, and seriously affect the normal production of production.

Paint Booth lighting fixtures should be powered by explosion-proof lamps in hazardous areas, and the grade must be at least IIC explosion-proof: safe, explosion-proof, and energy-saving. The standard lighting voltage is AC 220V. According to special engineering needs, AC 127V or DC 36V may be used.

Part 4. CESP Explosion proof LED Lights for Spray Paint Booth

CESP LED explosion-proof lights have all obtained North American explosion-proof certification. Class I Division 2 LED explosion-proof lights and IECEx, ATEX Zone1 LED Lights are suitable for Spray Paint Booth Lighting.

CES-EX-LN-02P Series is more cost-efficient as the spray paint booth light, if you need a detailed lighting solution, please provide paint booth drawings, or the Booth Dimension. Our R&D department will provide professional lighting solutions for you.

Tab.: Spray Paint Booth Light, Paint Booth Lighting, Paint Spray Booth Lighting, Paint Booth LED Light Fixtures

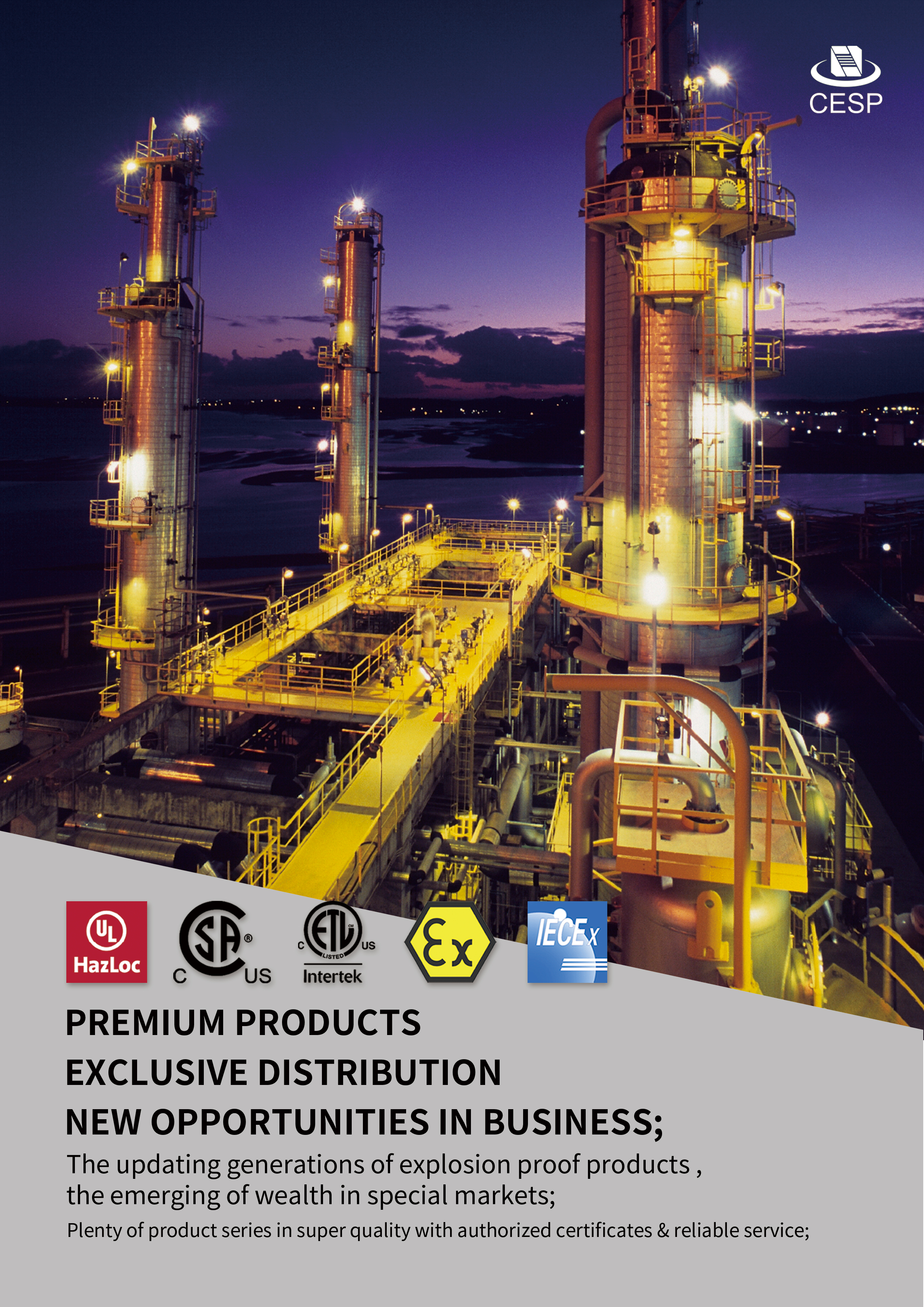

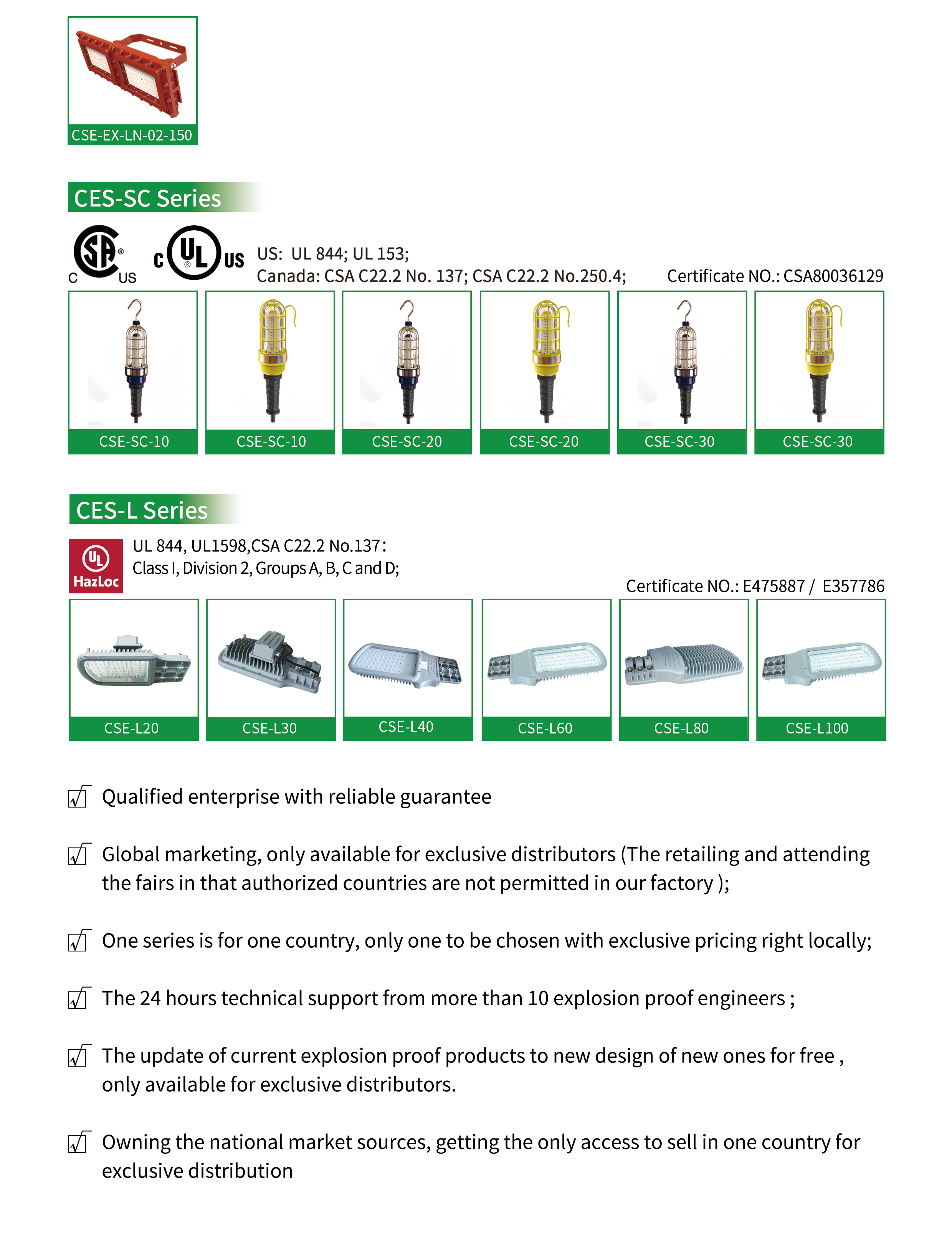

CESP is Recruiting Exclusive Agents from All Over World.

Copy of Accident Analysis of Cold Storage

- Cold storage building and thermal insulation characteristics

Cold storage: a warehouse that uses cooling facilities to create suitable humidity and low temperature conditions. Also known as cold storage. It is a place for processing and storing products. It can overcome the influence of climate, prolong the storage period of various products, and regulate market supply.

Cold storage is a storage building group with artificial cooling and cooling functions, including warehouse, refrigeration room, power transformation and distribution room, etc. In order to ensure that the temperature in the cold storage room is maintained within the specified range, the building envelope is often set with a certain thickness of the thermal insulation layer according to the storage temperature requirements. The good flame retardant performance of thermal insulation materials is one of the important factors to decrease the fire accident of cold storage. Before the 1980s, the commonly used thermal insulation materials in cold storage were cork and rice husks. Because of its high moisture absorption, easy decay after pyrolysis, and easy decomposition and combustion at high temperature, it was gradually superseded by EPS,PU and XPS.

According to the different building structures, cold storage can be divided into civil cold storage, combined cold storage, mixed cold storage, etc. The civil cold storage adopts reinforced concrete as the support structure of the warehouse, and its enclosure structure is brick concrete material with additional thermal insulation material. The combined cold storage adopts light steel structure as the supporting structure of the building, and the insulation material (combined cold storage insulation board) with a certain thickness of steel plate attached on both sides is the enclosure structure of the warehouse. The hybrid cold storage is usually a multi-layer cold storage, its structure body is reinforced concrete, and the box body is made of composite cold storage insulation board.

- Problems in cold storage

- Most warehouses use old-fashioned civil structures without beams

- Cold storage hall, platform design for open type

- Configuration of cold storage equipment

- Poor overall management of cold storage facilities

- Storage facilities backward

- Insufficient number of new combined cold stores

- Common accidents in cold storage

- Fire accident

In recent years, there have been frequent fires in the freezing storage industry, especially in an explosion-proof cold storage last year, which caused a great number of casualties and caused great losses to the safety of people's lives and property.

- Refrigeration system accident

Nowadays, most refrigerators utilize freon refrigeration. Freon belongs to grade IV mild toxic substances. Now most refrigerators use freon refrigeration. Freon belongs to grade IV toxic substances. However, the content of freon in the air reaches a certain degree, which can cause asphyxia. When the concentration of ammonia in the air is between 16% and 25%, explosion accidents may occur in case of open fire . Due to the frequent occurrence of quality accidents in cold storage systems, compressor damage and refrigerant leakage, many losses have been caused to enterprises.

- Cause analysis of common accidents

- Cause of fire accident

Combustibles, fire sources and combustion supporting materials are the three inevitable factors that cause the combustion of combustibles in a fire. As combustion supporting gas exists in the atmosphere, the causes of cold storage fire can only be analyzed from two aspects of combustible materials and fire source.

The thermal insulation materials for the pipes of cold storage buildings and equipment are the worst combustibles in the warehouse. Among the building materials used in the existing cold storage, the thermal insulation material of the cold storage has the highest combustion performance. Some common cases, such as Fengfeng poultry Co., Ltd. and Food Co., Ltd., are all caused by the burning of thermal insulation materials. In addition, in the early 1990s, the welding operation outside a prefabricated cold storage warehouse in a city caused a fire of the insulation material of the refrigeration pipeline, which rapidly expanded to the insulation wall of the cold storage along the insulation pipe, causing the cold storage fire and the steel structure of the cold storage collapsed. The main body of combustibles is the insulator.

The main causes of fire accidents in cold storage are electric gas welding, cutting operations, short circuits of cable, illegal use of open fire and so on. In 2015, there were 54 cold storage fire accidents, of which 65% were caused by electrical welding, cutting and other operations ;6% were caused by illegal use of open fire ;29% were caused by short circuit of electrical lines ;29% were caused by strong concealment; and 6% were caused by carelessness.

- Failure of refrigeration system

The cause of failure of refrigeration unit can be divided into refrigeration system without reasonable maintenance, often small work, running with disease, after the construction of cold storage, must not ignore, resulting in equipment annual inspection is not up to standard, aging accelerated, Thus occurs the refrigeration system ammonia refrigerant exposure phenomenon. Secondly, the cold storage design project is not perfect, unlicensed design, no professional technology installation construction, some cold storage cost is low, some cold storage construction enterprises choose a large number of defective or second-hand materials, so that the safety of cold storage can not be effectively guaranteed.

Normal use of cold storage fires, insufficient air, inadequate combustion, high carbon monoxide content. The acute lethal concentration of carbon monoxide is only 0.5, colorless and tasteless, and the activity is very strong. If the personal protection of firefighters is not in place, acute poisoning easily occurs. Accordingly, the equipment and facilities of the cold storage should select some mechanical products that meet the requirements of safety certification, such as UL、CSA、ETL、IECEx-CB certification, so as to avoid accidents caused by fire, poisoning and other auxiliary equipment caused by the equipment itself.

CESP explosion-proof linear lamp obtained ATEX/IECEx/UL certification, suitable for Zone1&21,Zone2&22 hazardous areas, can fully meet your advanced explosion-proof requirements. Die cast aluminum shell made of high technology core pulling system is used in the shell. At the same time, the engineer has carried out a special design to improve the heat dissipation effect and make the life of explosion-proof lamps longer, which can reach more than 50000 HRS. Linear explosion-proof light also uses high-quality LEDlm80 lamp beads, while saving energy and environmental protection, but also has strong light-effect lighting. Light reflection cup design, folding 120 degrees.

With the increase of cold storage demand, the requirements for safety are gradually increasing. CESP focuses on the research and development, manufacture and sale of high-quality military patented products, it is a famous manufacturer OEM/ODM explosion-proof lamps in China and a supplier of lighting solutions in hazardous areas.

Description:With the continuous development of the cold chain logistics industry, the number of users who need to build cold storage is increasing. Once anything develops too fast, all kinds of malpractice will gradually emerge. Only in this way can the normal use of cold storage and the personal safety of employees be guaranteed.

Compact 20 Watt Led Tube Lamps T8 Explosion Proof For Cold Storage Food Factory for sale, China LED Tri Proof Lights wholesaler, China LED Tri Proof Lights manufacturer, China LED Tri Proof Lights exporter, China LED Tri Proof Lights company认证

Accident Analysis of Cold Storage

- Cold storage building and thermal insulation characteristics

Cold storage: a warehouse that uses cooling facilities to create suitable humidity and low temperature conditions. Also known as cold storage. It is a place for processing and storing products. It can overcome the influence of climate, prolong the storage period of various products, and regulate market supply.

Cold storage is a storage building group with artificial cooling and cooling functions, including warehouse, refrigeration room, power transformation and distribution room, etc. In order to ensure that the temperature in the cold storage room is maintained within the specified range, the building envelope is often set with a certain thickness of the thermal insulation layer according to the storage temperature requirements. The good flame retardant performance of thermal insulation materials is one of the important factors to decrease the fire accident of cold storage. Before the 1980s, the commonly used thermal insulation materials in cold storage were cork and rice husks. Because of its high moisture absorption, easy decay after pyrolysis, and easy decomposition and combustion at high temperature, it was gradually superseded by EPS,PU and XPS.

According to the different building structures, cold storage can be divided into civil cold storage, combined cold storage, mixed cold storage, etc. The civil cold storage adopts reinforced concrete as the support structure of the warehouse, and its enclosure structure is brick concrete material with additional thermal insulation material. The combined cold storage adopts light steel structure as the supporting structure of the building, and the insulation material (combined cold storage insulation board) with a certain thickness of steel plate attached on both sides is the enclosure structure of the warehouse. The hybrid cold storage is usually a multi-layer cold storage, its structure body is reinforced concrete, and the box body is made of composite cold storage insulation board.

- Problems in cold storage

- Most warehouses use old-fashioned civil structures without beams

- Cold storage hall, platform design for open type

- Configuration of cold storage equipment

- Poor overall management of cold storage facilities

- Storage facilities backward

- Insufficient number of new combined cold stores

- Common accidents in cold storage

- Fire accident

In recent years, there have been frequent fires in the freezing storage industry, especially in an explosion-proof cold storage last year, which caused a great number of casualties and caused great losses to the safety of people's lives and property.

- Refrigeration system accident

Nowadays, most refrigerators utilize freon refrigeration. Freon belongs to grade IV mild toxic substances. Now most refrigerators use freon refrigeration. Freon belongs to grade IV toxic substances. However, the content of freon in the air reaches a certain degree, which can cause asphyxia. When the concentration of ammonia in the air is between 16% and 25%, explosion accidents may occur in case of open fire . Due to the frequent occurrence of quality accidents in cold storage systems, compressor damage and refrigerant leakage, many losses have been caused to enterprises.

- Cause analysis of common accidents

- Cause of fire accident

Combustibles, fire sources and combustion supporting materials are the three inevitable factors that cause the combustion of combustibles in a fire. As combustion supporting gas exists in the atmosphere, the causes of cold storage fire can only be analyzed from two aspects of combustible materials and fire source.

The thermal insulation materials for the pipes of cold storage buildings and equipment are the worst combustibles in the warehouse. Among the building materials used in the existing cold storage, the thermal insulation material of the cold storage has the highest combustion performance. Some common cases, such as Fengfeng poultry Co., Ltd. and Food Co., Ltd., are all caused by the burning of thermal insulation materials. In addition, in the early 1990s, the welding operation outside a prefabricated cold storage warehouse in a city caused a fire of the insulation material of the refrigeration pipeline, which rapidly expanded to the insulation wall of the cold storage along the insulation pipe, causing the cold storage fire and the steel structure of the cold storage collapsed. The main body of combustibles is the insulator.

The main causes of fire accidents in cold storage are electric gas welding, cutting operations, short circuits of cable, illegal use of open fire and so on. In 2015, there were 54 cold storage fire accidents, of which 65% were caused by electrical welding, cutting and other operations ;6% were caused by illegal use of open fire ;29% were caused by short circuit of electrical lines ;29% were caused by strong concealment; and 6% were caused by carelessness.

- Failure of refrigeration system

The cause of failure of refrigeration unit can be divided into refrigeration system without reasonable maintenance, often small work, running with disease, after the construction of cold storage, must not ignore, resulting in equipment annual inspection is not up to standard, aging accelerated, Thus occurs the refrigeration system ammonia refrigerant exposure phenomenon. Secondly, the cold storage design project is not perfect, unlicensed design, no professional technology installation construction, some cold storage cost is low, some cold storage construction enterprises choose a large number of defective or second-hand materials, so that the safety of cold storage can not be effectively guaranteed.

Normal use of cold storage fires, insufficient air, inadequate combustion, high carbon monoxide content. The acute lethal concentration of carbon monoxide is only 0.5, colorless and tasteless, and the activity is very strong. If the personal protection of firefighters is not in place, acute poisoning easily occurs. Accordingly, the equipment and facilities of the cold storage should select some mechanical products that meet the requirements of safety certification, such as UL、CSA、ETL、IECEx-CB certification, so as to avoid accidents caused by fire, poisoning and other auxiliary equipment caused by the equipment itself.

CESP explosion-proof linear lamp obtained ATEX/IECEx/UL certification, suitable for Zone1&21,Zone2&22 hazardous areas, can fully meet your advanced explosion-proof requirements. Die cast aluminum shell made of high technology core pulling system is used in the shell. At the same time, the engineer has carried out a special design to improve the heat dissipation effect and make the life of explosion-proof lamps longer, which can reach more than 50000 HRS. Linear explosion-proof light also uses high-quality LEDlm80 lamp beads, while saving energy and environmental protection, but also has strong light-effect lighting. Light reflection cup design, folding 120 degrees.

With the increase of cold storage demand, the requirements for safety are gradually increasing. CESP focuses on the research and development, manufacture and sale of high-quality military patented products, it is a famous manufacturer OEM/ODM explosion-proof lamps in China and a supplier of lighting solutions in hazardous areas.

Description:With the continuous development of the cold chain logistics industry, the number of users who need to build cold storage is increasing. Once anything develops too fast, all kinds of malpractice will gradually emerge. Only in this way can the normal use of cold storage and the personal safety of employees be guaranteed.

Compact 20 Watt Led Tube Lamps T8 Explosion Proof For Cold Storage Food Factory for sale, China LED Tri Proof Lights wholesaler, China LED Tri Proof Lights manufacturer, China LED Tri Proof Lights exporter, China LED Tri Proof Lights company认证

Hazardous Location LED Hand Light CES-SC

- If you need Explosion Proof LED Luminaires for Zone 1 & 21, please click here: (IECEX / ATEX) Explosion Proof LED Luminaires

Hazardous Location LED Linear Lights CES-LN02

Applications:

- CES-LN02 Explosion proof LED linear lights can replace the traditional Explosion proof fluorescent lights for the wastewater treatment, oil and gas refineries, drilling rigs, petrochemical facilities, food and beverage facilities, tunnels, outdoor wall and stanchion mounted Class 1 Division 2, Class II Division 2, Class III hazardous location and general area lighting, and where flammable vapors, gases, ignitable dusts, fibers or flyings are present.

- If you need Explosion Proof LED Line Luminaires for Zone 1 & 21, please click here: (IECEX / ATEX) Explosion Proof LED Line Luminaires

Features:

- Industry-leading efficacy: up to 120LPW;

- CTT: 3000K~6500K

- -40°C to +50°C ambient operating temperature

- Low profile fixture

- Wide optics for uniform illumination

- Fxture warranty

- Entry Size: 3/4’’-14 NPT

Standard Materials:

- Housing –Aluminum alloy (ADC12 and 6063);

- Lens –tempered glass; (The cover is made of 6mm thick tempered glass, which can withstand impacts up to 4J)

Mounting (ordered separately):

Versatile mounting options:

- Ceiling mount

- Wall Mount

- Drop Mount

Mounting Angle:0° to ± 90°;

Exception: When installing models CES-EX-LN-02-150, CES-EX-LN-02-120, CES-EX-LN-02-100, CES-EX-LN-02-80 in ignitable dusts, fibers or flyings, do not allow the lamp cover to be installed upwards.

Certifications and compliances:

- NEC/CEC:

- Class I, Division 2, Groups A, B, C and D

- Class II, Division 2, Groups F and G

- Class III

- T-Class: T *

- Damp and wet locations

- Certification body:UL

- Certification Mark:CUL

- Certificate No:E475887

“*”:

|

Ta Model |

Ambient temperature range |

|||

|

Class I |

Class II and Class III |

|||

|

-40°C ~ 40°C |

-40°C ~ 45°C |

-40°C ~ 50°C |

-40°C ~ 50°C |

|

|

CES-EX-LN-02-150 |

T3C |

T3C |

T3C |

120°C |

|

CES-EX-LN-02-120 |

T4A |

T4A |

T4A |

120°C |

|

CES-EX-LN-02-100 |

T4A |

T4A |

T4A |

120°C |

|

CES-EX-LN-02-80 |

T5 |

T5 |

T4A |

120°C |

|

CES-EX-LN-02-60 |

T4A |

T4A |

T4A |

116°C |

|

CES-EX-LN-02-50 |

T5 |

T4A |

T4A |

116°C |

|

CES-EX-LN-02-40 |

T5 |

T5 |

T4A |

116°C |

Standard :

US: UL 844; UL 1598;

Canada: CSA C22.2 No. 137; CSA C22.2 No. 250.0;

Warning:

CUL for Hazloc:

- SUITABLE FOR WET LOCATIONS;

- THIS LUMINAIRE IS ACCEPTABLE FOR OPERATION IN AMBIENT CONDITIONS NOT EXCEEDING 50 °C;

- FOR SUPPLY CONNECTION, USE WIRES RATED FOR AT LEAST 90°C;

- NO SERVICEABLE PARTS” OR “NO USER SERVICEABLE PARTS. DO NOT OPEN FOR CLEANING.;

- CAUTION - ″TO REDUCE THE RISK OF IGNITION OF HAZARDOUS ATMOSPHERES, DISCONNECT THE LUMINAIRE FROM THE SUPPLY CIRCUIT BEFORE OPENING. KEEP TIGHTLY CLOSED WHEN IN OPERATION.″;

- THIS PRODUCT MUST BE INSTALLED IN ACCORDANCE WITH THE APPLICABLE INSTALLATION CODE BY A PERSON FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF THE PRODUCT AND THE HAZARDS INVOLVED;

- “CAUTION – RISK OF SHOCK” and “DISCONNECT POWER BEFORE SERVICING”.

Technical table:

|

Model |

Power (W) |

Input voltage: AC100-277V; Frequency: 50/60Hz; |

|||||

|

CCT:3000K~6500K |

|||||||

|

Power factor:0.97 |

|||||||

|

Luminous flux (LM) |

Light efficiency (Lm/W) |

LEDs Chip |

LEDs Type |

Power Model |

Weights (kg) |

||

|

CES-EX-LN-02-40 |

40 |

4800 |

120 |

72PCS |

2835(3V) |

HLG-60H-36A |

7.5 |

|

CES-EX-LN-02-50 |

50 |

6000 |

120 |

72PCS |

2835(3V) |

||

|

CES-EX-LN-02-60 |

60 |

7200 |

120 |

72PCS |

2835(3V) |

||

|

CES-EX-LN-02-80 |

80 |

9600 |

120 |

144PCS |

3030 (6V) |

HLG-150H-36A |

10.6 |

|

CES-EX-LN-02-100 |

100 |

12000 |

120 |

144PCS |

3030 (6V) |

||

|

CES-EX-LN-02-120 |

120 |

14400 |

120 |

144PCS |

3030 (6V) |

||

|

CES-EX-LN-02-150 |

150 |

18000 |

120 |

144PCS |

3030 (6V) |

||

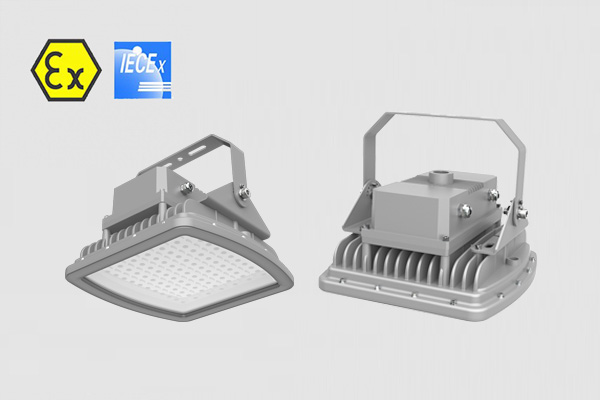

Dimensions:

Figure 1 applies to Models CES-EX-LN-02-40, CES-EX-LN-02-50, CES-EX-LN-02-60 Explosion proof LED Linear Light

L x W x H: 596 mm x 126 mm x 114mm

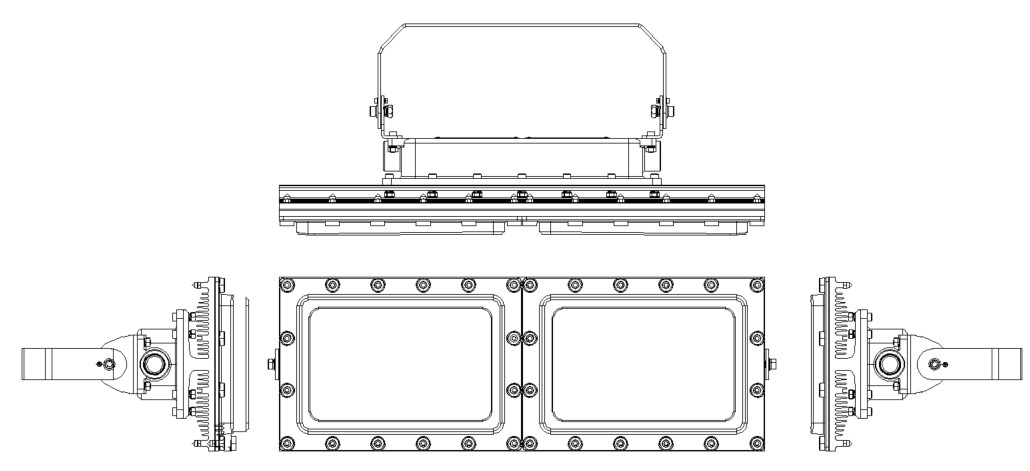

Figure 2 applies to models CES-EX-LN-02-80, CES-EX-LN-02-100, CES-EX-LN-02-120, CES-EX-LN-02-150 Explosion proof LED Linear Lights

L x W x H: 564 mm x 202mm x 112mm

According to the operating pressure

Fire hazard analysis of distillation units

According to the operating pressure, can be divided into atmospheric distillation, vacuum distillation (for high boiling point, difficult to volatilize or high temperature distillation can cause decomposition, explosion, polymerization and other heat sensitive substances mixture, decompression can reduce the boiling point of materials, thereby reducing the distillation temperature, increase safety, such as nitrotoluene decomposition explosion at high temperature, styrene easy to polymerize at high temperature; also can be used for highly toxic materials distillation to prevent leakage into the air), pressurized distillation (for atmospheric pressure gas system).

- Method of distillation

(1) According to the continuity of production, it can be divided into continuous distillation and intermittent distillation.

(2) According to the operation mode, it can be divided into no reflux and reflux distillation; among them, no reflux is divided into simple distillation and equilibrium distillation, and reflux distillation is called distillation; distillation can be divided into general distillation and azeotropic distillation, extractive distillation, steam distillation and so on.

- Composition of distillation

A complete distillation system is generally composed of a distillation tower, reboiler, condensing cooler, reflux tube, material pump, product storage tank, etc., or maybe a combination of two or more of them. Simple distillation system is usually composed of a distillation kettle and its heating device, condensing cooler and receiving tank. The heating device of kettle distillation has the jacket type outside the kettle, the inner coil type of the kettle, and some materials also adopt the direct fire heating type or electric heating type outside the kettle.

- Brief process flow

Take the atmospheric and vacuum equipment in petroleum refining as an example to carry on the risk analysis. According to the characteristics of the production process, The technology uses atmospheric and vacuum distillation, The fractionator has two side lines, The first line (about 157℃) is distilled and heated to 90℃ by pump and feedstock, Combined with the second line, cooled to 45℃, As a fuel oil 2#(heavy diesel) outlet device; The second line (about 259℃) was distilled and heat transferred to 94℃ by pump and feedstock, Combined with the front line, cooled to 45℃, As a fuel oil 2#(heavy diesel) outlet device. stripping tower (I): stripping tray 10 layers, operating temperature 175℃, Operating pressure 0.1 MPa; stripping tower (II):6-layer stripping tray, Operating temperature 260℃, Operating pressure 0.1 MPa.

- Analysis of the fire and explosion hazard of atmospheric and vacuum distillation units

- materials and products are fire and explosion hazards

Most of the raw materials, intermediates and products in the process of atmospheric and vacuum distillation of petroleum refining belong to fire dangerous goods, in which crude oil and light oil are flammable, explosive, easy to evaporate, and have flammable gas, which will explode when the source of fire occurs.

- danger of electric desalination dehydration

In the process of electric desalination and dehydration, there is high temperature hot oil, electric device with high voltage electric field, if the desalination tank is not filled with raw oil or air, start high voltage power supply; Or high-voltage electrical insulation or high electric field strength insulation breakdown, will lead to fire and explosion.

The overpressure of the electric desalination dehydration tank and the untimely unloading of the safety valve lead to the leakage of the pipeline and flange connection of the desalination dehydration tank, the loss of the raw material oil, and the fire and explosion accident caused by the ignition source.

The crude oil is operated in the electric desalination tank with a temperature of 130~145℃ and a pressure of 0.9~1.2 MPa. In addition, the runaway interface in the tank can easily cause oil with water or water with oil, bring fluctuations to production and threaten safety. The composition of crude oil is complex. If the water content of the inlet device is too large, it is easy to cause dehydration of the electric desalination tank, and a large amount of water enters the heat transfer system and tower, which can cause overpressure oil leakage of the equipment and take off the safety valve of the atmospheric pressure tower when it is serious.

- Fire hazard in distilled parts

operation temperature of the system is high, the high temperature is above 400℃, the medium is flammable and explosive. If the equipment failure or aging, or human factors such as illegal operation, misoperation caused by leakage, open fire or high heat fire and explosion risk. In addition, the cold exchange equipment in the device has a pressure difference between the tube side and the shell side. Once the phenomenon of high pressure channeling and low pressure occurs, the low pressure part will crack, resulting in material leakage, thus causing fire and explosion accidents.

In the process of distillation, because of the boiling state, the system always presents a gas-liquid coexistence state. If the material leaks out or inhales air because of equipment rupture or operation error, or because of condensation and insufficient cooling, a large amount of steam escapes through the storage tank and other parts, explosive gas mixture can be formed.

Due to the increase of sulfur content, the properties of feedstock oil change, the ammonia injection is not changed at the top of fractionator, and the corrosion phenomenon in the top oil and gas line, top circulation line and cold exchange system HCI-H2S-H2O fractionator increases to varying degrees, speeding up the corrosion of equipment and causing leakage accident due to corrosion, thus causing fire and explosion accident.

- readily form explosive gas mixtures

In the process of distillation, because of the boiling state, the gas-liquid coexistence state is always present in the system. If the material leaks out or inhales air due to equipment rupture or operation error, or because of condensation and insufficient cooling, a large amount of steam escapes through the storage tank and other parts, explosive gas mixture can be formed, and explosion combustion in or out of the container will occur in the ignition source. For example, before the shutdown and maintenance of a refinery decompression tower, due to the elimination of too fast vacuum, the oil and gas in the tower is very thick, the temperature is very high, the air is inhaled by the emptying valve in large quantities, resulting in an explosion accident, and the 10-story tray in the tower is blown off.

- prone to spontaneous combustion

The spontaneous combustion point of crude oil and petroleum distillate is low, such as 255~390℃ of gasoline ,350 380℃ of diesel oil and 350℃ of crude oil, while the temperature of oil in distillation unit is between 220 and 395℃.

- Complex and dangerous distillation process

Distillation operation is a complex process. There are many auxiliary equipments in distillation column, such as feed pump, heated reboiler, gas condensate cooler, reflux tube and receiving tank, side line discharge (including multiple side line discharge), top discharge, bottom discharge system, etc. For example, the distillation control temperature is too high, it is easy to appear the danger of overpressure explosion, blanking, overheating decomposition and spontaneous combustion, and even make the operation out of control and cause explosion; if the temperature is too low, there is the danger of flooding tower. For tower distillation, the amount of gasification can be increased, and uncondensed steam can enter the receiving tank, resulting in an overpressure explosion of the tank. The increase of reflux in operation will not only reduce the operating temperature in the system, but also lead to flooding towers and be out of control. The outlet pipe of distillation equipment is condensed and blocked, which will cause the pressure in the equipment to rise and explode in fire. In high temperature distillation equipment, if cold water or other low boiling point substances enter, a large amount of gasification will occur in an instant, and an explosion fire will occur due to the sudden rise of internal pressure.

- Heating systems are dangerous

The raw material should be heated to 400℃ by heating furnace before entering the decompression tower, and the furnace temperature can reach more than 700℃. If the operation of the heating furnace is improper, the flow rate of the feedstock oil in the furnace tube is too low, the residence time is too long or the temperature is too high, it will crack and coking in the furnace tube, make the furnace tube blocked and the heat conduction poor cause local overheating, lead to the leakage of the material in the furnace tube and cause the fire and explosion accident. Improper selection of furnace tube materials and serious wear and corrosion may lead to perforation, rupture or leakage of furnace tube, resulting in leakage of material in furnace tube and fire and explosion accident.

The valve, flange, gasket and so on on the outlet line of the furnace pipe cannot appear the problem, otherwise once the leakage may occur the fire. Furnace fuel can not leak, if gas leakage to the outside and air mixed to form explosive gas, heating furnace with open fire will occur deflagration. If the furnace flamenze occurs, attention should be paid to steaming the residual gas to avoid a furnace explosion.

In the starting stage of the device, the oven should be carried out to remove moisture and inspect the equipment. If the ignition temperature is not strictly operated in accordance with the rules and heating curves, it will be easy to occur equipment accidents and explosion accidents.

- equipment, pipelines vulnerable

Equipment, pipeline and so on in the long time repeated pressure and material high-speed flow, friction process, metal shell materials are prone to metal fatigue. Operation under high temperature conditions causes temperature difference stress failure and high temperature creep rupture. Tall towers and pipes are vulnerable to deformation cracks caused by additional stress such as vibration, wind, foundation sinking and external loads. Acidic in the treatment of crude oil with high sulfur content in corrosive media such as petroleum distillation

Sulfur compounds, with strong corrosion, in the pressure relief tower bottom pump outlet high temperature pipeline, atmospheric pressure tower top oil and gas volatile line, air cooler gas, liquid phase change and other parts, prone to corrosion perforation, wall thickness thinning, and then lose bearing capacity or leakage, resulting in fire.

- ignition source in the process

In order to meet the distillation requirement of oil, the temperature of the furnace chamber is very high, and the furnace is easy to become the ignition source of combustible material. Atmospheric distillation unit uses more electricity, there are distribution rooms, a large number of motors, wires, switches, control instruments, among which there is no explosion-proof or can not meet the requirements of explosion-proof grade, the generation of electric sparks or short circuit may form a source of ignition.

The high speed flow of oil in the pipeline will produce static electricity and easily accumulate, the highest electrostatic voltage can reach more than ten thousand volts, if the static electricity can not be removed in time, it may discharge to produce electric spark. During thunderstorms, if combustible gas is discharged from the top of the distillation tower, it may cause a lightning strike to catch fire. Before the equipment pipeline overhaul, the system does not carry on the thorough replacement, the cleaning, before the gas analysis qualified, carries on the fire, the overhaul operation, has the fire explosion danger.

- Technical Measures for Fire Protection and Explosion Protection

- prevent the formation of explosive mixtures

When the electric desalination dehydrator starts, the air in the tank should be drained, and then the high voltage should be connected after filling the oil, so as to avoid the explosion of the mixture of oil and gas in the tank caused by the electric spark. High voltage electrical appliances should be regularly checked, maintenance: found poor insulation or high electric field strength should stop using, to prevent the production of electric sparks.

The distillation system should strictly carry out air tightness and wind resistance inspections to ensure its airtight. When the vacuum distillation is in normal production, the flanges and emptying valves connected with the tower should be tight to prevent the formation of explosive gas in the air suction tower. After distillation, we should pay attention to the correct elimination of vacuum. When the temperature in the tower is cooled below 200℃, the vacuum in the tower can be eliminated slowly.

- operate in strict accordance with regulations

In distillation operation, not only the operating parameters such as temperature, pressure, feed quantity, reflux and so on are strictly controlled, but also the mutual restriction and mutual influence between them should be paid attention to. Automatic control systems and safety instrument systems should be used as much as possible to reduce human errors.

When steam is heated, the opening degree of the control valve should be suitable to prevent the material from evaporating sharply, and a large amount of steam cannot be discharged to increase the pressure and cause the equipment to burst. In operation, we should always pay attention to keep the distillation system unobstructed, prevent the pipe from clogging, pressure rise, and cause danger. To avoid the low boiling and water entering the high temperature distillation system, the condensed water in the tower and its auxiliary equipment must be released before the high temperature distillation system starts, so as to prevent the sudden contact with the high temperature material from vaporizing and pressurizing and causing the spray or explosion.

- Anti-corrosion Measures

Distillation equipment and pipes should meet the requirements of safe production in material and design. Reasonable flow rate and necessary corrosion margin can be used to avoid 90℃ of quick turning elbows on the oil transfer line, select suitable corrosion resistant materials, coatings and wear-resistant liners, adopt anode protection and cathodic protection, and take process anticorrosion measures, such as sulfur containing materials to be treated before entering distillation equipment, use neutralizer and corrosion inhibitor, etc.

- Inspection and maintenance of reinforcing devices

It is found that the equipment breakage should be repaired in time, the instruments, instruments, equipment containers, pipelines and so on should be replaced regularly, and the equipment running with disease, overdue service and overload operation should be resolutely eliminated.

Heating furnaces must be strengthened maintenance, each overhaul must measure the thickness of the pipe wall, cleaning furnace coke removal. If the furnace is old and the pipe is denuded seriously, it should be updated.

- Installation of safety devices and fire fighting facilities

Desalination dehydration tank should be installed blackout, stop pump, oil leakage alarm device, and pay attention to check its use.

Distillation equipment should have a complete temperature, pressure, and flow meter device. Vacuum distillation pumps should be equipped with a one-way valve to prevent the sudden stop of air into the equipment. Pressure distillation equipment should be provided with a safe discharge device. Heating furnaces should be equipped with explosion doors, so that explosions can be a timely pressure relief. The system should be equipped with emergency emptying pipes and other safety devices to ensure the rapid discharge of materials in the reactor and prevent explosion accidents. The exhaust pipe of the system shall be connected to the torch system, and the fire arrester shall be installed on the pipe.

The electrical equipment of the atmospheric and vacuum distillation unit must be explosion-proof and well grounded. Fixed flammable gas leakage monitoring alarm should be installed in the installation area and tank area to detect oil and gas leakage in time.

The heating furnace, distillation tower and stripping tower should be equipped with steam fire extinguishing facilities, and the foam fire extinguishing system should be installed in the device. The control valve should be located in a convenient place to ensure that the device can quickly and timely control its spread and expansion once the fire occurs.

- Strengthening Fire and Explosion-proof Safety Management

There are more pressure vessels in the pretreatment device, and there is the danger of overpressure explosions. When the pressure vessel overpressure ruptures, the energy released by the expansion of gas or high temperature material causes the vessel to crack further and causes the vessel debris to fly around at a higher speed, resulting in casualties or property losses. At the same time, flammable and explosive materials or high temperature materials leaking from container explosions will cause fire and explosion in case of ignition source.

Formulate sound rules and regulations for fire safety production, responsibility system, electricity and fire use system, and effective and perfect emergency handling rules, establish and formulate strong fire safety supervision, inspection and inspection, system, timely detection of hidden dangers of accidents, control unsafe factors.

Distillation, if the equipment failure or aging, or human factors such as illegal operation, misoperation caused by leakage, open fire or high heat fire and explosion risk. In serious cases, explosive gas mixture can be formed if the material leaks out or inhales air due to equipment rupture or operation error, or if a large amount of steam escapes through the storage tank due to insufficient condensation and cooling, and explosion combustion in or out of the container will occur in case of ignition source. Therefore, distillation of the selected equipment is due to careful consideration.

Shenzhen CESP Co.,Ltd. focus on the field of special industrial lighting is a design, development, production and sales of high-tech enterprises, complete management team for the domestic power, metallurgy, railway, large industrial and mining enterprises, marine ships and other lighting areas to provide professional lighting solutions, but also for international well-known enterprises to provide advanced technical support and product supporting services.

CES-EX-SF is an increased safety and dustproof explosion-proof lamp, Has ATEX IECEX Certification standards, Is a low installation height of indoor lighting waterproof grade IP66 explosion-proof lamps. During use, the maximum temperature of this explosion-proof lamp is about T80℃, It does not cause explosions or ignition of other equipment. Which he can use in a general environment of -20 C ~40 C, The shell is a flame retardant, f1- UV resistant PC shell, Can withstand four J of shock, Very suitable for distillation environment. His luminous angle is about 100, Is a light efficiency in 120~140 lm/W of high-quality lamps, With a variety of shell shapes, Such as rectangle, square, oval, etc, If you need it, You can contact us for further consultation, Or you have an explosion - proof lighting problem, You can also contact to provide you with a solution.

Hazardous Location LED Floodlight CES-J Series

Explosion proof LED Hand Light CES-EX-SF Series

Explosion proof LED Hand Light CES-EX-SC

- If you need Class I Division 1 Explosion proof LED hand light, please visit here Explosion-proof LED Hand Lights CES-SC