IECEx ATEX Certified Explosion proof LED Lights - Zone 1 Zone 2 Hazardous Area Lighting

For Zone 1 Zone 2, Zone 21 Zone 22 hazardous area led lighting, 20W - 200W, 130lm/W,aluminum alloy + 8mm tempered glass, multi-installation for different projects, such as light tower, canopy light, marine grade.

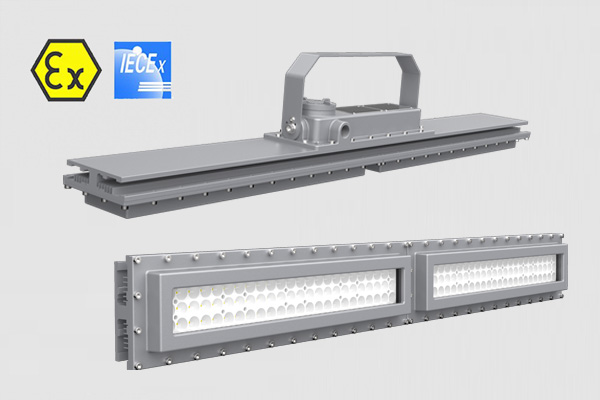

Flameproof enclosure, Ex db op is IIC T6 Gb, Zone 1 & Zone 21 with explosive gas atmosphere, Zone 21 and Zone22 with explosive dust atmosphere, 10mm temered glass, 7J impact resistance,up to 26000lm.

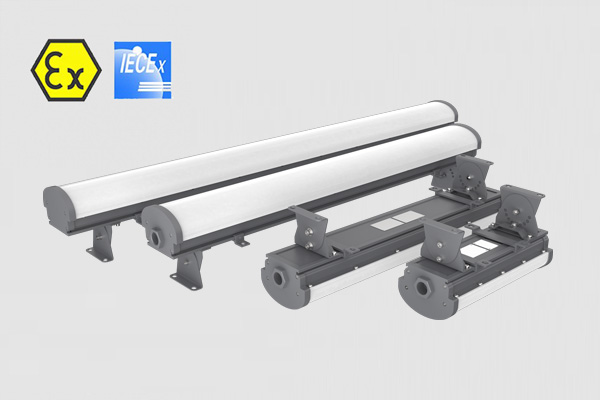

Flameproof enclosure, Ex db op is IIC T6 Gb, IP68 protection grade, tempered glass 10mm, withstand impacts up to 10J, 2 foot and 4 foot Length, 50Watt- 240Watt, 130lm/W light efficacy.

Zone 1 & Zone 21, 1ft, 2ft, 3ft, 4ft length can be selected, replace the traditional explosion-proof three-proof lamp, explosion-proof fluorescent tube, anti-corrosion, anti-glare, anti-drop, competitive price.

Flameproof LED hand lamp for Zone 1 & Zone 21 hazardous areas, 10mm tempered glass, pass the multi-angle drop test, 10W, 20W, 30W Power, can be connected to the cable, emergency power box.

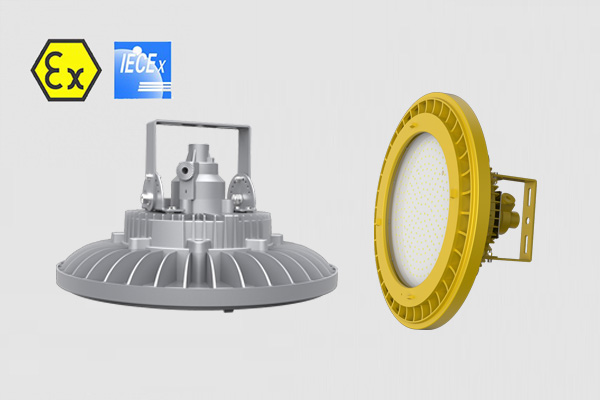

The CES-EX-SF series explosion-proof ceiling lamp has a strong shell, with features such as impact resistance, vibration resistance, and corrosion resistance. It can be used in hazardous environments of Zone 1&21, Zone 2&22.

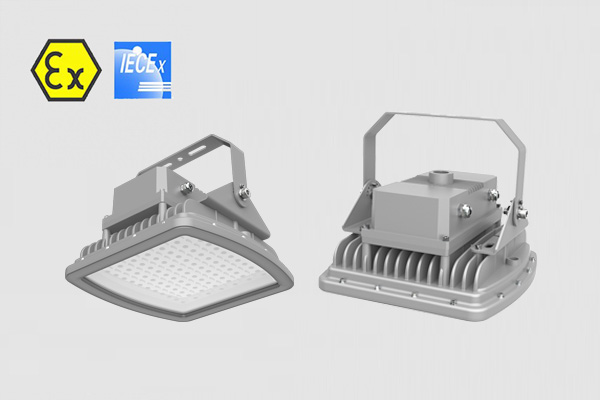

CES-EX-JX Series is your go-to solution for illuminating hazardous Zone 1 and Zone 21 areas. With ATEX approval, these Explosion-proof LED Flood Lights offer unbeatable safety standards.

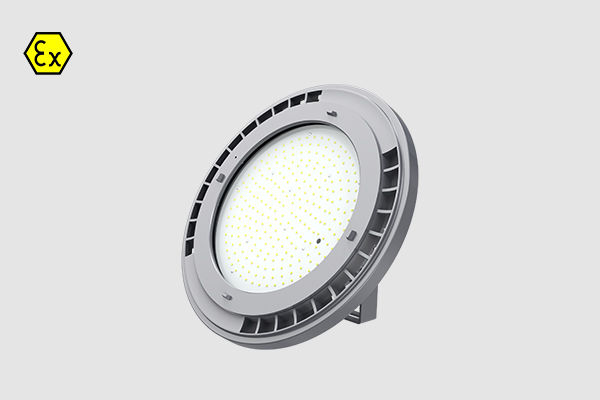

Discover the pinnacle of safety and illumination with our CES-EX-GBX Series Explosion-proof LED High Bay Lights. Designed for hazardous Zone 1 and Zone 21 areas, these lights boast ATEX approval, ensuring the highest safety standards.

GB-02 explosion-proof lights are made of alloy aluminum and tempered glass, with shock resistance and anti-vibration performance. The luminaires have passed the ATEX IECEx standards test, from 30W to 80W for hazardous area lighting.

LN-02 explosion-proof lights obtained an IECEx ATEX certificate, it's safe for the Zone 1 and Zone 2 hazardous locations. The copper-free aluminum alloy body is powder-coated to increase durability and beautiful appearance, are able to withstand violent shaking and shock resistance.

an innovative line of LED hazardous area lighting products, specifically designed for use in potentially explosive atmospheres (Zone 1/21 & 2/22) within harsh industrial settings such as coal mines and oil & gas facilities.

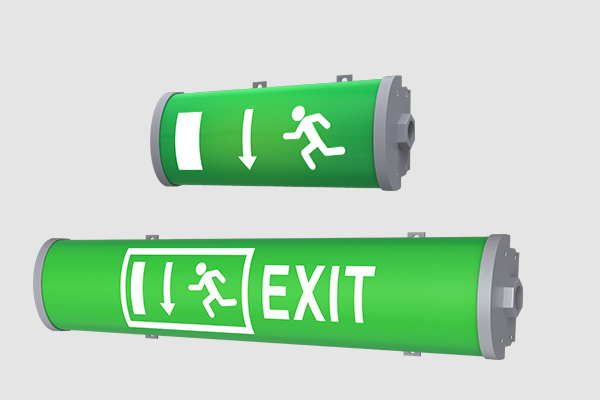

Explosion-proof safety exit lamps are for personnel evacuation, and fire operations to provide lighting fire emergency lamps! It usually uses an external power supply, when the power automatically switches to the battery power state!

2 Foot Hazardous Location Linear Light - Class 1 Div 2 - Pendant Chain Mount

2 Foot Explosion Proof Fluorescent Light Replacement - Class 1 Division 2 - Pendant Chain Mount

Applications:

- Wastewater treatment, oil and gas refineries, drilling rigs, petrochemical facilities, food and beverage facilities, tunnels, outdoor wall and stanchion mounted general area lighting.

CUL for Hazloc:

- SUITABLE FOR WET LOCATIONS;

- THIS LUMINAIRE IS ACCEPTABLE FOR OPERATION IN AMBIENT CONDITIONS NOT EXCEEDING __55__ °C (_131 °F);

- MIN 90°C (194°F) SUPPLY CONDUCTORS;

- NO SERVICEABLE PARTS” OR “NO USER SERVICEABLE PARTS. DO NOT OPEN FOR CLEANING.;

- CAUTION - ″TO REDUCE THE RISK OF IGNITION OF HAZARDOUS ATMOSPHERES, DISCONNECT THE LUMINAIRE FROM THE SUPPLY CIRCUIT BEFORE OPENING. KEEP TIGHTLY CLOSED WHEN IN OPERATION.″;

- THIS PRODUCT MUST BE INSTALLED IN ACCORDANCE WITH THE APPLICABLE INSTALLATION CODE BY A PERSON FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF THE PRODUCT AND THE HAZARDS INVOLVED;

- “CAUTION – RISK OF SHOCK” and “DISCONNECT POWER BEFORE SERVICING”.

Features

- Industry-leading efficacy: up to 110 - 130lm/W

- -40°C to + 50°C Ambient operating temperature

- Mounting: Pendant Chain

- 5 years warranty

- Entry Size: NPT 3/4”-14

- Housing –Aluminum alloy (ADC12 and 6063 )

- Lens – Polycarbonate (PC)

- Beam angle:120°

Parameters

- Power: 30W / 40W / 50W

- Input voltage: AC100-240/277V, 50/60Hz

- Power factor: 0.97

- Lumen flux: 2600LM / 4800LM / 6000LM

- CCT: 2700K - 6500K (Optional)

- LEDs: 3030 (6V)

- LED Driver: high Efficiency LED Driver

- Dimension: 629 mm x 125mm x 88.7 mm

- Weight: 3.0KG

Certificate & Standard

Have certified CES-EX-LN-02P fixtures with the North American UL844 standards for hazardous location and environments.

NEC/CEC:

- Class I, Division 2, Groups A, B, C and D

- T-Class: T4A / T5

- Damp and wet locations

- Certify No:E475887

Standard:

- US: UL 844; UL 1598;

- Canada: CSA C22.2 No. 137; CSA C22.2 No. 250.0

Special order

- Special Orders- Requirements

Contact us for special requirements

Tel: +86-755-83509822

Fax: +86-755-83509868

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Class 1 Division 2 Fluorescent Light Replacement - 4ft - Pendant Mount

Explosion Proof Fluorescent Light Replacement - Hazardous Location Class 1 Division 2 - 4ft - Ceiling Mount

Applications:

- Wastewater treatment, oil and gas refineries, drilling rigs, petrochemical facilities, food and beverage facilities, tunnels, outdoor wall and stanchion mounted general area lighting.

CUL for Hazloc:

- SUITABLE FOR WET LOCATIONS;

- THIS LUMINAIRE IS ACCEPTABLE FOR OPERATION IN AMBIENT CONDITIONS NOT EXCEEDING __55__ °C (_131 °F);

- MIN 90°C (194°F) SUPPLY CONDUCTORS;

- NO SERVICEABLE PARTS” OR “NO USER SERVICEABLE PARTS. DO NOT OPEN FOR CLEANING.;

- CAUTION - ″TO REDUCE THE RISK OF IGNITION OF HAZARDOUS ATMOSPHERES, DISCONNECT THE LUMINAIRE FROM THE SUPPLY CIRCUIT BEFORE OPENING. KEEP TIGHTLY CLOSED WHEN IN OPERATION.″;

- THIS PRODUCT MUST BE INSTALLED IN ACCORDANCE WITH THE APPLICABLE INSTALLATION CODE BY A PERSON FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF THE PRODUCT AND THE HAZARDS INVOLVED;

- “CAUTION – RISK OF SHOCK” and “DISCONNECT POWER BEFORE SERVICING”.

Features

- Industry-leading efficacy: up to 110 - 130lm/W

- -40°C to + 50°C Ambient operating temperature

- Mounting: Pendant

- 5 years warranty

- Entry Size: NPT 3/4”-14

- Housing –Aluminum alloy (ADC12 and 6063 )

- Lens – Polycarbonate (PC)

- Beam angle:120°

Parameters

- Power: 40W / 50W / 60W / 65W / 75W

- Input voltage: AC100-240/277V, 50/60Hz

- Power factor: 0.97

- Lumen flux: 4800LM / 6000LM / 7200LM / 7800LM / 9000LM

- CCT: 2700K - 6500K (Optional)

- LEDs: 3030 (6V)

- LED Driver: high Efficiency LED Driver

- Dimension: 1229 mm x 138.3mm x 98.1 mm

- Weight: 5.5KG

Certificate & Standard

Have certified CES-EX-LN-02P fixtures with the North American UL844 standards for hazardous location and environments.

NEC/CEC:

- Class I, Division 2, Groups A, B, C and D

- T-Class: T4A / T5

- Damp and wet locations

- Certify No:E475887

Standard:

- US: UL 844; UL 1598;

- Canada: CSA C22.2 No. 137; CSA C22.2 No. 250.0

Special order

- Special Orders- Requirements

Contact us for special requirements

Tel: +86-755-83509822

Fax: +86-755-83509868

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Class 1 Division 2 Fluorescent Light Replacement - 2ft - Pendant Mount

Explosion Proof Fluorescent Light Replacement for Hazardous Location Class 1 Division 2 - 2ft - Pendant Mount

Applications:

- Wastewater treatment, oil and gas refineries, drilling rigs, petrochemical facilities, food and beverage facilities, tunnels, outdoor wall and stanchion mounted general area lighting.

CUL for Hazloc:

- SUITABLE FOR WET LOCATIONS;

- THIS LUMINAIRE IS ACCEPTABLE FOR OPERATION IN AMBIENT CONDITIONS NOT EXCEEDING __55__ °C (_131 °F);

- MIN 90°C (194°F) SUPPLY CONDUCTORS;

- NO SERVICEABLE PARTS” OR “NO USER SERVICEABLE PARTS. DO NOT OPEN FOR CLEANING.;

- CAUTION - ″TO REDUCE THE RISK OF IGNITION OF HAZARDOUS ATMOSPHERES, DISCONNECT THE LUMINAIRE FROM THE SUPPLY CIRCUIT BEFORE OPENING. KEEP TIGHTLY CLOSED WHEN IN OPERATION.″;

- THIS PRODUCT MUST BE INSTALLED IN ACCORDANCE WITH THE APPLICABLE INSTALLATION CODE BY A PERSON FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF THE PRODUCT AND THE HAZARDS INVOLVED;

- “CAUTION – RISK OF SHOCK” and “DISCONNECT POWER BEFORE SERVICING”.

Features

- Industry-leading efficacy: up to 110 - 130lm/W

- -40°C to + 50°C Ambient operating temperature

- Mounting: Pendant

- 5 years warranty

- Entry Size: NPT 3/4”-14

- Housing –Aluminum alloy (ADC12 and 6063 )

- Lens – Polycarbonate (PC)

- Beam angle:120°

Parameters

- Power: 30W / 40W / 50W

- Input voltage: AC100-240/277V, 50/60Hz

- Power factor: 0.97

- Lumen flux: 2600LM / 4800LM / 6000LM

- CCT: 2700K - 6500K (Optional)

- LEDs: 3030 (6V)

- LED Driver: high Efficiency LED Driver

- Dimension: 629 mm x 125mm x 88.7 mm

- Weight: 3.0KG

Certificate & Standard

Have certified CES-EX-LN-02P fixtures with the North American UL844 standards for hazardous location and environments.

NEC/CEC:

- Class I, Division 2, Groups A, B, C and D

- T-Class: T4A / T5

- Damp and wet locations

- Certify No:E475887

Standard:

- US: UL 844; UL 1598;

- Canada: CSA C22.2 No. 137; CSA C22.2 No. 250.0

Special order

- Special Orders- Requirements

Contact us for special requirements

Tel: +86-755-83509822

Fax: +86-755-83509868

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Class 1 Div 2 Hazardous Location LED Linear Light 160W - 300W

Hazardous Location LED Linear Light - Combination Installation - 160W 200W 240W 300W

Applications

Wastewater treatment,oil and gas refineries, drilling rigs, petrochemical facilities, food and beverage facilities, tunnels, outdoor wall and stanchion mounted general area lighting, and where flammable vapors, gases, ignitable dusts, fibers or flyings are present.

Warning:

CUL for Hazloc:

- SUITABLE FOR WET LOCATIONS;

- THIS LUMINAIRE IS ACCEPTABLE FOR OPERATION IN AMBIENT CONDITIONS NOT EXCEEDING 50°C;

- FOR SUPPLY CONNECTION, USE WIRES RATED FOR AT LEAST90°C;

- NO SERVICEABLE PARTS” OR “NO USER SERVICEABLE PARTS. DO NOT OPEN FOR CLEANING.;

- CAUTION - ″TO REDUCE THE RISK OF IGNITION OF HAZARDOUS ATMOSPHERES, DISCONNECT THE LUMINAIRE FROM THE SUPPLY CIRCUIT BEFORE OPENING. KEEP TIGHTLY CLOSED WHEN IN OPERATION.″;

- THIS PRODUCT MUST BE INSTALLED IN ACCORDANCE WITH THE APPLICABLE INSTALLATION CODE BY A PERSON FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF THE PRODUCT AND THE HAZARDS INVOLVED;

- “CAUTION – RISK OF SHOCK” and “DISCONNECT POWER BEFORE SERVICING”.

Features

- Luminous flux: 19200LM / 24000LM / 28800LM / 36000LM

- -40°C to +50°C Ambient operating temperature

- Wide optics for uniform illumination

- 5 years warranty

- Entry Size: NPT 3/4”-14 ;

- Housing –Aluminum alloy (ADC12 and 6063)

- Lens –tempered glass

Parameters

- Power:160W / 200W / 240W / 300W

- Input voltage: AC100-240/277V, 50/60Hz

- Power factor: 0.97

- Light efficacy: 120 - 140lm/W

- CCT: 3000K/4000K/5000K/5700K/6500K

- LEDs: 3030 (6V)

- LED Driver: Meanwell HLG series

- Weight: 21.2KG

Certificate & Standard

Have certified CES-EX-LN-02 fixtures with the NEC and CEC standards for hazardous location and environments

- Class I, Division 2, Groups A, B, C and D;

- Class II, Division 2, Groups F and G

- Class III

- T-Class: T *(T3C/T4A/T5)

- Wet Location

Certificate No:E475887

US: UL 844; UL 1598;

Canada: CSA C22.2 No. 137; CSA C22.2 No. 250.0

Mounting

Versatile mounting options:

- Ceiling mount

- Mounting Angle:0°to ±90°

- When installing in ignitable dusts, fibers or flyings, do not allow the lamp cover to be installed upwards.

Hazardous Location LED Linear Light Combination 320W - 600W

High Power Explosion Proof LED Light for Class 1 Division 2 - Combination Installation - 320W 400W 480W 600W

Applications

Wastewater treatment,oil and gas refineries, drilling rigs, petrochemical facilities, food and beverage facilities, tunnels, outdoor wall and stanchion mounted general area lighting, and where flammable vapors, gases, ignitable dusts, fibers or flyings are present.

Warning:

CUL for Hazloc:

- SUITABLE FOR WET LOCATIONS;

- THIS LUMINAIRE IS ACCEPTABLE FOR OPERATION IN AMBIENT CONDITIONS NOT EXCEEDING 50°C;

- FOR SUPPLY CONNECTION, USE WIRES RATED FOR AT LEAST90°C;

- NO SERVICEABLE PARTS” OR “NO USER SERVICEABLE PARTS. DO NOT OPEN FOR CLEANING.;

- CAUTION - ″TO REDUCE THE RISK OF IGNITION OF HAZARDOUS ATMOSPHERES, DISCONNECT THE LUMINAIRE FROM THE SUPPLY CIRCUIT BEFORE OPENING. KEEP TIGHTLY CLOSED WHEN IN OPERATION.″;

- THIS PRODUCT MUST BE INSTALLED IN ACCORDANCE WITH THE APPLICABLE INSTALLATION CODE BY A PERSON FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF THE PRODUCT AND THE HAZARDS INVOLVED;

- “CAUTION – RISK OF SHOCK” and “DISCONNECT POWER BEFORE SERVICING”.

Features

- Luminous flux: 38400LM / 48000LM / 57600LM / 72000LM

- -40°C to +50°C Ambient operating temperature

- Wide optics for uniform illumination

- 5 years warranty

- Entry Size: NPT 3/4”-14 ;

- Housing –Aluminum alloy (ADC12 and 6063)

- Lens –tempered glass

Parameters

- Power: 320W / 400W / 480W / 600W

- Input voltage: AC100-240/277V, 50/60Hz

- Power factor: 0.97

- Light efficacy: 120 - 140lm/W

- CCT: 3000K/4000K/5000K/5700K/6500K

- LEDs: 3030 (6V)

- LED Driver: Meanwell HLG series

- Weight: 21.2KG

Certificate & Standard

Have certified CES-EX-LN-02 fixtures with the NEC and CEC standards for hazardous location and environments

- Class I, Division 2, Groups A, B, C and D;

- Class II, Division 2, Groups F and G

- Class III

- T-Class: T *(T3C/T4A/T5)

- Wet Location

Certificate No:E475887

US: UL 844; UL 1598;

Canada: CSA C22.2 No. 137; CSA C22.2 No. 250.0

Mounting

Versatile mounting options:

- Ceiling mount

- Mounting Angle:0°to ±90°

- When installing in ignitable dusts, fibers or flyings, do not allow the lamp cover to be installed upwards.

Class 1 Div 2 Hazardous Location LED Linear Light Combination 240W - 450W

Hazardous Location LED Linear Light - Combination Installation - 240W 300W 360W 450W

Applications

Wastewater treatment,oil and gas refineries, drilling rigs, petrochemical facilities, food and beverage facilities, tunnels, outdoor wall and stanchion mounted general area lighting, and where flammable vapors, gases, ignitable dusts, fibers or flyings are present.

Warning:

CUL for Hazloc:

- SUITABLE FOR WET LOCATIONS;

- THIS LUMINAIRE IS ACCEPTABLE FOR OPERATION IN AMBIENT CONDITIONS NOT EXCEEDING 50°C;

- FOR SUPPLY CONNECTION, USE WIRES RATED FOR AT LEAST90°C;

- NO SERVICEABLE PARTS” OR “NO USER SERVICEABLE PARTS. DO NOT OPEN FOR CLEANING.;

- CAUTION - ″TO REDUCE THE RISK OF IGNITION OF HAZARDOUS ATMOSPHERES, DISCONNECT THE LUMINAIRE FROM THE SUPPLY CIRCUIT BEFORE OPENING. KEEP TIGHTLY CLOSED WHEN IN OPERATION.″;

- THIS PRODUCT MUST BE INSTALLED IN ACCORDANCE WITH THE APPLICABLE INSTALLATION CODE BY A PERSON FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF THE PRODUCT AND THE HAZARDS INVOLVED;

- “CAUTION – RISK OF SHOCK” and “DISCONNECT POWER BEFORE SERVICING”.

Features

- Luminous flux: 28800LM / 36000LM / 43200LM / 54000LM

- -40°C to +50°C Ambient operating temperature

- Wide optics for uniform illumination

- 5 years warranty

- Entry Size: NPT 3/4”-14 ;

- Housing –Aluminum alloy (ADC12 and 6063)

- Lens –tempered glass

Parameters

- Power:240W / 300W / 360W / 450W

- Input voltage: AC100-240/277V, 50/60Hz

- Power factor: 0.97

- Light efficacy: 120 - 140lm/W

- CCT: 3000K/4000K/5000K/5700K/6500K

- LEDs: 3030 (6V)

- LED Driver: Meanwell HLG series

- Weight: 21.2KG

Certificate & Standard

Have certified CES-EX-LN-02 fixtures with the NEC and CEC standards for hazardous location and environments

- Class I, Division 2, Groups A, B, C and D;

- Class II, Division 2, Groups F and G

- Class III

- T-Class: T *(T3C/T4A/T5)

- Wet Location

Certificate No:E475887

US: UL 844; UL 1598;

Canada: CSA C22.2 No. 137; CSA C22.2 No. 250.0

Mounting

Versatile mounting options:

- Ceiling mount

- Mounting Angle:0°to ±90°

- When installing in ignitable dusts, fibers or flyings, do not allow the lamp cover to be installed upwards.

Overview of flameproof type explosion-proof lamps

The flameproof lamps of explosion-proof type is mainly based on the product structure, which is specially equipped with a certain flameproof joint surface or flameproof thread. Through an integral flameproof enclosure, it can withstand the explosive pressure of the explosive mixture that may be generated inside the lamp. And prevent the explosion to the surrounding explosive mixture to achieve the purpose of explosion-proof.

1. Explosion-proof principle of flameproof lamps

Flameproof lamps, which can use incandescent lamps, tungsten halogen lamps, fluorescent bulbs (including compact fluorescent lamps), high-pressure mercury lamps, high-pressure sodium lamps, self-ballasted high-pressure mercury lamps, metal halide lamps and led light whose power supply does not exceed 1,000V. The structural feature is that it must first have an explosion-proof enclosure that can withstand the explosion strength test and inspection specified in Explosion proof test. This integral flame-proof enclosure includes the lamp body parts that must be made of metal materials in principle and the corresponding equipment. Two parts are transparent parts such as solid lampshade. According to the shape of the light source and the distribution of the luminous body, common flameproof lamps can generally be summarized as vertical lamps equipped with gas discharge light sources such as incandescent lamps and high-pressure mercury lamps, and horizontal lamps equipped with straight fluorescent bulbs. Two basic types of lamps. The common components are the lamp body, transparent parts, sealing parts, lamp holders, internal reflectors and external lamp umbrellas. And a good flameproof lamp. The main reason is to have a reasonable structure of the lamp body and a matching flame-proof joint surface, a transparent part that can withstand the impact test and thermal shock test, and use a rubber seal with strong anti-aging ability to fix the lamp body and the transparent part. Equipped with a lamp holder with reliable electrical performance, the luminous flux of the internal light source of the lamp can be irradiated to the outside of the lamp through the transparent part to the maximum through the rationally designed internal reflector and external lamp umbrella, giving an ideal lighting effect in dangerous places. And how to organically combine these elements with a reasonable layout is the key to the design and development of flameproof and explosion-proof lamps at present and even in the future.

2. Basic requirements for flameproof enclosures of lamps

For flameproof lamps, the flameproof enclosure is a key component of this type of explosion-proof electrical equipment, so the flameproof enclosure must meet the general requirements and special requirements for flameproof performance.

a. General requirements

- Flameproof lamps are special lamps that must meet the general requirements of ordinary lamps.

- The shell shape of the lamp strives to be beautiful, compact and reliable, light and manufacturable.

- It is required to have enough volume for placing lamp holders, bulbs, reflectors, terminals and other electrical components and lighting accessories. At the same time, the rationality of the layout should be considered to facilitate the use and maintenance of installation and replacement of light sources.

- There must be a transparent part with a certain surface area, so that the luminous flux of the light source inside the lamp can be effectively projected through the reflective part.

- It is necessary to comprehensively consider measures such as heat dissipation, dust-proof, waterproof and anti-corrosion, and give sufficient guarantee in the structure.

In appropriate locations, reasonably arrange internal and external grounding, and have corresponding permanent grounding signs.

b. special requirements

For flameproof enclosures, the international explosion-proof standards require that they can withstand the explosive pressure of the internal explosive gas mixture and prevent the internal explosive flame from spreading to the explosive mixture around the enclosure. To meet this performance, the following special requirements must be specifically considered as follow,

- Anti-explosion performance. The lamp shell is required to have sufficient strength and rigidity to withstand the explosion pressure that may be caused by the inner cavity of the lamp. Therefore, it is necessary to select the appropriate material and wall thickness to form a solid geometric shape distribution. This cavity structure must be both beautiful and generous. It is necessary to avoid the uneven stress caused by excessive changes in the shape as much as possible, so as to ensure that it can finally pass the dynamic strength test specified by IECEx.

- Explosion-proof function. The flameproof enclosure of the lamp must be designed in strict accordance with the requirements of IECEx to select the appropriate flameproof joint surface structure parameters, the method of introducing the device, the sealing structure form of the transparent part and the lamp body part, the roughness of the flameproof joint surface, and the insulation The precision of the explosion thread, etc., in order to effectively prevent the internal explosion flame from spreading to the explosive mixture around the shell, and finally pass the explosion-proof performance test specified in IECEx.

- The flameproof enclosures of lamps are mostly composed of 2 or more connected cavities, which are often prone to pressure overlap. Generally speaking, this will cause the explosion pressure to rise abnormally and sharply and exceed the expected maximum pressure. For this reason, the area of the connecting hole should be increased as much as possible, so that the shape of the shell can eliminate the phenomenon of pressure overlap. If the pressure overlap phenomenon cannot be eliminated in practice, explosion-proof measures should be taken between the cavity to eliminate the pressure overlap.

- For IIC flameproof lamps, IECEx strictly stipulates that flat flameproof joints whose flameproof gap tends to increase during explosion should not be used. For this reason, most of the flameproof IIC explosion-proof lamps in my country currently use flameproof threads. The structure of the lamp can be opened smoothly when the lamp is replaced or repaired.

3. Design, manufacture and installation of transparent parts of flameproof lamps

As a flameproof type explosion-proof lamp, it must have a certain light-transmitting part. At present, most of them are made of glass materials and are fixedly installed on the cavity of the flameproof lamp. Therefore, for these transparent glass parts of flameproof lamps, not only must meet the requirements of IECEx general requirements for the impact test and thermal shock test of transparent parts, but more importantly, they must withstand the dynamic strength test specified in IECEx. This requires these glass transparent parts to have sufficient strength, that is, they must have sufficient thickness and a certain geometric shape distribution, and undergo processing such as tempering. When designing shaped glass transparent parts, we must pay attention to the reasonable choice of glass thickness and the determination of the shape. It is a prerequisite for everything to avoid uneven stress in the finished product of the transparent part, and at the same time, try to ensure that there is no sudden change in thickness. The main advantage of glass is that it can maintain its physical and light transmission properties under high temperature, ultraviolet radiation and long-term humid conditions, the surface is resistant to scratches by hard particles, and it is allowed to be immersed in water or organic solvents without stress Cracks or corrosion. The main disadvantage of glass is its brittleness and low tensile strength. In order to make up for these shortcomings, when designing the assembly structure of the transparent glass part and the lamp body, a sealing gasket is usually inserted between the transparent glass part and the metal parts of the lamp housing to prevent point contact with the metal element of the housing and damage the transparent glass part. In order to prevent the impact of solid foreign objects from breaking the glass transparent parts, the current commonly used method is to add a grille for protection. If the grille is not installed, the glass transparent parts must pass the high-energy impact test specified by IECEx.

When the transparent parts of general flameproof lamps adopt a sealed structure, the thickness of the gasket must not be less than 2.0mm, and the width of the embedded part of the gasket between the metal shell and the transparent glass part must not be less than 10.0mm. At the same time, the glass transparent parts should generally be installed in the inner cavity, because when there is pressure inside, the elastic sealing gasket tends to be compressed, which will strengthen the sealing performance. The material of the elastic gasket is generally nitrile rubber. when the power of the lamp is large, asbestos rubber sheet, silicon rubber and fluoro rubber can be used to self-extinguish materials. It must also be noted that when installing the glass transparent part, measures are taken to ensure that the periphery of the lampshade, glass tube, and transparent plate is compressed structurally, and the force must be uniform to avoid dangerous mechanical stress inside the transparent part. For the transparent glass parts of flameproof lamps, it can also be sealed and fixed by direct glue sealing with the lamp body of the outer shell. This structure has higher requirements for glue sealing materials, and silicone rubber is suitable. The fixing of the transparent part of the lamp and the housing part must be ensured in structure. When the light source is replaced, the transparent part and the sealing part shall not fall off from the housing part.

Ex db op is IIC T6 Gb, IP68 protection grade, tempered glass 10mm, withstand impacts up to 10J, 2 foot and 4 foot Length, 50Watt- 240Watt, 130lm/W light efficacy.

Ex db op is IIC T6 Gb, Zone 1 & Zone 21 with explosive gas atmosphere, Zone 21 and Zone22 with explosive dust atmosphere, 10mm temered glass, 7J impact resistance, up to 26000lm.

4. Selection of wiring method for flameproof lamps

The introduction method of flameproof lamps is clearly stipulated in IECEx, that is, lamps must be introduced indirectly, but fluorescent lamps with flameproof sockets and cold-start fluorescent lamps of type I can adopt direct introduction. This provision for the introduction method is mainly due to the fact that it is impossible to completely avoid sparks, arcs or dangerous temperatures inside the flameproof lamps during normal operation. The way of indirect introduction, that is, the electrical connection with the luminaire through a junction box or a plug with a cable or a wire, and the luminaire is structurally divided into two independent cavities, the main cavity and the wiring cavity of the luminaire, that is, the two cavities are explosion-proof Structure, so that the reliability of explosion-proof safety is fully guaranteed.

5. Inspection and repair of flameproof lamps

In principle, explosion-proof lamps are allowed to be repaired, and the specific requirements are as follows:

a. Requirements for lamp repair

The detachable parts of the lamp are allowed to be replaced with accessories, and the accessories must be the same as the original and must comply with relevant regulations.

The replacement here is to replace maintenance activities with accessories. Generally, flameproof lamps require non-professionals not to open or disassemble arbitrarily. The usual maintenance is to replace the light source and the starter of the fluorescent lamp and the trigger of the gas discharge lamp and other consumable electrical parts , After the luminaire is assembled and disassembled, pay attention to whether the gasket between the transparent part of the luminaire and the lamp body is restored to the original compressed state. In addition, pay attention not to damage the explosion-proof surface, the cable and the wire inlet during the assembly and disassembly process. If the sealing gasket is damaged, it must be replaced in time to ensure the reliability of the explosion-proof performance.

b. Lamp holder replacement

The lamp holder is allowed to be replaced as a whole. The flameproof lamp holder used for replacement must have a certificate or document approved by the explosion-proof inspection unit. The lamp holder accessories must ensure good contact and have the heat resistance of the original.

The lamp holder is allowed to be replaced as a whole. The main consideration is that the lamp holder is a complete component. The assembly of the lamp holder has many mutual constraints. If the parts are replaced, the overall electrical performance of the lamp holder will often be affected and coordinated. At the same time, the lamp holder The electrical conductivity and heat resistance of the socket accessories are very important. Random replacement will inevitably reduce the overall performance of the lamp socket. Therefore, the requirements for the lamp socket accessories are relatively high, completely from avoiding sparks inside the lamp. , Consider the angle of the arc.

c. Ballast replacement

The ballast of flameproof lamps is allowed to be replaced with accessories of the same model and capacity. When changing the ballast method, it must be approved by the explosion-proof inspection unit. The technical performance of different types of ballasts is not completely the same. When replacing different types of ballasts, it may cause changes in the temperature rise, insulation performance, and working performance of the flameproof lamps. In the flameproof lamps, this change It must affect the explosion-proof level, so it is stipulated that only accessories of the same model and capacity are allowed to be replaced. When the ballast method is changed, the temperature rise of the entire ballast component will change more. Therefore, the temperature rise and other tests must be repeated. Determine the new explosion-proof level, and this test appraisal can only be approved by the test of the explosion-proof inspection organization.

d. Replacement of the whole lamp

At present, LED lighting fixtures are widely used in the world, and the combination of LED and explosion-proof technology is also very mature. IECEx, ATEX, UL have their own mature explosion-proof test system. If it is a new explosion-proof lighting project and a replacement explosion-proof project for the whole lamp, LED explosion-proof lamps will be more considered. The original traditional explosion-proof lamps are gradually replaced by LED explosion-proof lamps.

All CESP explosion-proof lamps are of LED type, among which flameproof led lights include explosion proof high bay series, LED explosion-proof line light, and LED explosion-proof hand lamp. If you want to know more, please contact This email address is being protected from spambots. You need JavaScript enabled to view it.

Hazardous Location Class 1 Division 1 LED Hand Lamp / LED Drop Light - 360 Beam Angle

Hazardous Location Class 1 Division 1 Explosion Proof Hand Lamp / Drop Light / Work Light

Applications:

- Wastewater treatment, oil and gas refineries, drilling rigs, petrochemical facilities, food and beverage facilities, tunnels, outdoor wall and stanchion mounted general area lighting.

CUL for Hazloc:

- SUITABLE FOR WET LOCATIONS;

- THIS LUMINAIRE IS ACCEPTABLE FOR OPERATION IN AMBIENT CONDITIONS NOT EXCEEDING __55__ °C (_131 °F);

- MIN 90°C (194°F) SUPPLY CONDUCTORS;

- NO SERVICEABLE PARTS” OR “NO USER SERVICEABLE PARTS. DO NOT OPEN FOR CLEANING.;

- CAUTION - ″TO REDUCE THE RISK OF IGNITION OF HAZARDOUS ATMOSPHERES, DISCONNECT THE LUMINAIRE FROM THE SUPPLY CIRCUIT BEFORE OPENING. KEEP TIGHTLY CLOSED WHEN IN OPERATION.″;

- THIS PRODUCT MUST BE INSTALLED IN ACCORDANCE WITH THE APPLICABLE INSTALLATION CODE BY A PERSON FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF THE PRODUCT AND THE HAZARDS INVOLVED;

- “CAUTION – RISK OF SHOCK” and “DISCONNECT POWER BEFORE SERVICING”.

Features

- Industry-leading efficacy: up to 130lm/W±5

- -40°C to +50°CCAmbient operating temperature

- Swivel hook for hanging and hands free operation

- Prevent drop damage

- 5 years warranty

- Housing –Aluminum alloy (ADC12 )

- Lens – tempered glass (10mm)

- Beam angle:360°

Parameters

- Power: 10W / 20W / 30W

- Input voltage: 120Vac; Frequency: 50/60Hz;

- Lumen flux: 1300LM/2600LM/3900LM

- CCT: 6500K (Optional)

- LEDs: 3030

- LED Driver: High Efficiency LED Driver

- Dimension: Φ101.5 x 516.5 mm

- Weight: 2.4KG

Certificate & Standard

Have certified CES-SC fixtures with the North American UL844 standards for hazardous location and environments.

NEC/CEC:

- Class I, Division 2, Groups A, B, C and D

- Class II, Division 1, Groups E, F and G

- Class I, Division 2, Groups A, B, C and D

- Class II, Division 2, Groups F and G

- Class III

- T-Class: T6 / T80°C

- Damp and wet locations

- Paint spray rated

- Certificate No:E475887

Standard:

- US: UL 844; UL 153;

- Canada: CSA C22.2 No. 137; CSA C22.2 No.250.4

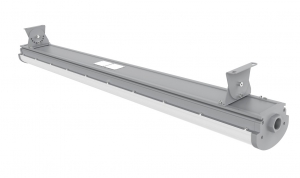

Class 1 Division 2 Fluorescent Light Replacement - 4ft - Ceiling Mount

Hazardous Location Class 1 Division 2 Fluorescent Light Replacement - 4ft - Ceiling Mount

Applications:

- Wastewater treatment, oil and gas refineries, drilling rigs, petrochemical facilities, food and beverage facilities, tunnels, outdoor wall and stanchion mounted general area lighting.

CUL for Hazloc:

- SUITABLE FOR WET LOCATIONS;

- THIS LUMINAIRE IS ACCEPTABLE FOR OPERATION IN AMBIENT CONDITIONS NOT EXCEEDING __55__ °C (_131 °F);

- MIN 90°C (194°F) SUPPLY CONDUCTORS;

- NO SERVICEABLE PARTS” OR “NO USER SERVICEABLE PARTS. DO NOT OPEN FOR CLEANING.;

- CAUTION - ″TO REDUCE THE RISK OF IGNITION OF HAZARDOUS ATMOSPHERES, DISCONNECT THE LUMINAIRE FROM THE SUPPLY CIRCUIT BEFORE OPENING. KEEP TIGHTLY CLOSED WHEN IN OPERATION.″;

- THIS PRODUCT MUST BE INSTALLED IN ACCORDANCE WITH THE APPLICABLE INSTALLATION CODE BY A PERSON FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF THE PRODUCT AND THE HAZARDS INVOLVED;

- “CAUTION – RISK OF SHOCK” and “DISCONNECT POWER BEFORE SERVICING”.

Features

- Industry-leading efficacy: up to 110 - 130lm/W

- -40°C to + 50°C Ambient operating temperature

- Mounting: Ceiling

- 5 years warranty

- Entry Size: NPT 3/4”-14

- Housing –Aluminum alloy (ADC12 and 6063 )

- Lens – Polycarbonate (PC)

- Beam angle:120°

Parameters

- Power: 40W / 50W / 60W / 65W / 75W

- Input voltage: AC100-240/277V, 50/60Hz

- Power factor: 0.97

- Lumen flux: 4800LM / 6000LM / 7200LM / 7800LM / 9000LM

- CCT: 2700K - 6500K (Optional)

- LEDs: 3030 (6V)

- LED Driver: high Efficiency LED Driver

- Dimension: 1229 mm x 138.3mm x 98.1 mm

- Weight: 5.5KG

Certificate & Standard

Have certified CES-EX-LN-02P fixtures with the North American UL844 standards for hazardous location and environments.

NEC/CEC:

- Class I, Division 2, Groups A, B, C and D

- T-Class: T4A / T5

- Damp and wet locations

- Certify No:E475887

Standard:

- US: UL 844; UL 1598;

- Canada: CSA C22.2 No. 137; CSA C22.2 No. 250.0

Special order

- Special Orders- Requirements

Contact us for special requirements

Tel: +86-755-83509822

Fax: +86-755-83509868

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Class 1 Division 2 Fluorescent Light Replacement - 2ft - Ceiling Mount

Hazardous Location Class 1 Division 2 Fluorescent Light Replacement - 2ft - Ceiling Mount

Applications:

- Wastewater treatment, oil and gas refineries, drilling rigs, petrochemical facilities, food and beverage facilities, tunnels, outdoor wall and stanchion mounted general area lighting.

CUL for Hazloc:

- SUITABLE FOR WET LOCATIONS;

- THIS LUMINAIRE IS ACCEPTABLE FOR OPERATION IN AMBIENT CONDITIONS NOT EXCEEDING __55__ °C (_131 °F);

- MIN 90°C (194°F) SUPPLY CONDUCTORS;

- NO SERVICEABLE PARTS” OR “NO USER SERVICEABLE PARTS. DO NOT OPEN FOR CLEANING.;

- CAUTION - ″TO REDUCE THE RISK OF IGNITION OF HAZARDOUS ATMOSPHERES, DISCONNECT THE LUMINAIRE FROM THE SUPPLY CIRCUIT BEFORE OPENING. KEEP TIGHTLY CLOSED WHEN IN OPERATION.″;

- THIS PRODUCT MUST BE INSTALLED IN ACCORDANCE WITH THE APPLICABLE INSTALLATION CODE BY A PERSON FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF THE PRODUCT AND THE HAZARDS INVOLVED;

- “CAUTION – RISK OF SHOCK” and “DISCONNECT POWER BEFORE SERVICING”.

Features

- Industry-leading efficacy: up to 110 - 130lm/W

- -40°C to + 50°C Ambient operating temperature

- Mounting: Ceiling

- 5 years warranty

- Entry Size: NPT 3/4”-14

- Housing –Aluminum alloy (ADC12 and 6063 )

- Lens – Polycarbonate (PC)

- Beam angle:120°

Parameters

- Power: 30W / 40W / 50W

- Input voltage: AC100-240/277V, 50/60Hz

- Power factor: 0.97

- Lumen flux: 2600LM / 4800LM / 6000LM

- CCT: 2700K - 6500K (Optional)

- LEDs: 3030 (6V)

- LED Driver: high Efficiency LED Driver

- Dimension: 629 mm x 125mm x 88.7 mm

- Weight: 3.0KG

Certificate & Standard

Have certified CES-EX-LN-02P fixtures with the North American UL844 standards for hazardous location and environments.

NEC/CEC:

- Class I, Division 2, Groups A, B, C and D

- T-Class: T4A / T5

- Damp and wet locations

- Certify No:E475887

Standard:

- US: UL 844; UL 1598;

- Canada: CSA C22.2 No. 137; CSA C22.2 No. 250.0

Special order

- Special Orders- Requirements

Contact us for special requirements

Tel: +86-755-83509822

Fax: +86-755-83509868

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.