ATEX Explosion Proof Flexible LED Strip Light - Zone 1 Zone 21

The CES-EX-LP Explosion Proof LED Strip is an innovative range of LED hazardous area lighting products. This series is specifically designed for environments with potentially explosive gases and dust, providing reliable and safe lighting solutions for equipment areas, offering both continuous area illumination and directional lighting. Constructed with flexible and durable silicone material, equipped with waterproof connectors and external explosion-proof boxes, it is tailored for hazardous area lighting. The LP series explosion-proof strip light comply with Zone 1, Zone 21, Zone 2, and Zone 22 standards, and have obtained ATEX certification.

CES-EX-LP LED explosion-proof strip light produce luminous efficacy of up to 90 LM/WTheir flexibility and excellent sealing properties result in a protection rating of up to IP67, providing limited dust protection and basic splash water protection. These light bars are weather-resistant, suitable for indoor and outdoor applications, particularly ideal for areas exposed to frequent moisture or dust.

Applications include but are not limited to wastewater treatment plants, oil and natural gas refineries, drilling rigs, petrochemical facilities, food and beverage facilities, tunnels, outdoor or indoor auxiliary lighting installations, and areas with flammable vapors, gases, combustible dust, fibers, or splashes. Suitable for hazardous locations in Zone 1/21 and 2/22, with explosive gas environments.

Installation options include two choices:

- Fixed installation: Utilizes installation accessories made of 316L stainless steel, corrosion-resistant, suitable for industrial workplaces with hazardous gases or dust.

- Suspension installation: Uses steel wire ropes and 316 stainless steel fittings, with adjustable height, suitable for tunnels, bridges, and similar locations.

Features

- Industry-leading efficacy: 90lm/W ±5

- LED Type: 2835

- Power: 10W/meter, 12W/meter

- Input voltage: DC 24V / DC 36V / DC 48V

- Color: Cool white / Warm white

- CCT: 2700K, 3000K, 3500K, 4000K, 5000K, 6000K

- Operating temperature: -40℃ - +80℃

- Protection grade: IP65 / IP67

- Material: Environmentally friendly silicone materia

- Environment: anti-explosive, anti-corrosion, flame retardant resistance, UV resistance

- Beam angle:120°

- Weight: 285g/Meter

Certificate & Standard

Have certified CES-EX-LP Strip Light with the ATEX standards for hazardous location and environments.

ATEX Standard:

- EX II 2G Ex mb op is IIC T4 Gb

- EX II 2D Ex mb op is IIIC T135°C Db

- Certificate NO.: TUV IT 24 ATEX 0179 X

Standard:

-

EN IEC 60079-0

-

EN IEC 60079-18

-

EN IEC 60079-28

LED Explosion-proof Lights Applied in Italian Mine Refuge Chambers

Our cutting-edge LED explosion-proof lights have achieved success in Italian mine refuge chambers! With compliance to the EU ATEX explosion-proof certification, we ensure our products are safe and reliable in extreme environments. Efficient, energy-saving, explosion-proof design, and durability make it the top choice in the mining industry. Choose our lights for a higher level of mining safety!

【Image attached: Real-world showcase of our LED explosion-proof lights in mine refuge chambers. The final image of the refuge chamber is sourced from the internet and is for viewing purposes only to understand the concept of a refuge chamber.】

Choosing CES-J40s is not just opting for bright illumination but prioritizing safety. In the balance between brightness and security, the CES-J 40W series stands out as the preferred choice for the chemical storage facility in the Middle East.

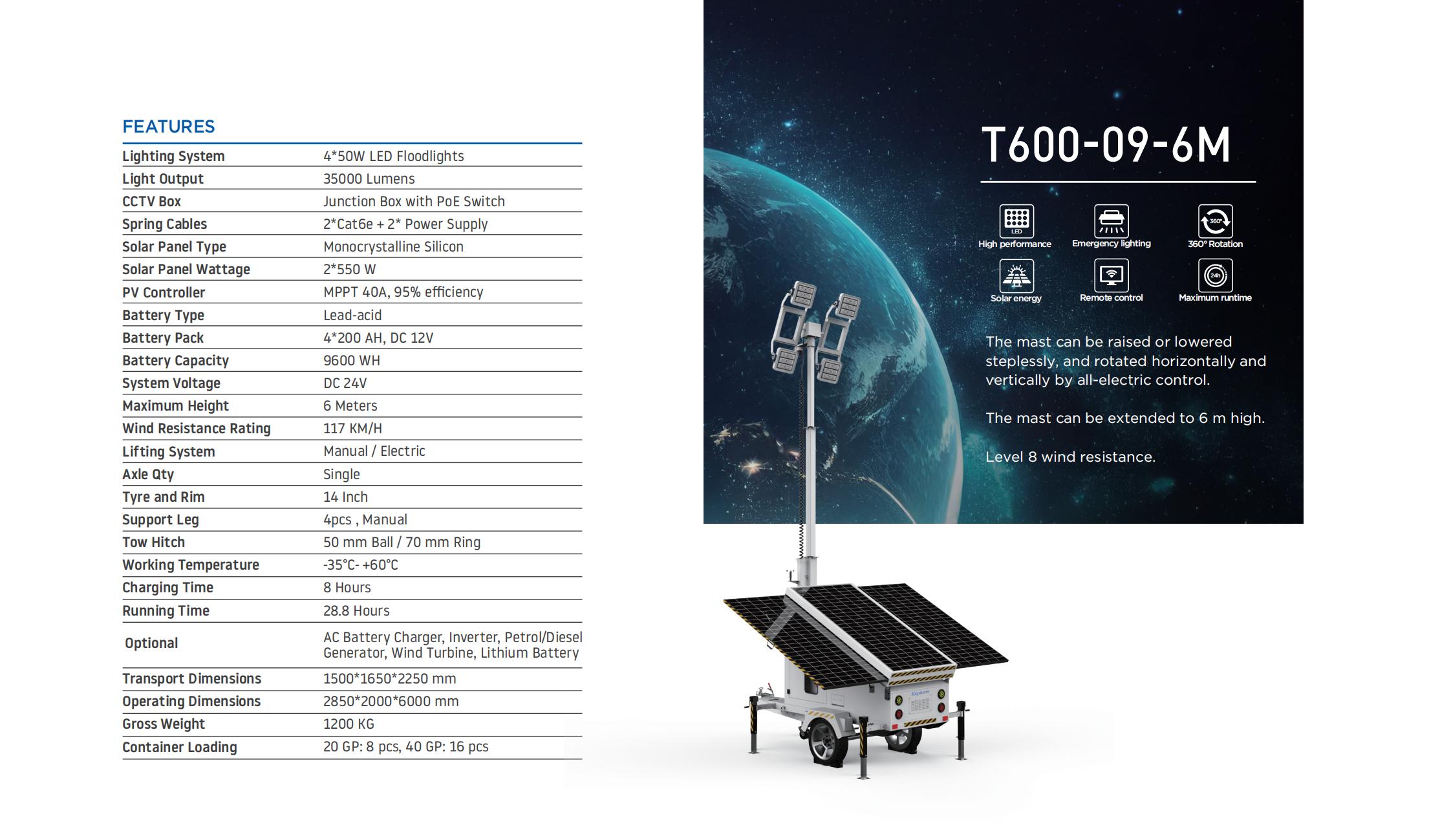

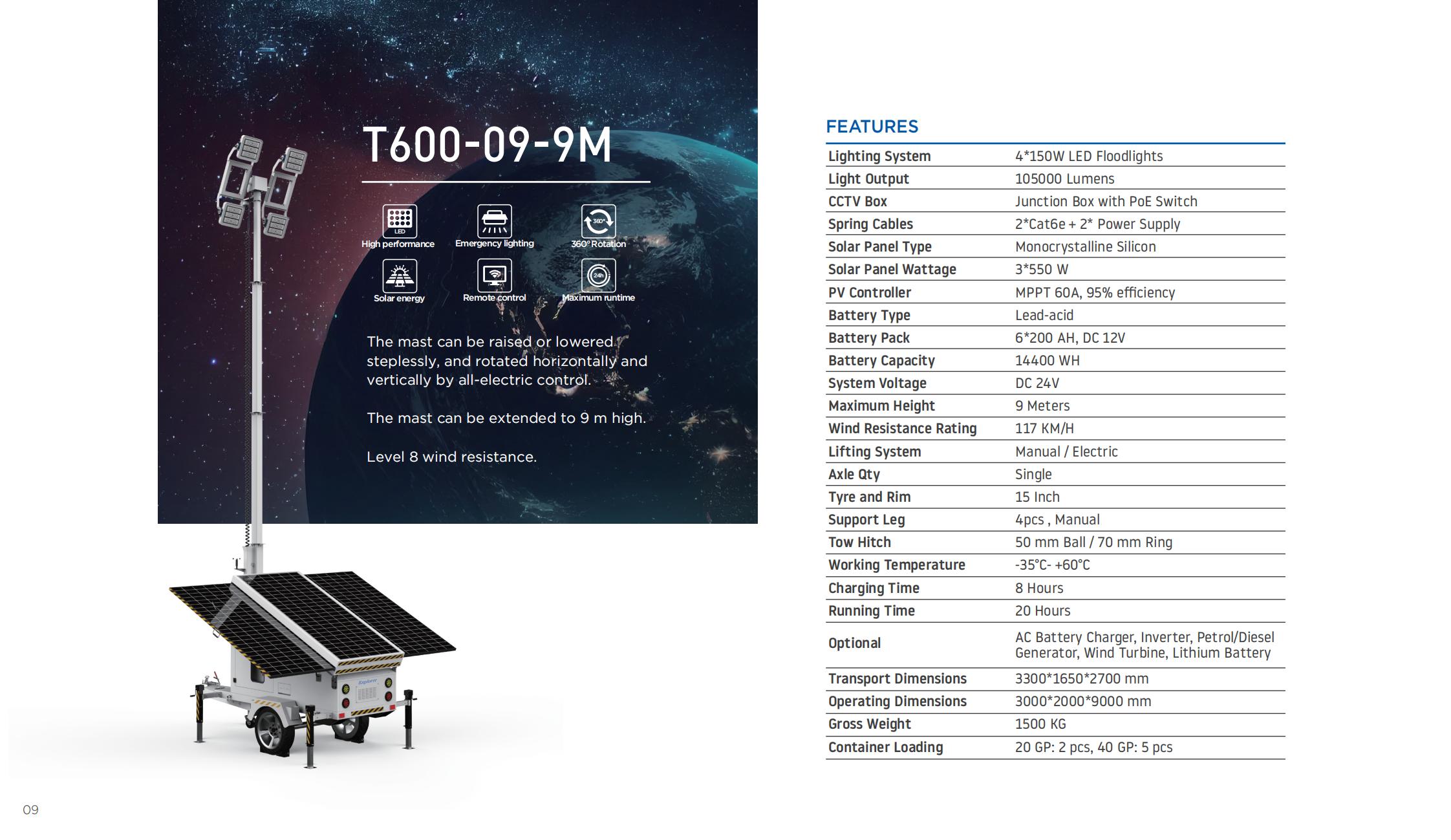

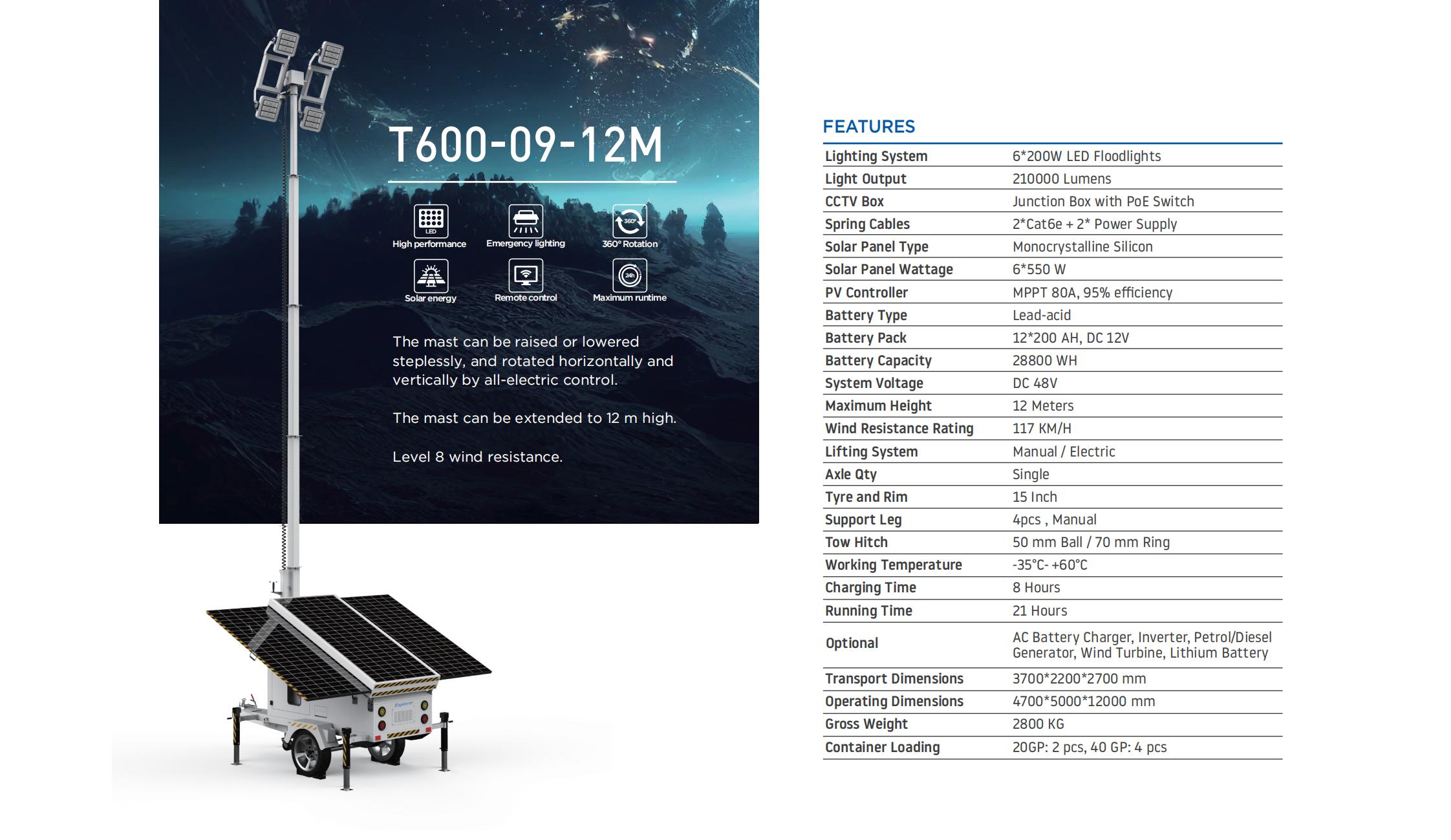

Mobile Solar Lighting Tower 200W/600W/1200W (Solar Panel)

Mobile Solar Lighting Tower 200W/600W/1200W (Solar Panel) (Solar Panel)

DESCRIPTION

Introducing the CES-SW Series—a meticulously crafted solar lighting tower designed to excel in emergency illumination scenarios. Tailored for a wide range of applications, including large construction projects, mining operations, maintenance and repair tasks, accident handling, flood prevention and rescue, disaster relief, and more. This state-of-the-art lighting solution features high-performance LED floodlights that optimize the efficiency of both the battery pack and the entire system. The LED floodlights offer the flexibility of manual or automatic adjustment, while the 360° rotation capability ensures comprehensive lighting coverage.

Capable of powering LED floodlights for up to 24 hours on a single full charge, the CES-SW Series stands as a dependable source of illumination. In emergencies, quick recharging with mains is possible. Supporting 100-220Vac /50-60Hz output and equipped with a deep cycle gel battery, the system ensures reliability and durability across various applications. Illuminate your surroundings efficiently and sustainably with the CES-SW Series solar lighting tower.

FEATURES

Mobile and Powerful:

A single full charge powers the LED floodlights for up to 24 hours, illuminating an extensive area of up to 300m².

Solar Powered:

Utilizes renowned solar solutions, featuring brand-name (such as LONGi) single-crystal silicon 550W module power with a remarkable efficiency of 21.7%.

LED Floodlights:

Allows manual or automatic adjustment of LED floodlights (Ex or not), with a 360° rotation for comprehensive lighting coverage. The mast is extendable and retractable.

Mast:

An electric mast with customizable heights of 6M, 9M, or 12M, providing stability with Level 8 wind resistance.

Battery:

Supports 100-220Vac/50-60Hz output, offering power for construction equipment, mobile phones, and small electrical appliances. Utilizes a reliable and durable deep-cycle gel battery.

APPLICATIONS

The CES-SW Series is well-suited for a variety of applications, ensuring versatile performance across different scenarios:

- Large Construction Projects: Illuminate expansive construction sites for enhanced visibility and safety.

- Mining Operations: Provide reliable lighting for efficient operations and safety measures in mining environments.

- Maintenance & Repair: Facilitate well-lit workspaces for maintenance and repair tasks, ensuring precision and safety.

- Accident Handling: Quickly respond to accidents with well-lit areas for effective and safe handling.

- Flood Prevention & Rescue: Enhance flood prevention efforts and facilitate rescue operations in challenging conditions.

- Disaster Relief: Illuminate disaster-stricken areas during relief efforts, providing critical visibility for aid distribution and rescue operations.

CES-J40s — The Secure Explosion-Proof Panel Light Replacement for a Chemical Storage Facility in the Middle East.

The chemical storage facility project in the Middle East involves hazardous substances such as DEGRESSING chemicals, SULPHURIC Acid, SEPARATING solutions, and CHROMIC Acid, among others. To ensure safe operation in this high-risk environment, our CES-J40s LED explosion-proof lights hold IECEx and ATEX Zone 1 explosion-proof certificates, providing a reliable lighting solution and minimizing potential safety risks.

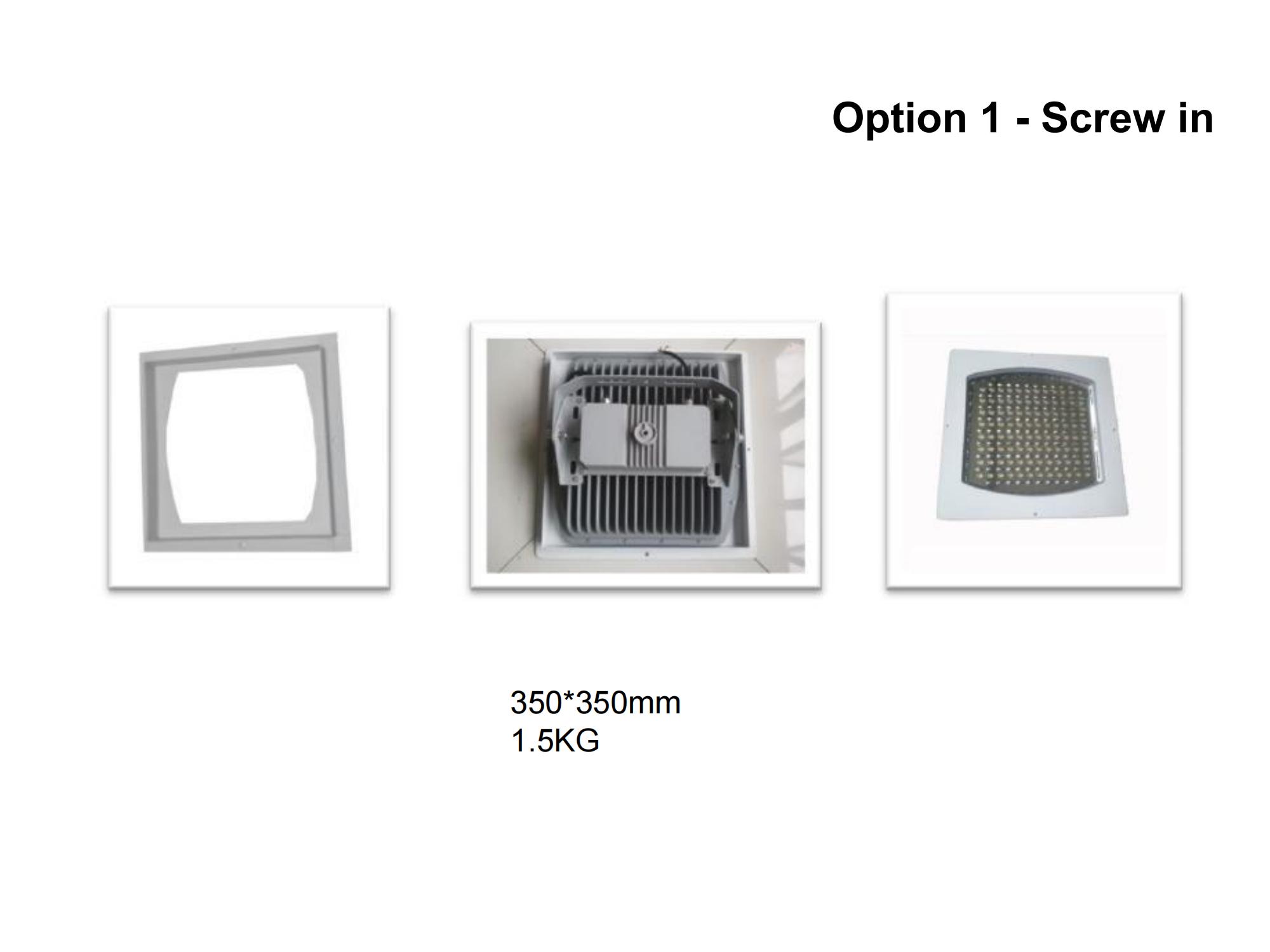

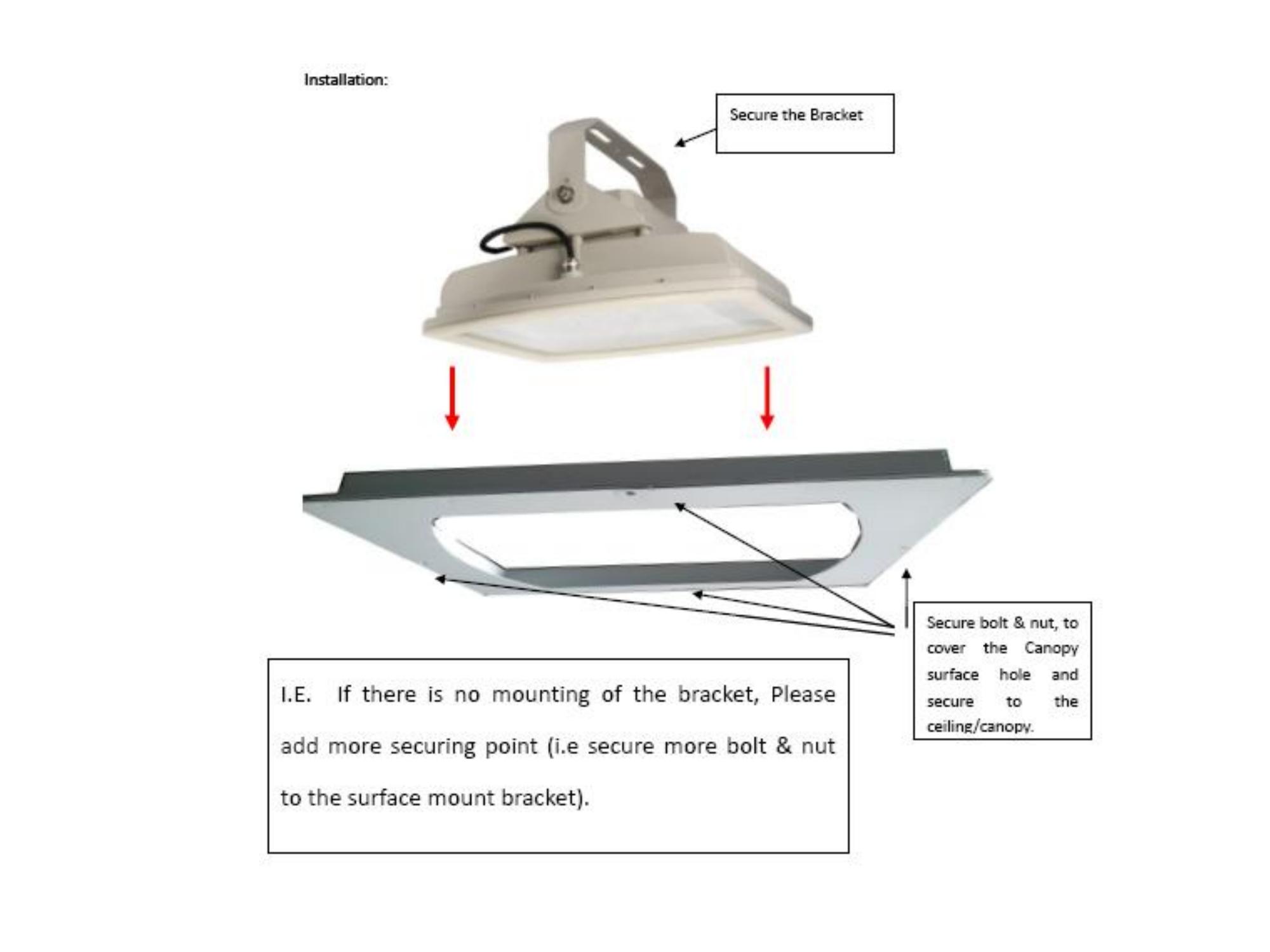

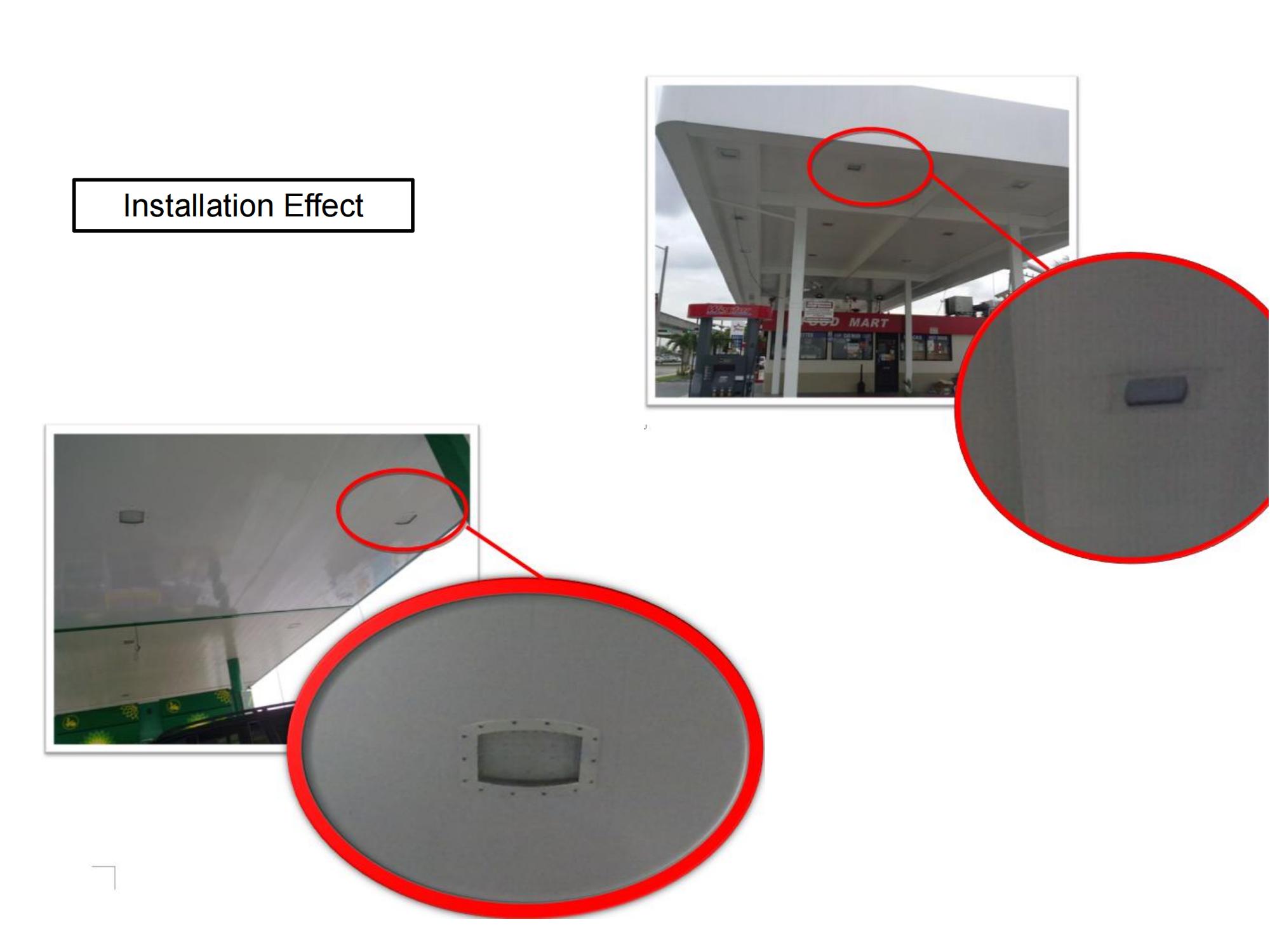

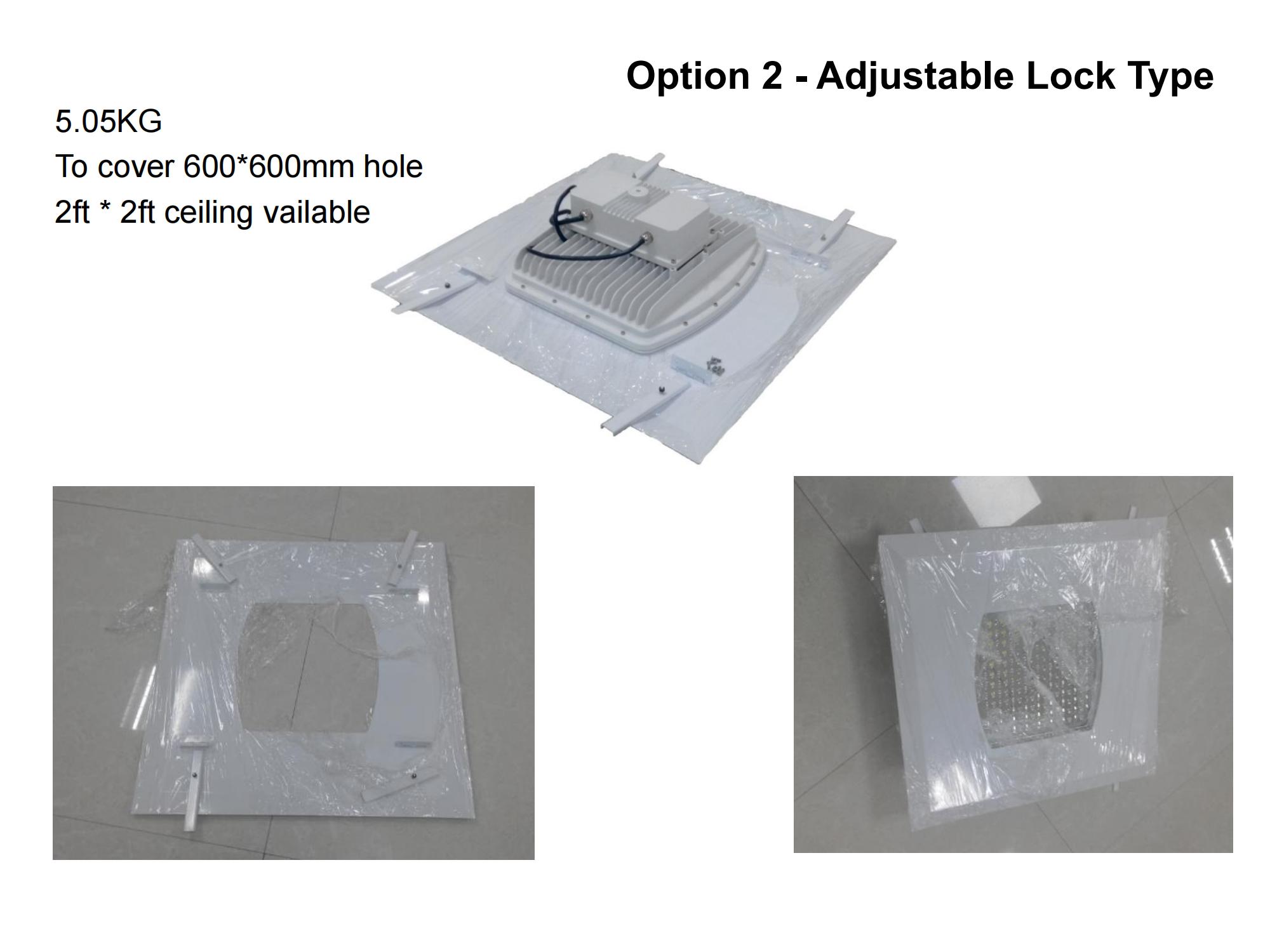

The CES-J40s series not only excels in safety performance but also introduces an innovative embedded installation approach, effectively meeting the requirements of a 2ft*2ft ceiling installation. This design ensures a compact installation and achieves efficient lighting similar to panel lights.

Choosing CES-J40s is not just opting for bright illumination but prioritizing safety. In the balance between brightness and security, the CES-J 40W series stands out as the preferred choice for the chemical storage facility in the Middle East.

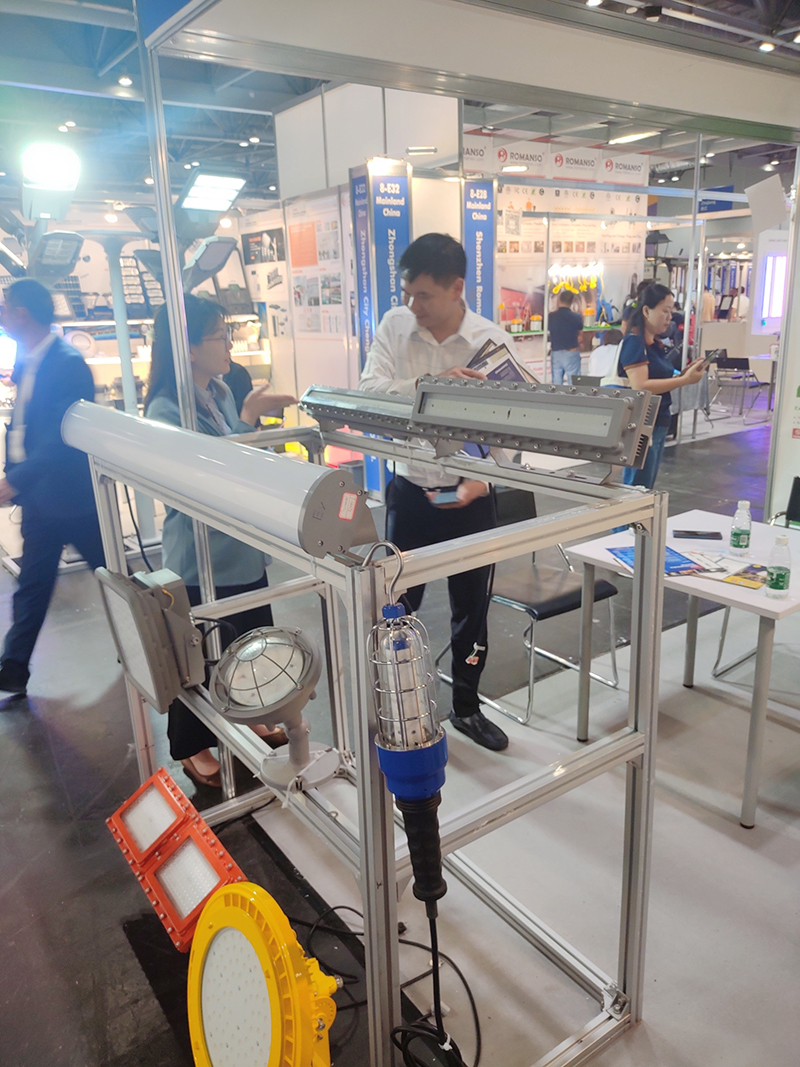

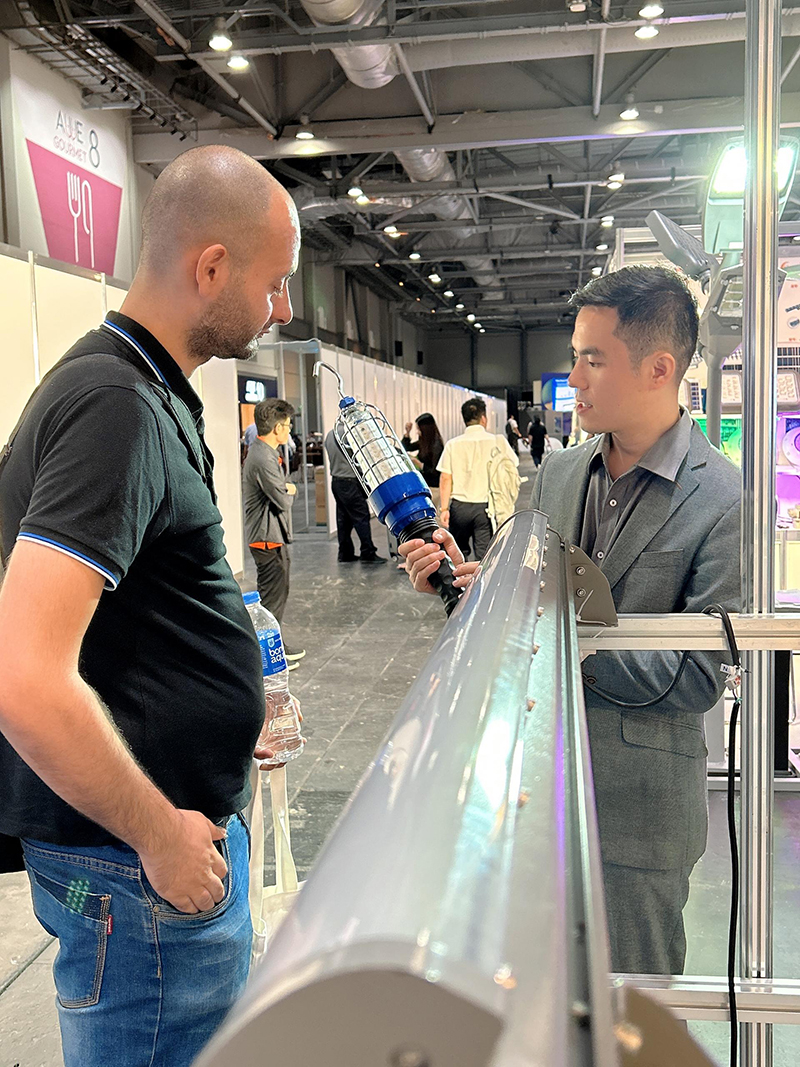

Gratitude and Anticipation: Hong Kong International Outdoor and Tech Light Expo 2023

Hong Kong, October 29, 2023 — With the successful conclusion of the Hong Kong Outdoor and Technology Lighting Expo, we wholeheartedly thank all our esteemed customers who attended this event. Your participation and support made this occasion even more exciting and successful.

This expo provided us with an excellent opportunity to meet, engage, and share with our customers. It was a grand showcase of our high-quality products and exceptional services.

We will continue to work tirelessly, dedicated to delivering higher quality products and superior services. We deeply understand your expectations and requirements, and we are committed to meeting your needs to ensure that our partnership becomes even more successful and enduring.

Once again, thank you for attending this expo. We look forward to future collaborations and the creation of a brighter tomorrow together. If you have any questions or potential collaboration ideas, please feel free to contact us. We will do our utmost to meet your requirements.

Thank you for your support, and we anticipate our future meetings with you!

Sincerely,

CESP Team

Oct 30th, 2023

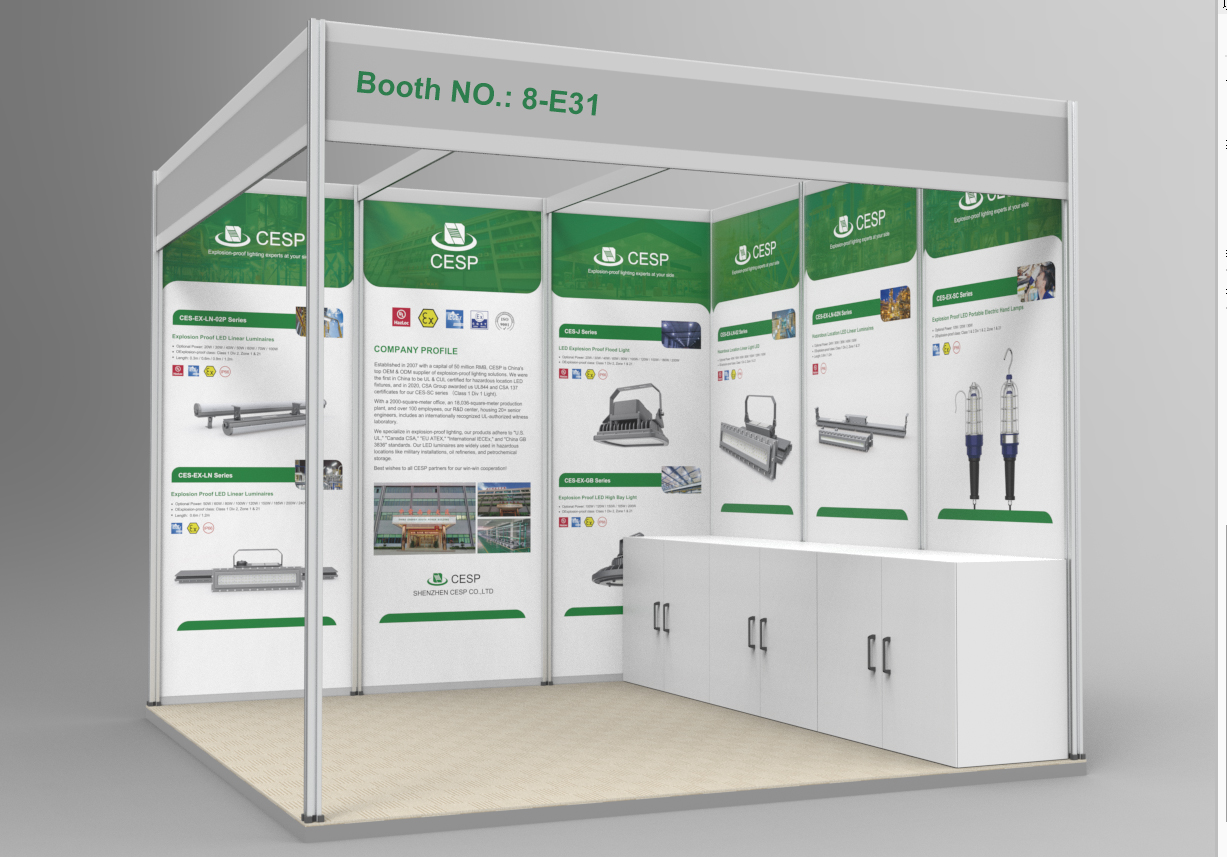

Invitation to Visit Our Booth at the Hong Kong International Outdoor and Tech Light Expo

Dear Client,

We are delighted to extend a warm invitation for you to visit our booth, NO. 8-E31, at the Hong Kong International Outdoor and Tech Light Expo, taking place from October 26th to October 29th, 2023.

As a leading company in the industry, we will showcase our latest and most advanced explosion-proof lighting solutions tailored to meet various illumination needs. Our pride lies not only in the technological advancements of our products but also in their design and reliability, ensuring we provide you with safe, efficient, and innovative lighting solutions.

This expo presents a rare opportunity to show you products firsthand and engage with our professional team. You will gain insights into our latest technological developments and learn how we continuously strive for innovation to meet the diverse needs of our valued clients.

Please make arrangements to attend our booth at 8-E31 during the expo dates. If you require additional information or have specific requests, feel free to contact us.

Thank you for your attention and support. We anticipate meeting you at the expo!

Best regards,

CESP Team

240W - 380W Explosion-Proof Flood Light Fixtures

ATEX Explosion Proof LED Flood Light - 240W 300W 350W 380W

The CES-EX-D-JX Series are explosion-proof LED floodlights designed for use in hazardous locations, specifically Zone 1 and Zone 2 areas. Similar to the previous product you mentioned, these lights are also ATEX-approved, indicating their suitability for use in potentially explosive atmospheres.

Explosion-Proof Design: These LED floodlights are designed to prevent the ignition of hazardous gases, vapors, or dust in the surrounding environment, making them safe for use in areas where explosive materials may be present.

Various Wattage Options: The series offers a range of wattage options, including 300W, 350W and 400W. This flexibility allows you to select the appropriate level of illumination based on your specific requirements.

ATEX Approved: The ATEX approval is crucial, as it confirms that the lights meet the safety standards required for operation in potentially explosive atmospheres.

Features

- -40°C to +40°C/50°C/60°C ambient temperature

- Wide optics for uniform illumination

- 5 years warranty

- Housing – Aluminum alloy (ADC12)

- Lens – tempered glass

- Weight: 19.6KG

Parameters

- Power: 240W 300W 350W 380W

- Input voltage: AC110-277V, 50/60Hz

- Power factor: 0.97

- Light efficacy: 130lm/W

- CCT: 3000K/4000K/5000K/5700K/6500K

- LEDs: 3030

- LED Driver: High-Efficiency Driver

Certificate & Standard

Certifications and compliances for hazardous location.

-

CNEX Certificate No. : CMExC23.1137

• Ex db IIC T6 Gb;

• Ex tb IIIC T80°C Db;

• IP66; -

ATEX Certificate No. TUV CY 24 ATEX 0206973 X

• Ex ll 2G Ex db op is IC T6…T4 Gb

• Ex II 2D Ex op is tb IIIC T130 ℃Db

Mounting

Versatile mounting options:

- Pendant mount

- Pole mount

- Wall mount

120W - 200W Explosion-Proof Flood Light Fixtures

ATEX Explosion Proof LED Flood Light - 120W 150W 180W 200W

The CES-EX-D-JX Series are explosion-proof LED floodlights designed for use in hazardous locations, specifically Zone 1 and Zone 2 areas. Similar to the previous product you mentioned, these lights are also ATEX-approved, indicating their suitability for use in potentially explosive atmospheres.

Explosion-Proof Design: These LED floodlights are designed to prevent the ignition of hazardous gases, vapors, or dust in the surrounding environment, making them safe for use in areas where explosive materials may be present.

Various Wattage Options: The series offers a range of wattage options, including 100W, 120W, 200W, and 240W. This flexibility allows you to select the appropriate level of illumination based on your specific requirements.

ATEX Approved: The ATEX approval is crucial, as it confirms that the lights meet the safety standards required for operation in potentially explosive atmospheres.

Features

- -40°C to +40°C/50°C/60°C ambient temperature

- Wide optics for uniform illumination

- 5 years warranty

- Housing – Aluminum alloy (ADC12)

- Lens – tempered glass

- Weight: 14.7KG

Parameters

- Power: 120W / 150W / 180W / 200W

- Input voltage: AC110-277V, 50/60Hz

- Power factor: 0.97

- Light efficacy: 130lm/W

- CCT: 3000K/4000K/5000K/5700K/6500K

- LEDs: 3030

- LED Driver: High-Efficiency Driver

Certificate & Standard

Certifications and compliances for hazardous location.

-

CNEX Certificate No. : CMExC23.1137

• Ex db IIC T6 Gb;

• Ex tb IIIC T80°C Db;

• IP66; -

ATEX Certificate No. : TUV CY 24 ATEX 0206973 X

• Ex ll 2G Ex db op is IC T6…T4 Gb

• Ex II 2D Ex op is tb IIIC T130 ℃Db

Mounting

Versatile mounting options:

- Pendant mount

- Pole mount

- Wall mount

60W - 100W Explosion-Proof Flood Light Fixtures

ATEX Explosion Proof LED Flood Light - 60W 70W 80W 100W

The CES-EX-D-JX Series are explosion-proof LED floodlights designed for use in hazardous locations, specifically Zone 1 and Zone 2 areas. Similar to the previous product you mentioned, these lights are also ATEX-approved, indicating their suitability for use in potentially explosive atmospheres.

Explosion-Proof Design: These LED floodlights are designed to prevent the ignition of hazardous gases, vapors, or dust in the surrounding environment, making them safe for use in areas where explosive materials may be present.

Various Wattage Options: The series offers a range of wattage options, including 70W, 80W and 100W. This flexibility allows you to select the appropriate level of illumination based on your specific requirements.

ATEX Approved: The ATEX approval is crucial, as it confirms that the lights meet the safety standards required for operation in potentially explosive atmospheres.

Features

- -40°C to +40°C/50°C/60°C ambient temperature

- Wide optics for uniform illumination

- 5 years warranty

- Housing – Aluminum alloy (ADC12)

- Lens – tempered glass

- Dimension: 263*283*148.5mm

- Weight: 7.9KG

Parameters

- Power: 60W / 70W / 80W / 100W

- Input voltage: AC110-277V, 50/60Hz

- Power factor: 0.97

- Light efficacy: 130lm/W

- CCT: 3000K/4000K/5000K/5700K/6500K

- LEDs: 3030

- LED Driver: High-Efficiency Driver

Certificate & Standard

Certifications and compliances for hazardous location.

-

CNEX Certificate No. : CMExC23.1137

• Ex db IIC T6 Gb;

• Ex tb IIIC T80°C Db;

• IP66; -

ATEX Certificate No. : TUV CY 24 ATEX 0206973 X

• Ex ll 2G Ex db op is IC T6…T4 Gb

• Ex II 2D Ex op is tb IIIC T130 ℃Db

Mounting

Versatile mounting options:

- Pendant mount

- Pole mount

- Wall mount

30W - 50W Explosion-Proof Flood Light Fixtures

ATEX Explosion Proof LED Flood Light - 30W 40W 50W

The CES-EX-D-JX Series are explosion-proof LED floodlights designed for use in hazardous locations, specifically Zone 1 and Zone 2 areas. Similar to the previous product you mentioned, these lights are also ATEX-approved, indicating their suitability for use in potentially explosive atmospheres.

Explosion-Proof Design: These LED floodlights are designed to prevent the ignition of hazardous gases, vapors, or dust in the surrounding environment, making them safe for use in areas where explosive materials may be present.

Various Wattage Options: The series offers a range of wattage options, including 30W, 40W, 50W, and 60W. This flexibility allows you to select the appropriate level of illumination based on your specific requirements.

ATEX Approved: The ATEX approval is crucial, as it confirms that the lights meet the safety standards required for operation in potentially explosive atmospheres.

Features

- Luminous flux: 3900lm / 5200lm / 6500lm

- -40°C to +40°C/50°C/60°C ambient temperature

- Wide optics for uniform illumination

- 5 years warranty

- Housing – Aluminum alloy (ADC12)

- Lens – tempered glass

- Dimension: 295*229.5*148.5mm

- Weight: 5.2KG

Parameters

- Power: 30W / 40W / 50W

- Input voltage: AC110-277V, 50/60Hz

- Power factor: 0.97

- Light efficacy: 130lm/W

- CCT: 3000K/4000K/5000K/5700K/6500K

- LEDs: 3030

- LED Driver: High-Efficiency Driver

Certificate & Standard

Certifications and compliances for hazardous location.

-

CNEX Certificate No. : CMExC23.1137

• Ex db IIC T6 Gb;

• Ex tb IIIC T80°C Db;

• IP66; -

ATEX Certificate No. : TUV CY 24 ATEX 0206973 X

• Ex ll 2G Ex db op is IC T6…T4 Gb

• Ex II 2D Ex op is tb IIIC T130 ℃Db

Mounting

Versatile mounting options:

- Pendant mount

- Pole mount

- Wall mount